Efficient detergent used in industrial circulating water and preparation method of efficient detergent

A technology of industrial circulating water and cleaning agent, applied in detergent compositions, chemical instruments and methods, soap detergent compositions, etc., to achieve good resistance to hard water, good antistatic, decontamination effect and decontamination ability at elevated temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

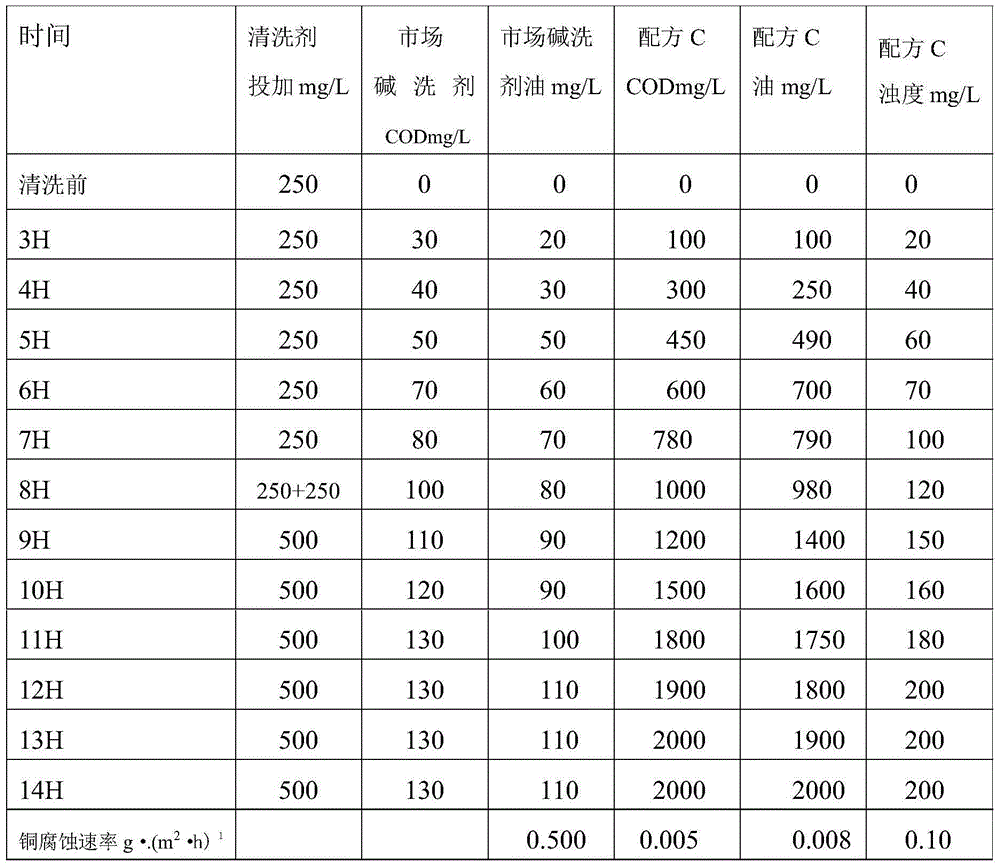

Examples

Embodiment 1

[0007] Embodiment 1. A high-efficiency cleaning agent used in industrial circulating water. The cleaning agent is composed of the following materials in parts by weight: 5 parts of polyoxyethylene fatty alcohol ether, 4 parts of polyoxyethylene octylphenol ether , 5 parts of triethanolamine oleic acid soap, 15 parts of isopropanol, 5 parts of trisodium phosphate, 2 parts of sodium tripolyphosphate, 3 parts of sodium carbonate, 3 parts of sodium hydroxide, 10 parts of sodium dodecylbenzenesulfonate and 35 parts of tap water.

[0008] 2. A preparation method of an efficient cleaning agent used in industrial circulating water, the preparation method is made up of the following steps: wherein the material is according to the above-mentioned parts by weight, (1) at first adding tap water in the stirring container, after starting the stirring container At this time, first add trisodium phosphate to dissolve it in tap water; then, add sodium hydroxide and sodium tripolyphosphate to t...

Embodiment 2

[0010] Embodiment 2, a high-efficiency cleaning agent used in industrial circulating water, the cleaning agent is composed of the following materials in parts by weight: 10 parts of polyoxyethylene fatty alcohol ether, 6 parts of polyoxyethylene octylphenol ether , 8 parts of triethanolamine oleic acid soap, 20 parts of isopropanol, 10 parts of trisodium phosphate, 4 parts of sodium tripolyphosphate, 5 parts of sodium carbonate, 5 parts of sodium hydroxide, 15 parts of sodium dodecylbenzenesulfonate and 48 parts of tap water.

[0011] The preparation method is the same as in Example 1. The performance parameters of the obtained high-efficiency cleaning agent: PH: 11.41, density 0.90, solid content: 35.02%, meet the design requirements.

Embodiment 3

[0012] Embodiment 3, a high-efficiency cleaning agent used in industrial circulating water, the cleaning agent is composed of the following materials in parts by weight: 8 parts of polyoxyethylene fatty alcohol ether, 5 parts of polyoxyethylene octylphenol ether , 6 parts of triethanolamine oleic acid soap, 18 parts of isopropanol, 8 parts of trisodium phosphate, 3 parts of sodium tripolyphosphate, 4 parts of sodium carbonate, 4 parts of sodium hydroxide, 14 parts of sodium dodecylbenzenesulfonate and 40 parts of tap water.

[0013] The preparation method is the same as in Example 1.

[0014] The medicaments used in the above-mentioned high-efficiency cleaning agents are all commercially available products. (Manufacturer: Polyoxyethylene Fatty Alcohol Ether: Haishi Chemical Co., Ltd.; Polyoxyethylene Octylphenol Ether: Haishi Chemical Co., Ltd. Triethanolamine Oleosaponic Acid: Haishi Chemical Co., Ltd.; Isopropanol: Yangzhou Gold Petrochemical Yangzi Chemical Co., Ltd.; Tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com