A method for rapidly preparing polysilicate aluminum ferric sulfate by one-pot cooking microwave radiation method

A technology of polysilicate aluminum sulfate and microwave radiation method, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long chemical reaction time, complicated process, secondary Eliminate secondary pollution and other problems, and achieve the effect of simple process flow, high turbidity removal rate, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

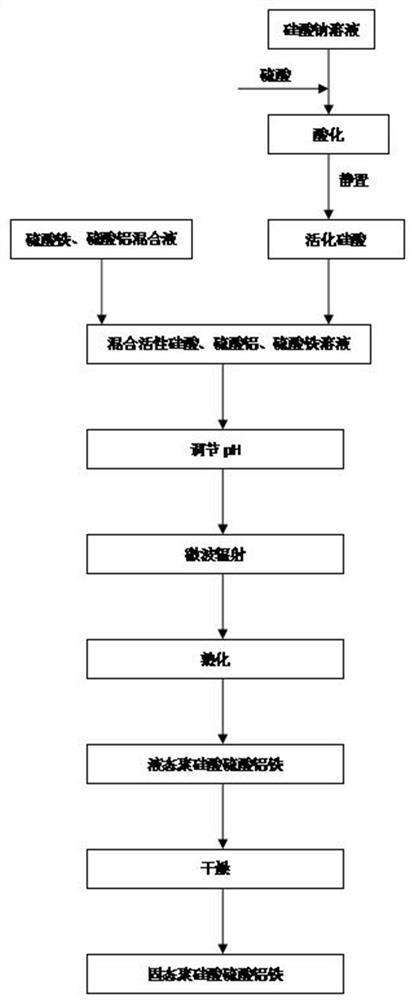

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Take sodium silicate, ferric sulfate, aluminum sulfate, sulfuric acid and sodium carbonate as the main raw materials: first dissolve an appropriate amount of sodium silicate in a certain amount of deionized water, and quickly adjust its pH to 1.5, stand for activation at room temperature for 20min to obtain activated silicic acid; then add dissolved ferric sulfate and aluminum sulfate mixed solution to the activated silicic acid to obtain a mixed solution of activated silicic acid, aluminum sulfate and ferric sulfate; use concentrated sulfuric acid and The sodium carbonate solution adjusts the pH to 1.2, and controls the ratio of the amount of substances n (Fe 3+ ):n(Al 3+ )=1:1, n(Fe 3+ ):n(SiO 2 )=9:1; control the solute mass fraction of the reaction system to be 30%; then put the mixed active silicic acid, aluminum sulfate, ferric sulfate solution into the microwave reactor with 400W power radiation for 3min, take out, and ripen at room temperature for 2...

Embodiment 2

[0025] Example 2: Take sodium silicate, ferric sulfate, aluminum sulfate, sulfuric acid and sodium carbonate as the main raw materials: first dissolve an appropriate amount of sodium silicate in a certain amount of deionized water, and quickly adjust its pH to 2.5, stand for activation at room temperature for 20min to obtain activated silicic acid; then add dissolved ferric sulfate and aluminum sulfate mixed solution to the activated silicic acid to obtain a mixed solution of activated silicic acid, aluminum sulfate and ferric sulfate; use concentrated sulfuric acid and The sodium carbonate solution is adjusted to pH 1.0, and the ratio of the amount of controlled substances is n (Fe 3+ ):n(Al 3+ )=1:1, n(Fe 3+ ):n(SiO 2 )=9:1; control the solute mass fraction of the reaction system to be 30%; then put 100 mL of mixed active silicic acid, aluminum sulfate, and ferric sulfate solution into a microwave reactor and irradiate it with 600W power for 2 minutes, take it out, and rip...

Embodiment 3

[0026]Embodiment 3: take sodium silicate, ferric sulfate, aluminum sulfate, sulfuric acid and sodium carbonate as main raw materials: first dissolve an appropriate amount of sodium silicate in a certain amount of deionized water, and quickly adjust its pH with concentrated sulfuric acid and sodium carbonate solution To 1.2, stand for activation at room temperature for 30min to obtain activated silicic acid; then add ferric sulfate and aluminum sulfate to the activated silicic acid successively to obtain a mixed solution of activated silicic acid, aluminum sulfate and ferric sulfate, and control the ratio of the amount of substances n (Fe 3+ ):n(Al 3+ )=10:1; n(Fe 3+ ):n(SiO 2 )=10:1; the mass fraction of the solute in the control reaction system is 25%; the pH is adjusted to 1.5 with concentrated sulfuric acid and sodium carbonate solution; then the mixed active silicic acid, aluminum sulfate and ferric sulfate solution are put into the microwave reactor with 800W After radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com