Preparation and Application of Covalent Organic Framework/Titanium Carbide Nanosheet Composite

A technology of covalent organic framework and composite materials, which is applied in the preparation of electrode materials and the preparation of covalent organic framework/Ti3C2 nanosheet composite materials, which can solve problems such as complex process, high safety requirements, and unstable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A covalent organic framework / Ti 3 C 2 The preparation of nanosheet composite material and its application in lithium-sulfur battery adopt the following steps:

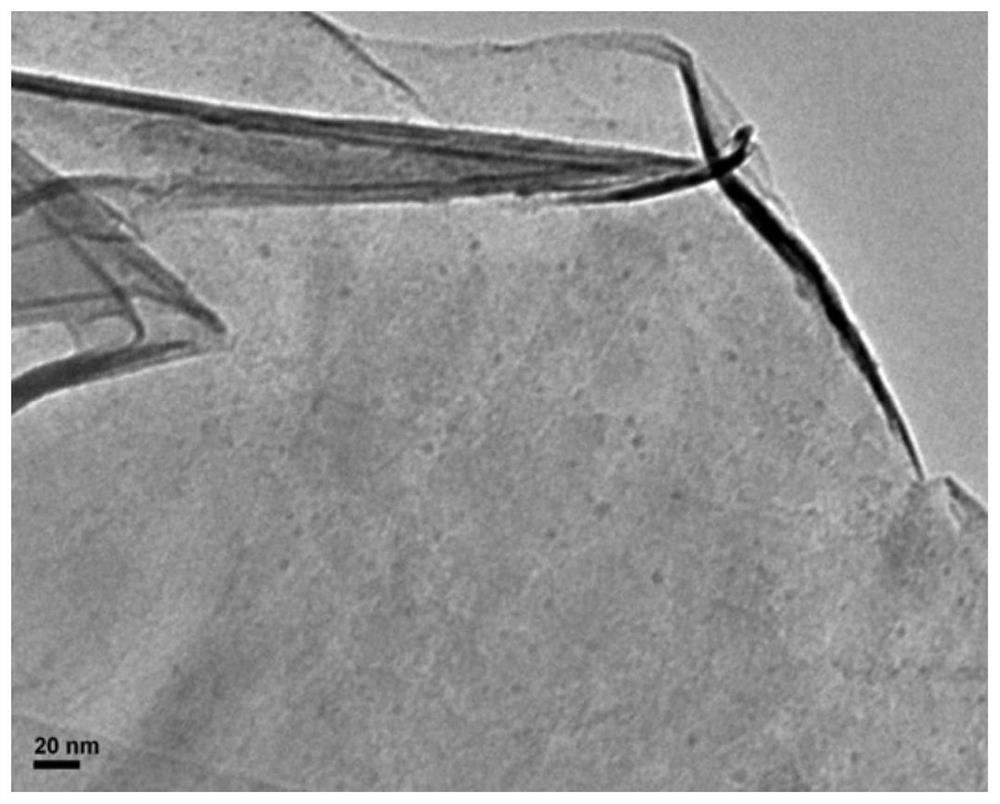

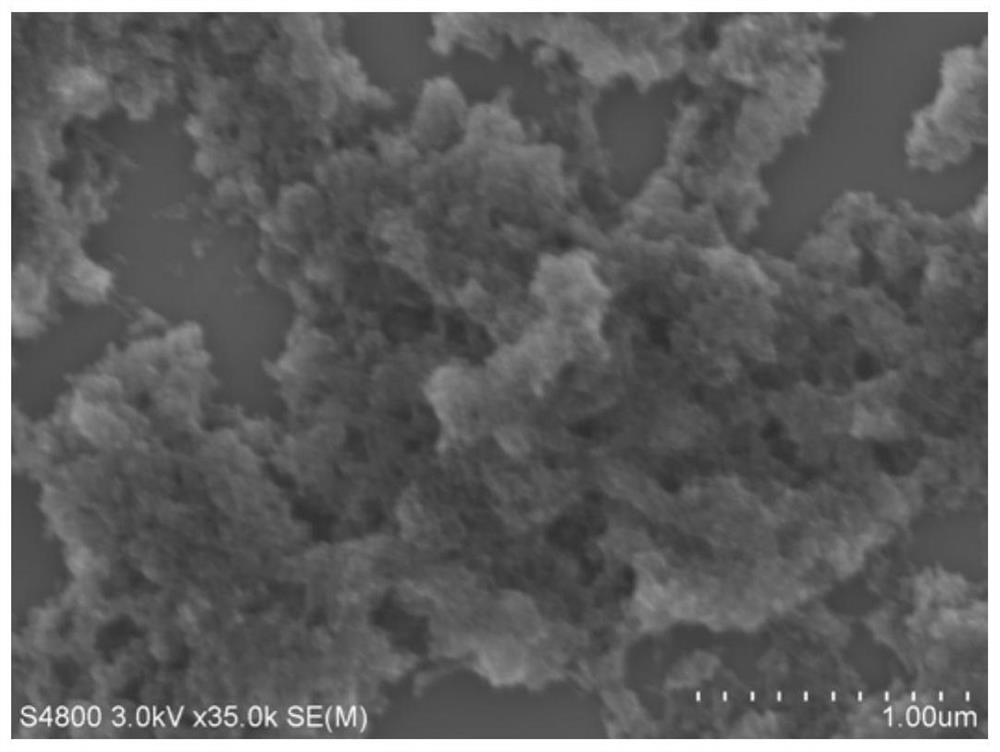

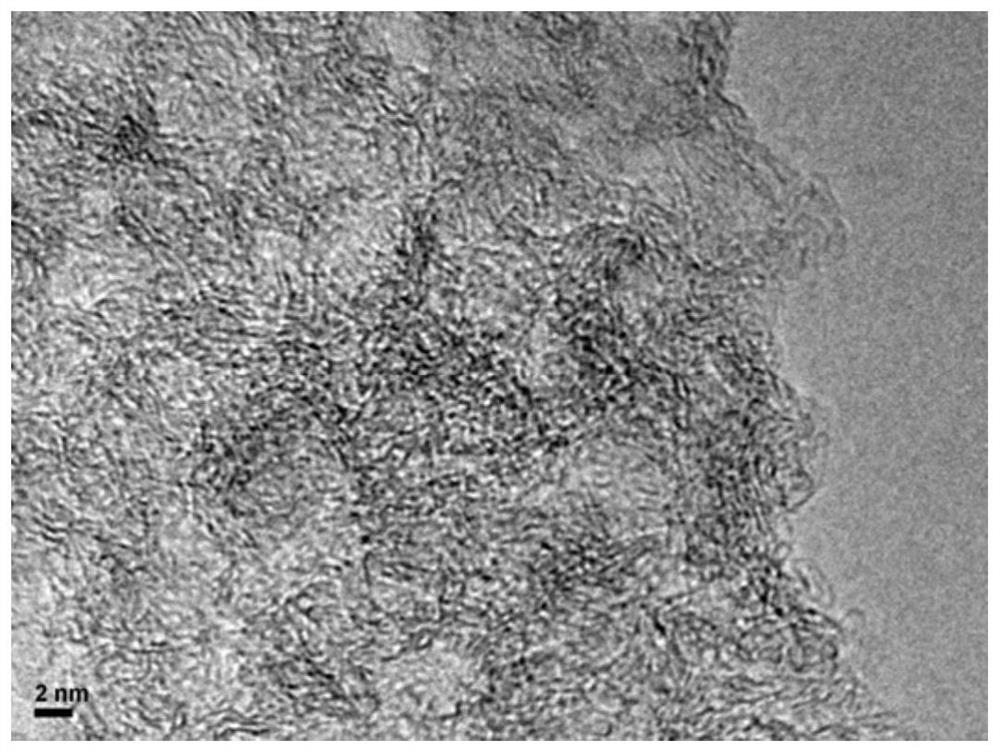

[0027] (1) First use 0.5g LiF and 6mol / L HCl to dissolve Ti 3 AlC 2 (MAX) etch to get Ti 3 C 2 Accordion sample followed by Ti 3 C 2 Ultrasonic in water to obtain single-layer or few-layer Ti 3 C 2 Nanosheets were freeze-dried, and their transmission electron microscope pictures are as follows: figure 1 As shown, the Ti prepared by the present invention 3 C 2 The nanosheets are thin and transparent, indicating fewer layers;

[0028] (2) the solid Ti prepared by step (1) 3 C 2 Nanosheet 200mg, terephthalonitrile 20mg, catalyst ZnCl 2 10mg (the mass ratio of the three is 10:1:0.5) is sealed in a vacuum quartz tube, reacted at a high temperature of 400°C for 10h, and cooled to room temperature after the reaction to obtain a black agglomerated material;

[0029] (3) Stir the black agglomerate materia...

Embodiment 2

[0032] A covalent organic framework / Ti 3 C 2 The preparation of nanosheet composite material and its application in lithium-sulfur battery adopt the following steps:

[0033] (1) First use 0.5g LiF and 6mol / L HCl to dissolve Ti 3 AlC 2 (MAX) etch to get Ti 3 C 2 Accordion sample followed by Ti 3 C 2 Ultrasonic in water to obtain single-layer or few-layer Ti 3 C 2 nanosheets and lyophilize them;

[0034] (2) the solid Ti prepared by step (1) 3 C 2 Nanosheet 20mg, 4,4'-biphenyldinitrile 200mg, catalyst ZnCl 2 200mg (the mass ratio of the three is 1:10:10) is sealed in a vacuum quartz tube, reacted at a high temperature of 700°C for 40h, and cooled to room temperature after the reaction to obtain a black agglomerated material;

[0035] (3) Stir the black agglomerate material prepared in step (2) in water for 10 h, then in dilute hydrochloric acid for 20 h, then alternately filter in tetrahydrofuran and distilled water, and vacuum dry to prepare the covalent organic fr...

Embodiment 3

[0039] A covalent organic framework / Ti 3 C 2 The preparation of nanosheet composite material and its application in lithium-sulfur battery adopt the following steps:

[0040] (1) First use 0.5g LiF and 6mol / L HCl to dissolve Ti 3 AlC 2 (MAX) etch to get Ti 3 C 2 Accordion sample followed by Ti 3 C 2 Ultrasonic in water to obtain single-layer or few-layer Ti 3 C 2 nanosheets and lyophilize them;

[0041] (2) the solid Ti prepared by step (1) 3 C 2 Nanosheet 20mg, Terephthalonitrile 20mg, Catalyst ZnCl 2 200mg (the mass ratio of the three is 1:1:10) is sealed in a vacuum quartz tube, reacted at a high temperature of 400°C for 40h, and cooled to room temperature after the reaction to obtain a black agglomerated material;

[0042] (3) Stir the black agglomerate material prepared in step (2) in water for 24 hours, then in dilute hydrochloric acid for 24 hours, then alternately filter in tetrahydrofuran and distilled water, and vacuum dry to prepare the covalent organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com