A stable and fast response high yield strength bimodal magnetorheological fluid and its preparation method

A technology of magnetorheological fluid and thixotropic agent, applied in magnetic liquids, magnetic objects, magnetic materials, etc., can solve the problems of poor settlement stability, high yield stress, easy settlement and agglomeration, and achieve short response time and high yield. Strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to another aspect of the present invention, the present invention provides a method for preparing a synthetic oil-based compound carrier fluid, comprising: contacting a friction-reducing and anti-wear agent with a synthetic oil to obtain a first suspension; mixing an antioxidant with a second The first suspension is contacted to obtain a second suspension; the thixotropic agent is contacted with the second suspension to obtain a third suspension; the surfactant is contacted with the third suspension to obtain a synthetic oil-based compound carrier liquid.

[0047] According to an embodiment of the present invention, the antifriction and antiwear agent is added to the synthetic oil, and stirred at 40-60 degrees Celsius, preferably at 40-50 degrees Celsius, for 0.5-2 hours to obtain the first suspension.

[0048] According to an embodiment of the present invention, the antioxidant is added to the first suspension, and stirred at 40-60 degrees Celsius, preferably ...

Embodiment 1

[0056] Embodiment 1 provides a high temperature resistant magnetorheological fluid, which is prepared by the following method:

[0057] (1) Add 3.0g (0.5%) molybdenum disulfide (anti-friction and anti-wear agent) to 81g (13.5%) low-viscosity synthetic oil (PAO170), stir at 40°C for 0.5 hours; add 3.0g (0.5% ) organophosphorus compound (antioxidant), stirred and mixed for 1 hour; 6g (1%) organic bentonite (thixotropic agent) was added to the obtained suspension, stirred for 1 hour; then 3.0g (0.5%) alkane Oxythiophosphate (surfactant) was added to the suspension, stirred and mixed at 40° C. for 1 hour to obtain a synthetic oil-based compound carrier fluid.

[0058] (2) 504g (84%) nanometer / micron bimodal carbonyl iron powder (particle diameters are 30nm, 2μm respectively) is added in the ratio of 15:85 to the synthetic oil-based composite carrier liquid, stirred at a high speed of 1000rpm to obtain suspension.

[0059] (3) The above suspension was emulsified at 70° C. for 2 h...

Embodiment 2

[0064] (1) Add 4.2g (0.7%) antifriction and antiwear agent molybdenum disulfide and graphite (1:1) to 45g (7.5%) low-viscosity synthetic oil (PAO168), and stir at 40°C for 0.5 hours; Add 3.0g (0.5%) antioxidant organomolybdenum compound, stir and mix for 1 hour; 6g (1%) thixotropic agent organic bentonite is added in the obtained suspension, stir for 1 hour; then 4.8g (0.8% ) Surfactant alkoxythiophosphate was added to the suspension, stirred and mixed at 40° C. for 1 hour to obtain a synthetic oil-based compound carrier fluid.

[0065] (2) Add 537g (89.5%) nano / micro bimodal carbonyl iron powder (particle diameters are 200nm and 3μm respectively) into the synthetic oil-based composite base fluid at a ratio of 10:90, and stir at a high speed of 1000rpm evenly.

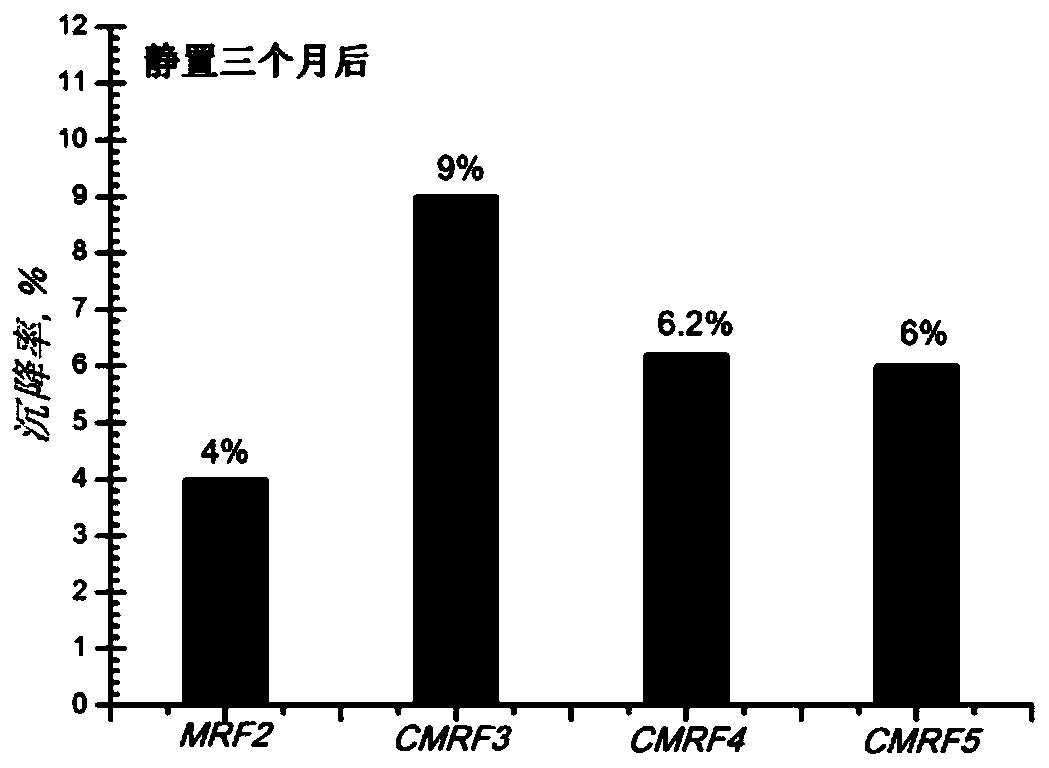

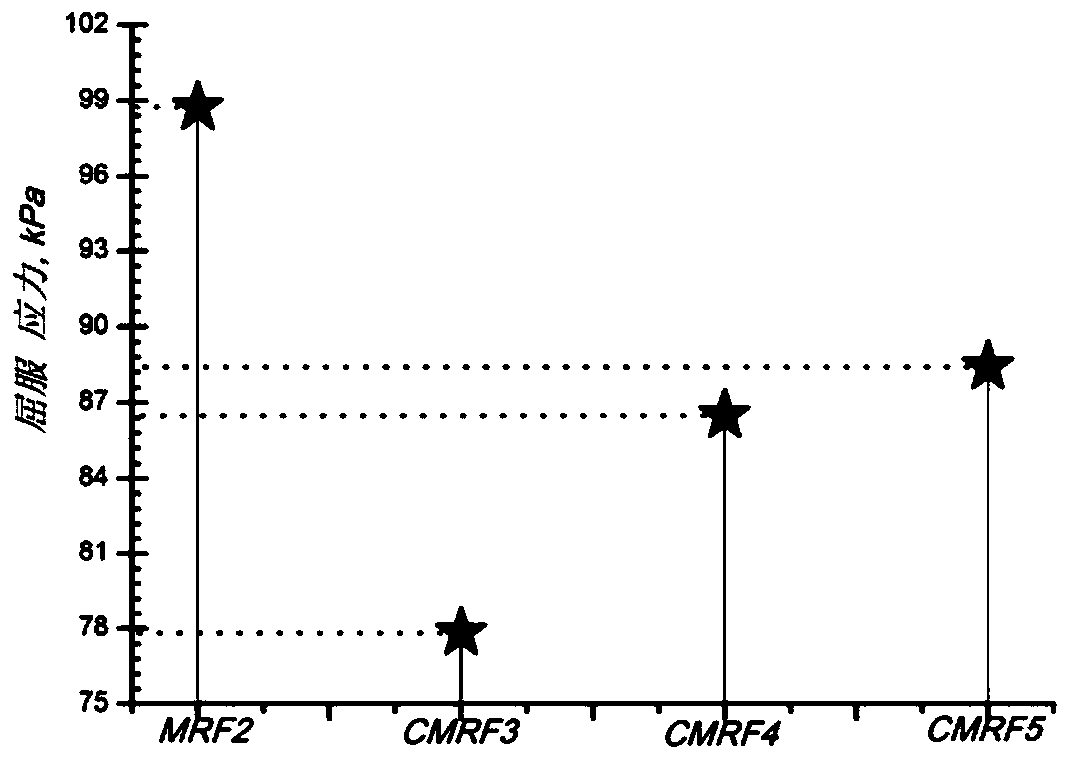

[0066] (3) The above suspension was emulsified at a temperature of 70° C. for 2 hours to prepare a magnetorheological fluid, which was denoted as MRF2.

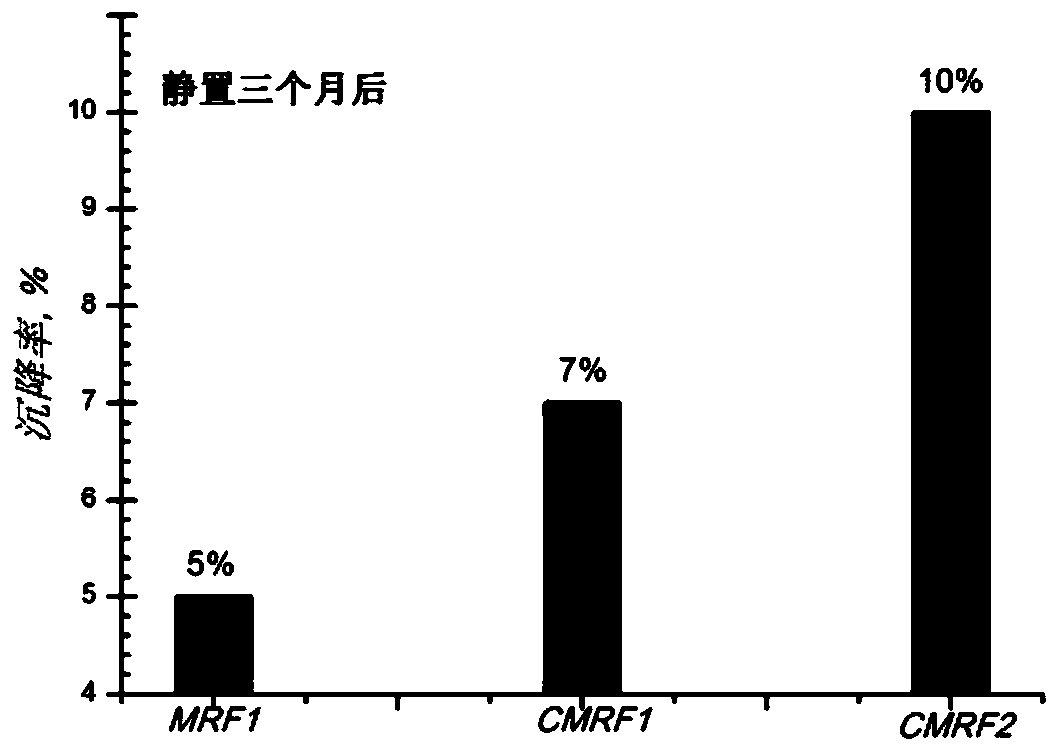

[0067] Put the magnetorheological fluid prepared in this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com