A Method for Longitudinal Connection of the Main Girder at the Continuation of the Bridge Deck of a Steel-Concrete Composite Bridge

A technology of longitudinal connection and steel girders, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of complex structure and aggravated transverse cracking of bridge deck pavement, and achieve simple operation, reduced deformation and deformation of concrete slabs, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

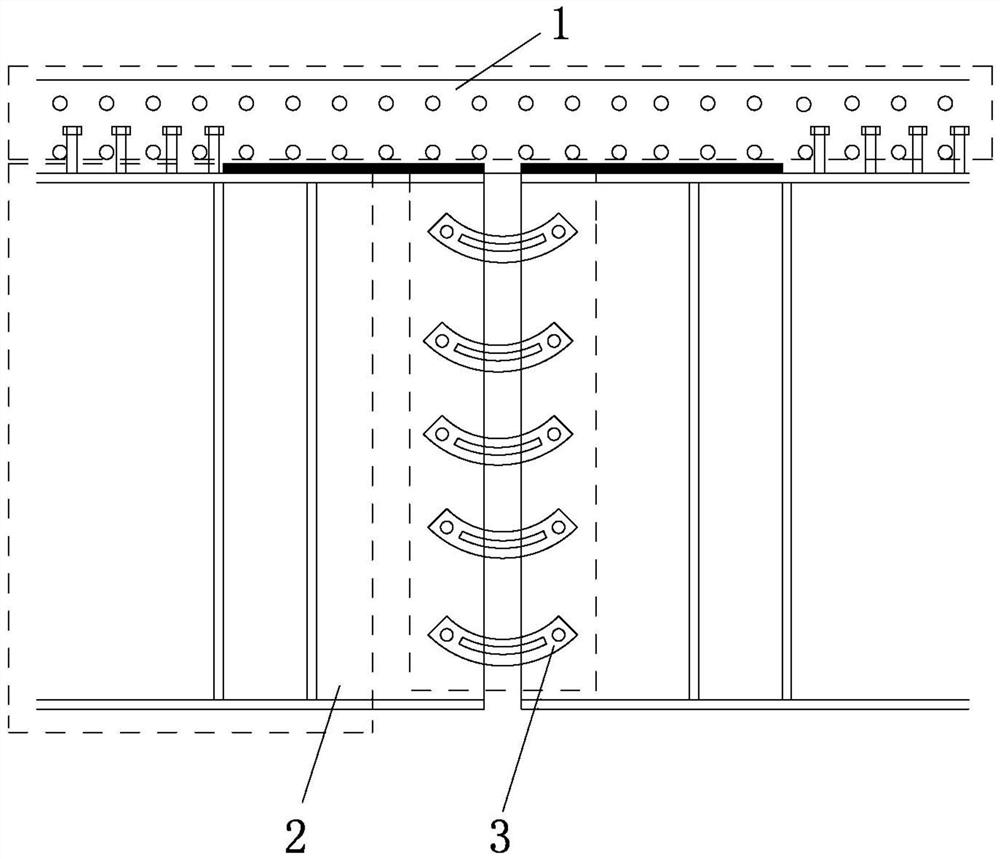

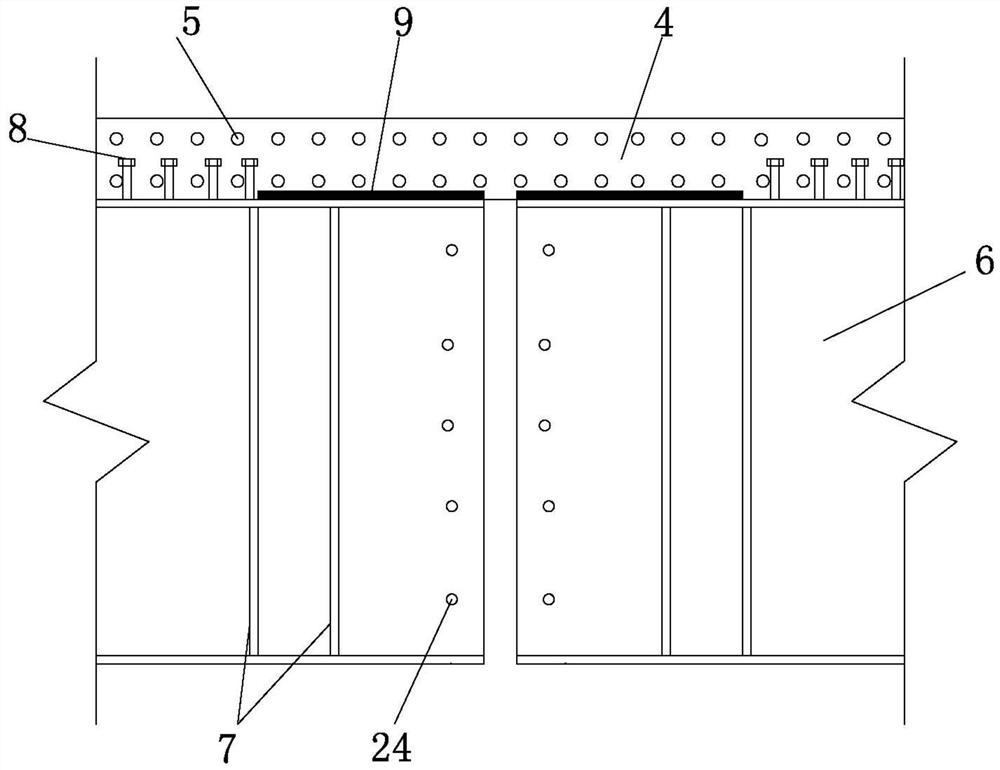

[0026] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a method for longitudinally connecting the main girder at the continuous part of the deck of a steel-concrete composite bridge, comprising the following process steps:

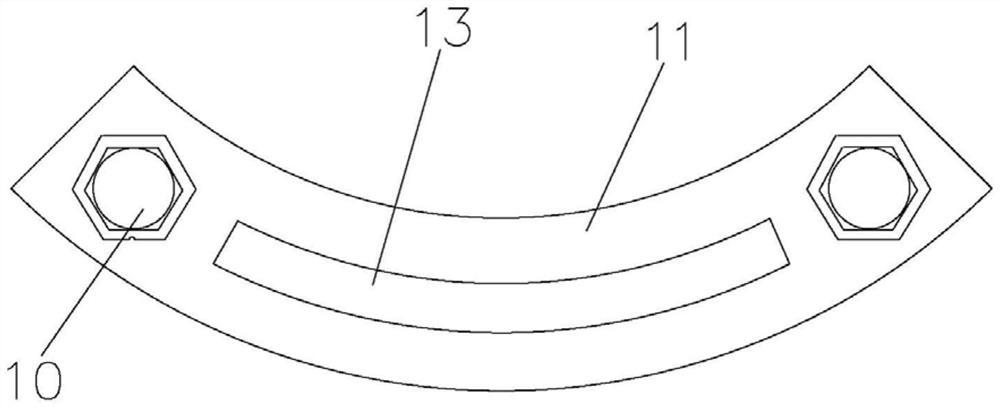

[0027] 1), in the factory, according to the design drawings, the section steel 6, the stiffener 7 and the shear key 8 are welded or bolted according to the design requirements to make the steel girder 2; a reserved bolt hole is set at the corresponding position of the web of the section steel 6, and the For the arrangement of U-shaped steel hinge 3;

[0028] 2), transport the processed steel girder 6 to the construction site, and fix it on the temporary support, then arrange the rubber pad 9 at the end of the steel girder, lay the formwork, pour the concrete bridge deck 1, and perform maintenance. After the strength of bridge deck 1 meets the specification requirements, remove the formwork;

[0029] 3), use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com