Light fully assembled large cantilever ultra-high performance concrete wing beam and its construction method

An ultra-high-performance, fully-assembled technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as high requirements for transportation equipment and lifting equipment, difficulties in transportation and installation of prefabricated components, and greater impact on the surrounding environment , to achieve the effect of convenient assembly process, convenient and fast construction, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

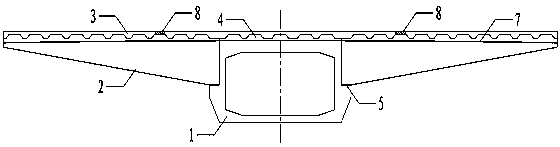

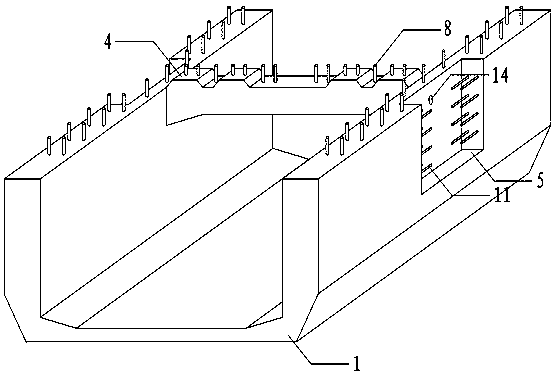

[0037] refer to Figure 1~10 : Light fully assembled large cantilever ultra-high performance concrete wing beam, including trough beam 1, tooth-shaped variable-section cantilever beam 2 and wave-rib bridge deck 3, the trough-shaped beam 1, tooth-shaped variable-section cantilever beam 2 and wave-rib bridge The panel 3 is an ultra-high performance concrete (UHPC) prefabricated component. The top outer surface of the web of the channel beam 1 is provided with a splicing groove 5 connected to the tooth-shaped variable-section cantilever beam 2. There is a transverse beam 4 on the side; the top of the transverse beam 4 is tooth-shaped, and the anchor bolts 8 for splicing with the bridge deck are embedded in advance; The anchor bolts 8 spliced with the bridge deck; the wave-rib bridge deck 3 is assembled from several prefabricated bridge decks, and the wave-shaped ribs at the bottom match the teeth on the top of the groove-shaped beam 1 and the tooth-shaped variable-section canti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com