A kind of active cathode and its preparation method and application

An active cathode and cathode technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of high price, poor activity, poor stability, stable structure and performance, and achieve low cost, good stability, and prevent electrode turtles. cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

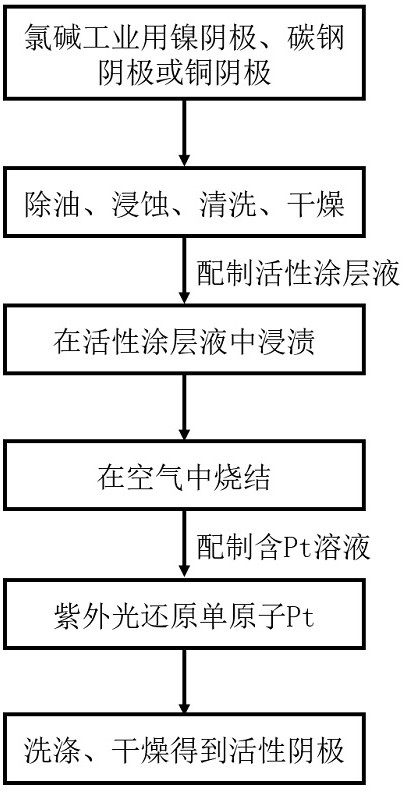

[0041] 1) if figure 1 Shown is a flowchart of the manufacturing method of the active cathode of the present invention. A nickel mesh with a size of 10 × 30 mm was cut, placed in acetone for 30 min and ultrasonically treated to remove the oil on the surface, and then rinsed with ultrapure water. The rinsed nickel mesh was etched in 20% (weight) boiling hydrochloric acid for 5 min.

[0042] 2) Rinse with a large amount of ultrapure water, and dry in a vacuum oven for later use.

[0043] 3) Prepare the active coating solution, the formula is as follows:

[0044] Ruthenium trichloride 100-200 g / L

[0045] Hydrochloric acid 20g / L

[0046] Take 100 mL of the prepared active coating solution and place it in a beaker, immerse the pretreated nickel mesh substrate in the active coating solution for 30 min, and then slowly lift it out of the beaker. Then, the nickel mesh with the active coating solution attached was placed in a vacuum oven and dried at 80 °C for 2 h.

[0047] 4) Th...

Embodiment 2

[0054] 1) Cut out a nickel mesh with a size of 10×30 mm, place it in acetone for 30 min and ultrasonically treat it to remove the oil on the surface, and then rinse it with ultrapure water. Place the rinsed nickel mesh in 20% (weight) boiling hydrochloric acid for 5 minutes.

[0055] 2) Rinse with a large amount of ultrapure water, and dry in a vacuum oven for later use.

[0056] 3) Prepare the active coating solution, the formula is as follows:

[0057] Ruthenium trichloride 100 g / L

[0058] Cerium chloride 20-50 g / L

[0059] Hydrochloric acid 20g / L

[0060] Take 100 mL of the prepared active coating solution and place it in a beaker, immerse the pretreated nickel mesh substrate in the active coating solution for 30 min, and then slowly lift it out of the beaker. Then, the nickel mesh with the active coating solution attached was placed in a vacuum oven and dried at 80 °C for 2 h.

[0061] 4) The above dried nickel mesh was put into a muffle furnace for sintering, the ho...

Embodiment 3

[0067] 1) Cut out a nickel mesh with a size of 10×30 mm, place it in acetone for 30 min and ultrasonically treat it to remove the oil on the surface, and then rinse it with ultrapure water. Place the rinsed nickel mesh in 20% (weight) boiling hydrochloric acid for 5 minutes.

[0068] 2) Then rinse with a large amount of ultrapure water, and dry in a vacuum oven for later use.

[0069] 3) Prepare the active coating solution, the formula is as follows:

[0070] Ruthenium trichloride 100 g / L

[0071] Cerium chloride 20-50 g / L

[0072] Hydrochloric acid 20g / L

[0073] Take 100 mL of the prepared active coating solution and place it in a beaker, immerse the pretreated nickel mesh substrate in the active coating solution for 30 min, and then slowly lift it out of the beaker. Then, the nickel mesh with the active coating solution attached was placed in a vacuum oven and dried at 80 °C for 2 h.

[0074] 4) The above dried nickel mesh was put into a muffle furnace for sintering, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com