A method for purifying lithium element from battery powder

A battery and element technology, applied in the field of waste battery recycling and treatment, can solve the problem of metal element loss and achieve strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

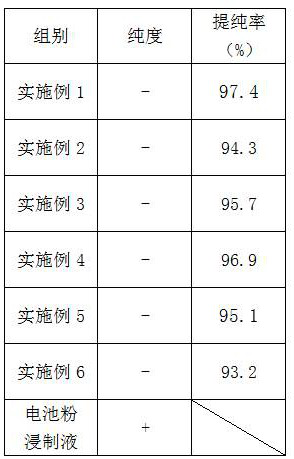

Examples

Embodiment 1

[0022] (1) Preparation of extract

[0023] The extracting liquid is formed by mixing saponified extractant and saponified kerosene, and the volume ratio of saponified extractant and saponified kerosene is 43:57.

[0024] The saponified extractant is prepared by the following method: add 2 g of sodium hydroxide to 40 ml of the extractant, add absolute ethanol after stirring, heat at 50° C. for 1.5 h, evaporate the ethanol to obtain the saponified extractant.

[0025] Saponified kerosene is prepared by the following method: add 4 g of sodium hydroxide to 50 ml of kerosene, add absolute ethanol after stirring, heat at 50° C. for 2 hours, and evaporate the ethanol to obtain saponified kerosene.

[0026] (2) Purification method:

[0027] S1. The battery powder and 0.7M sulfuric acid are mixed with a liquid-solid ratio of 50ml:10g and filtered; the battery powder infusion solution is obtained;

[0028] S2. After mixing and shaking 4ml of the battery powder infusion solution and 30...

Embodiment 2

[0031] (1) Preparation of extract

[0032] The extracting liquid is prepared by mixing saponified extractant and saponified kerosene, and the volume ratio of saponified extractant and saponified kerosene is 30:70.

[0033] The saponified extractant is prepared by the following method: add 1 g of sodium hydroxide to 40 ml of the extractant, add absolute ethanol after stirring, heat at 60° C. for 1 h, evaporate the ethanol to obtain the saponified extractant.

[0034] Saponified kerosene is prepared by the following method: add 3 g of sodium hydroxide to 30 ml of kerosene, add absolute ethanol after stirring, heat at 40° C. for 2 hours, and evaporate the ethanol to obtain saponified kerosene.

[0035] (2) Purification method:

[0036] S1. The battery powder and 0.6 M sulfuric acid are mixed with a liquid-solid ratio of 50ml: 5g and filtered; the battery powder infusion solution is obtained;

[0037] S2. After mixing and shaking 4ml of the battery powder infusion solution and 2...

Embodiment 3

[0040] (1) Preparation of extract

[0041] The extracting solution is formed by mixing saponified extractant and saponified kerosene, and the volume ratio of the saponified extractant and saponified kerosene is 50:50.

[0042] The saponified extractant is prepared by the following method: add 2 g of sodium hydroxide to 50 ml of the extractant, add absolute ethanol after stirring, heat at 70° C. for 2 h, evaporate the ethanol to obtain the saponified extractant.

[0043] Saponified kerosene is prepared by the following method: add 7 g of sodium hydroxide to 55 ml of kerosene, add absolute ethanol after stirring, heat at 70° C. for 3 hours, and evaporate the ethanol to obtain saponified kerosene.

[0044] (2) Purification method:

[0045] S1. The battery powder and 0.8 M sulfuric acid are mixed with a liquid-solid ratio of 50ml:10g and filtered; the battery powder infusion solution is obtained;

[0046] S2. After mixing and shaking 4ml of the battery powder infusion solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com