A kind of high-reflectivity acrylic heat-shielding paint and preparation method thereof

A high-reflectivity, acrylic technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve problems such as room temperature rise, unsatisfactory cooling effect, poor heat insulation performance of coatings, etc., and achieve excellent reflection performance and excellent covering ability , the effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

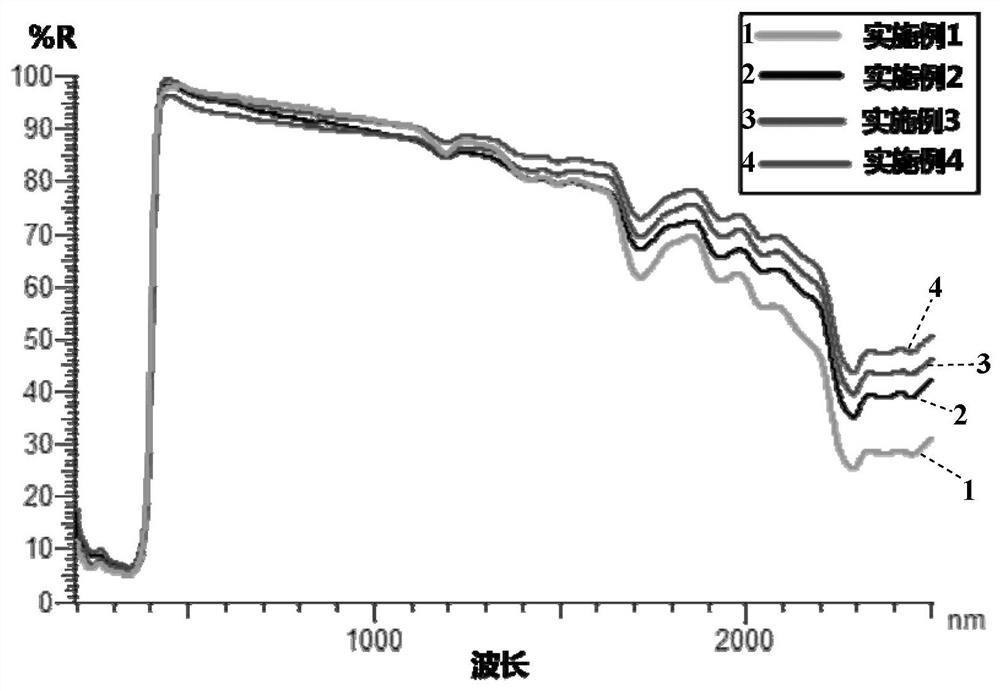

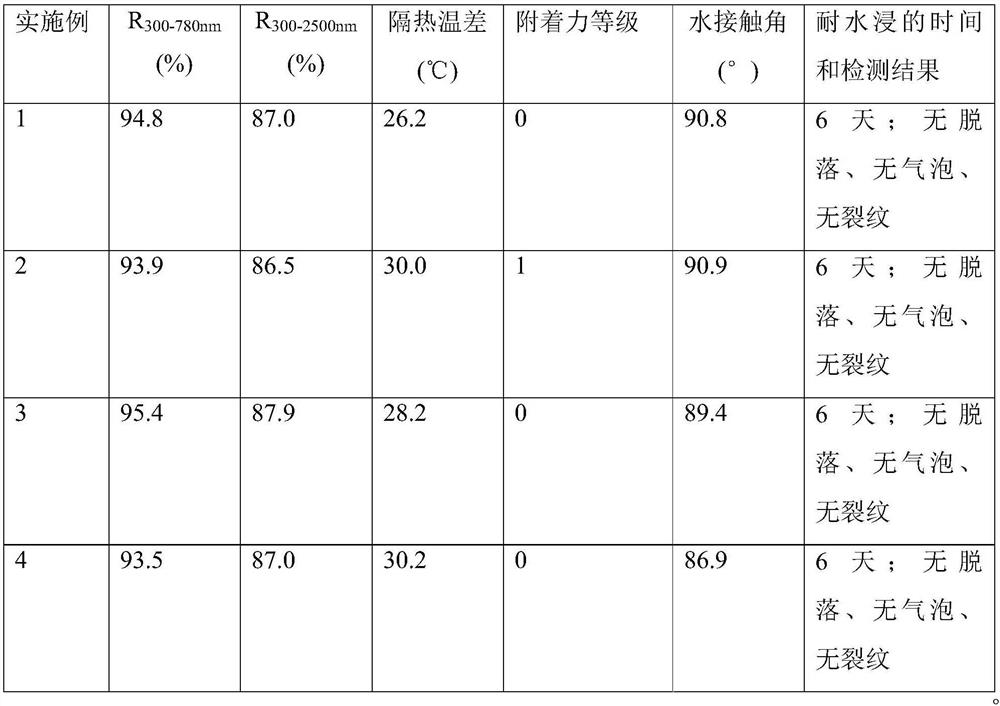

Examples

Embodiment 1

[0044] Proportion by mass percentage: Hydroxy acrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 44%, R-803 titanium dioxide (particle size range 200-900nm) is 26%, modified aluminum powder (surface coating Flake aluminum powder covered with titanium dioxide) is 9%, xylene is 8%, butyl acetate is 5%, high boiling point solvent DBE (divalent ester) is 1%, 245 leveling agent is 0.5%, BYK- 065 defoamer is 0.5%, 202P anti-sedimentation agent is 1wt%, and hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) are 5%;

[0045] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder. Stir hydroxyacrylic resin, solvent, and various additives at a med...

Embodiment 2

[0047] Proportion according to mass percentage: hydroxyacrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 46%, titanium dioxide titanium dioxide (particle size range 200 ~ 900nm, Yunnan Xinli, R-803) is 23%, Hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) 5%, modified aluminum powder (flaky aluminum powder coated with titanium dioxide on the surface) 9%, xylene 7.5%, acetic acid Butyl ester is 4.5%, high boiling point solvent DBE is 0.9%, BYK-161 dispersant is 2%, 245 leveling agent is 0.44%, BYK-065 defoamer is 0.66%, 202P anti-settling agent is 1%;

[0048] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder; the hydroxyacrylic ac...

Embodiment 3

[0050] Proportion by mass percentage: Hydroxy acrylic resin (Taichang Resin Co., Ltd., 7119-X-50) is 46%, titanium dioxide (particle size range 200-900nm, Yunnan Xinli, R-803) is 23%, modified Aluminum powder (flake aluminum powder coated with titanium dioxide on the surface) is 9%, xylene is 7.7%, hollow glass microspheres (particle size range 10-30 μm, Shanghai Zhenxu Chemical Co., Ltd.) is 4%, butyl acetate 5% for high boiling point solvent DBE, 2.3% for BYK-161 dispersant, 0.5% for 245 leveling agent, 0.5% for BYK-065 defoamer, 1% for 202P anti-settling agent;

[0051] Preparation method: Add 6g of flake aluminum powder (particle size range 8-15μm) into 200ml of absolute ethanol for ultrasonic dispersion, and stir at 60°C for 30min, add 20ml of butyl titanate, continue to stir for 6h, and stand still to obtain white gray The precipitate was centrifugally filtered and dried at 100°C to obtain modified aluminum powder; the hydroxyacrylic acid emulsion, solvent, and various a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com