Environmental-friendly inorganic coating and preparation method thereof

An inorganic coating, environmental protection technology, applied in fireproof coatings, antifouling/underwater coatings, alkali metal silicate coatings, etc., can solve the problems of poor acid and alkali water resistance, poor adhesion, environmental pollution, etc., to increase adsorption The ability of formaldehyde, excellent high temperature resistance, the effect of increasing the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

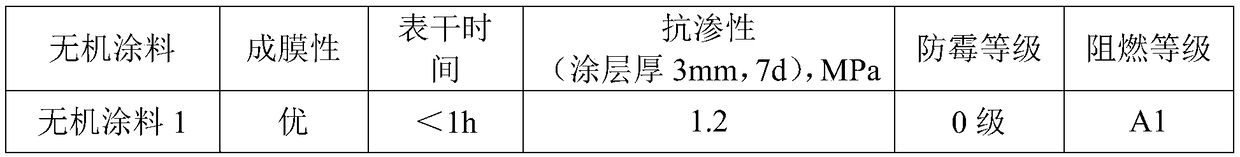

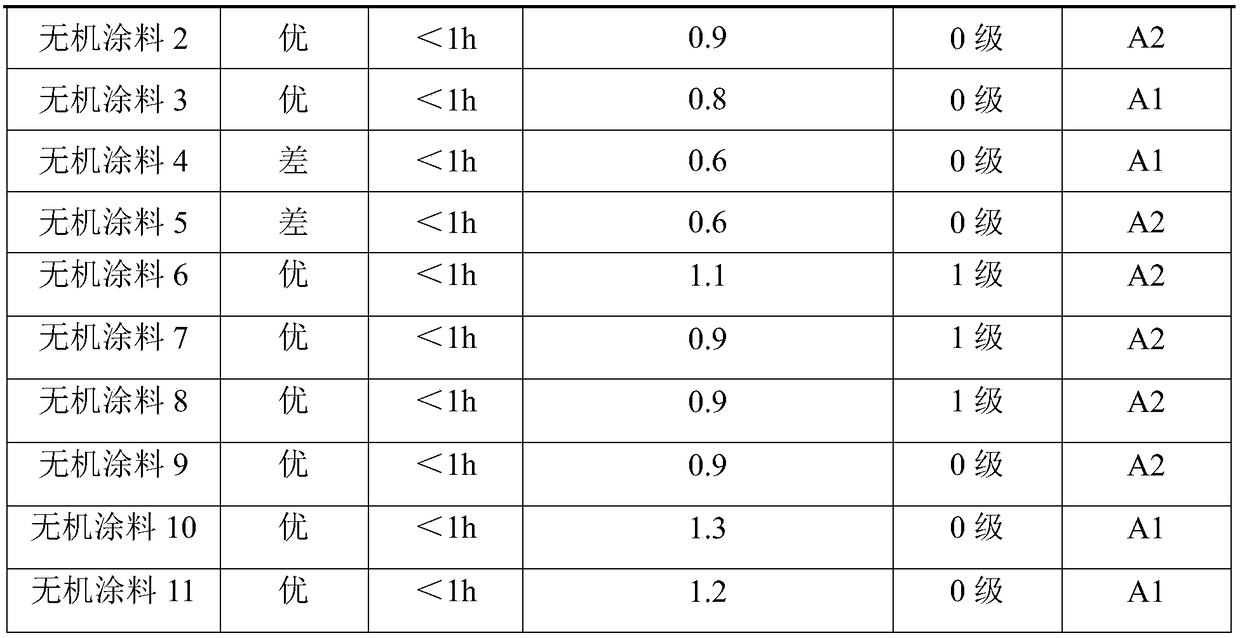

Embodiment 1

[0024] A kind of environment-friendly inorganic paint provided by the present embodiment comprises the following steps:

[0025] (1) Get the following raw materials in parts by weight: 45 parts of potassium silicate, 10 parts of kaolin, 10 parts of talcum powder, 5 parts of sericite, 1.3 parts of silicon dioxide (average particle size is 120nm), modified shell 7.8 parts of powder, 0.14 parts of cellulose, 0.15 parts of polysiloxane solution, 0.4 parts of low molecular weight unsaturated polycarboxylic acid polymer solution, 7 parts of pigment, 5 parts of pure acrylic emulsion, 14 parts of deionized water;

[0026] (2) According to the formulation amount of step (1), add water, cellulose, dispersant, and 50% defoamer in the dispersion tank successively in the formulation amount, and stir under the condition of 1200r / min at a rotating speed The mixed solution was obtained in 20 minutes, and silicon dioxide, modified shell powder, pigments and fillers were added to the resulting ...

Embodiment 2

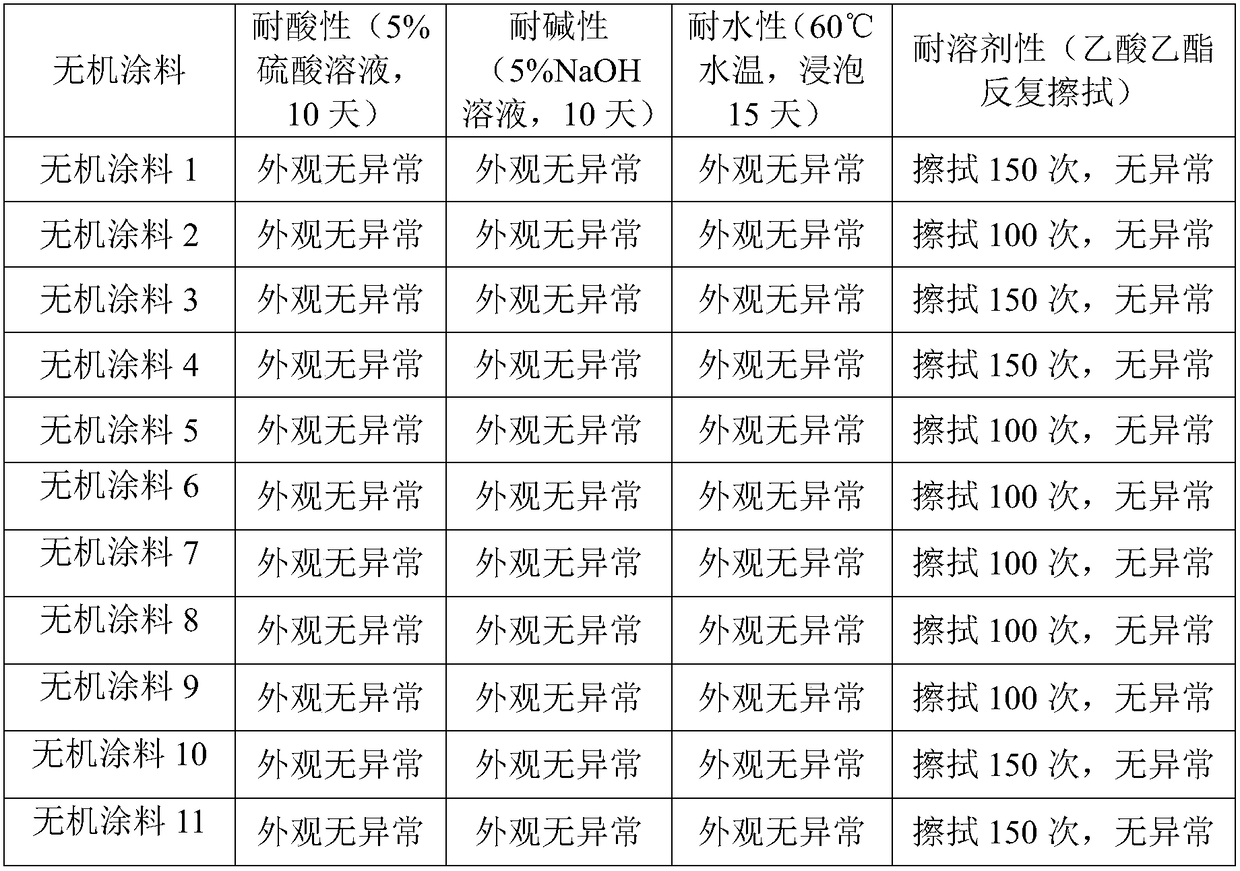

[0028] The difference from Example 1 is that "45 parts of potassium silicate" in step (1) of Example 1 is replaced with "30 parts of potassium silicate", "40 parts of potassium silicate", "50 parts of potassium silicate ", "60 parts of potassium silicate", prepared inorganic coating 2, inorganic coating 3, inorganic coating 4, inorganic coating 5.

Embodiment 3

[0030] The difference with Example 1 is: "10 parts of kaolin, 10 parts of talcum powder, 5 parts of sericite," in the step (1) of embodiment 1 are replaced with "30 parts of kaolin", "30 parts of talcum powder", "30 parts of sericite", prepared inorganic coating 6, inorganic coating 7, inorganic coating 8, and inorganic coating 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com