High temperature-resisting and anti-fatigue dynamic absorber material and preparation method thereof

A dynamic vibration absorber and anti-fatigue technology, which is applied in the field of dynamic vibration absorber materials, can solve problems such as product vibration absorption failure, failure to meet precision requirements, performance attenuation, etc., and achieve reliable vibration absorption performance, excellent fatigue resistance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A dynamic shock absorber material with high temperature resistance and fatigue resistance. The raw materials for its production include: 60 parts of methyl vinyl silicone rubber, 30 parts of silicon dioxide, 3 parts of coloring pigment, 3 parts of heat stabilizer, and 4 parts of structural control agent , 3 parts of compatibilizer, 0.7 parts of vulcanizing agent.

Embodiment 2

[0030] A high-temperature-resistant and fatigue-resistant dynamic vibration absorber material, its production raw materials include: 80 parts of methyl vinyl silicone rubber, 10 parts of silicon dioxide, 5 parts of coloring pigment, 1 part of heat stabilizer, and 5 parts of structural control agent , 2 parts of compatibilizer, 1 part of vulcanizing agent.

Embodiment 3

[0032] A dynamic shock absorber material with high temperature resistance and fatigue resistance. The raw materials for its production include: 60 parts of methyl vinyl silicone rubber, 30 parts of silicon dioxide, 3 parts of coloring pigment, 3 parts of heat stabilizer, and 4 parts of structural control agent , 3 parts of compatibilizer, 0.7 parts of vulcanizing agent.

[0033] The preparation of described dynamic vibration absorber material:

[0034] S1. Weigh each raw material according to the preset value, put the raw materials into the internal mixer, set the mixing temperature to 40°C, and the mixing pressure to 140kgf / cm 2 , mixed for 30min to obtain rubber compound;

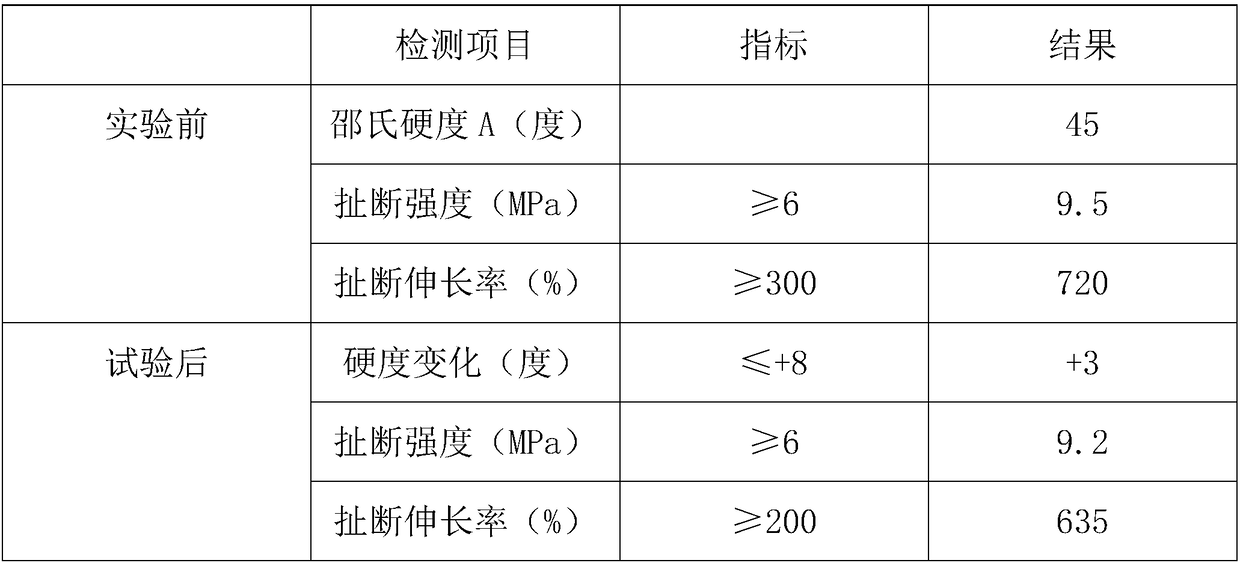

[0035] S2. Detect the hardness, strength and elongation of the rubber compound, select a rubber compound with a hardness of 55-65ShA, a strength of not less than 7MPa, and an elongation rate of not less than 300%, and record it as rubber compound A;

[0036] S3. Send the rubber material A into the open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com