Metal-plant polyphenol complex crystal material and preparation method

A technology of plant polyphenols and crystal materials, applied in the field of advanced materials, can solve the problems of amorphous framework, irregular shape, difficult to effectively control the assembly process of plant polyphenols and metal ions, etc., to achieve easy-to-obtain sources and simple synthesis steps , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the metal-plant polyphenol complex crystal disclosed by the invention comprises the following steps:

[0032] (1) Dissolve the polyether block copolymer (such as F127) in a certain volume of water / alcohol mixed solvent, then add a certain amount of alkali (such as ammonia water), stir well and then add polyphenol compound, until the polyphenol is completely After dissolution to obtain a clear solution, stirring was continued at room temperature for a period of time (2-24 hours).

[0033] (2) Add a certain amount of metal ion solution (such as copper nitrate aqueous solution) to the above solution, continue to stir for 2 to 24 hours, transfer the product to a hydrothermal kettle for 12 to 24 hours, and the hydrothermal temperature is 50-130 ℃. Then the product is collected by centrifugation and dried to obtain metal-plant polyphenol complex crystals.

Embodiment 1

[0035] (1) Dissolve 0.20g block copolymer F127 in 37mL H 2 O and 8 mL of absolute ethanol, after stirring evenly, add 0.4 mL of ammonia water, and continue stirring for about 1 h. Then add 0.20g of tannic acid and stir for 24 hours after the dissolution is complete.

[0036] (2) Add 2 mL of freshly prepared metal ion solution to the above solution, and continue stirring for 24 h. The solution containing metal ions was freshly prepared Cu(NO 3 ) 2 solution, Zn(NO 3 ) 2 , Ni(NO 3 ) 2 or Co(NO 3 ) 2 solution, please refer to Table 1 for the specific dosage:

[0037] Table 1. Preparation of fusiform metal-plant polyphenol complex crystals

[0038]

[0039] (3) The above product was transferred to a 100mL reactor, placed in an oven and heated at 100°C for 24 hours, and then centrifuged to collect the hydrothermal product to obtain the crystals of the fusiform metal-plant polyphenol complex.

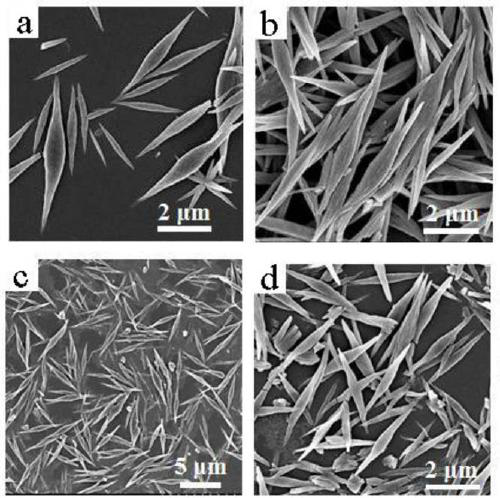

[0040] The results of the corresponding products in Table 1 are shown in fi...

Embodiment 2

[0042] (1) Dissolve 0.20g block copolymer F127 in 37mL H 2 O and 8mL of absolute ethanol, after stirring evenly, add 0.3-0.8mL of ammonia water, and continue stirring for about 1h. Then add 0.20g of tannic acid and stir for 24 hours after the dissolution is complete.

[0043] (2) Add 2 mL of freshly prepared metal ion solution to the above solution, and continue stirring for 24 h. The metal ion solution was freshly prepared Cu(NO 3 ) 2 . Please refer to Table 2 for the specific dosage:

[0044] Table 2. Preparation of metal-plant polyphenol complex crystals with different morphologies

[0045] metal precursor

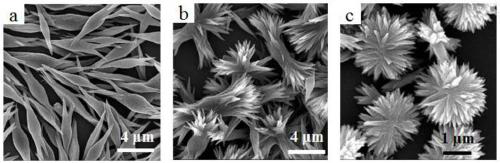

[0046] (3) The above product was transferred to a 100mL reactor, placed in an oven and heated at 100°C for 24 hours, and then the hydrothermal product was collected by centrifugation to obtain metal-plant polyphenol complex crystals with different shapes. The results of the corresponding products in Table 2 are shown in image 3 shown in each figure. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com