Method for refining cefonicid dibenzyl ethylenediamine salts

A technology of cefnixime dibenzylethylenediamine salt and cefdonizil salt, which is applied in the field of refining cefnixime intermediates, can solve the problem that cannot be used in the preparation of cefnixime sodium powder for injection, cefnixime sodium Benzyl ethylenediamine salt has deep color grade and unqualified quality of cefanixime sodium finished product, so as to achieve the effect of easy control of the production process, no by-product formation, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method comprises the following steps:

[0031] A. Resin ion exchange: first add cation exchange resin to the lysate, then add the crude product of cefanisil salt, stir at 0-20°C until the crude product of cefanisil salt is completely dissolved, and filter out the resin after stirring for 2-6 hours. Then the aqueous phase is separated from the organic phase, and the aqueous phase is retained for decolorization treatment, and the filtered resin is soaked and washed with water 0.5 to 2 times the quality of the crude product of cefonixime salt to obtain lotion A;

[0032] The cation exchange resin is any one of Amberlyst 15, Amberlite IR-120, Duolite ES-280, Themax T-63 or Themax T-54, and the mass ratio of the cation exchange resin to the crude product of cefanixime salt is 2 to 5 :1;

[0033] Described eluent is the mixing of water and organic solvent A, and organic solvent A is the mixing of any one or several in methylene dichloride, ethyl acetate, carb...

Embodiment 1

[0043] A kind of refining method of cefanixime dibenzylethylenediamine salt, the crude product of cefanixime dibenzylethylenediamine salt is ion-exchanged with a resin and decolorized with a decolorizing agent, and then undergoes a salt-forming reaction with a transamination agent, After crystallization with a precipitating agent, the refined cefanisidine dibenzylethylenediamine salt is obtained.

[0044] The preparation method comprises the following steps:

[0045] A. Resin ion exchange: Add 10ml of ethyl acetate and 60ml of purified water into the reaction tank, then add 40g of Amberlyst 15 macroporous cation exchange resin, control the temperature at 0°C and stir, add 20g of cefanixime dibenzylethylenediamine salt For the crude product, stir at 0°C until the crude product of cefanixime dibenzylethylenediamine salt is completely dissolved; after stirring for 2 hours, filter out the resin, statically separate the phases, keep the lower aqueous phase for decolorization treatm...

Embodiment 2~5

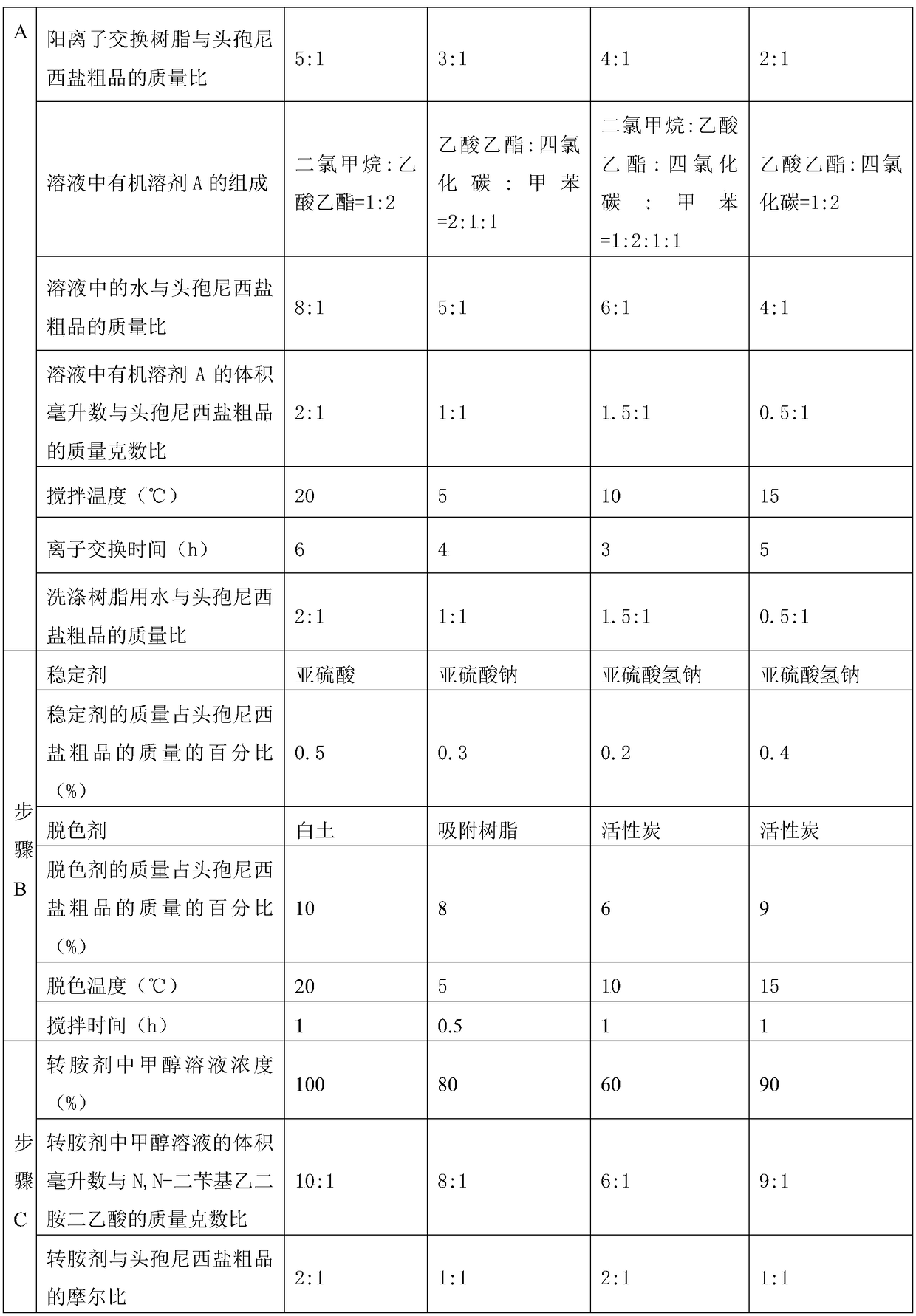

[0049] Embodiments 2-5 are the same as the process steps in embodiment 1, the difference is the selection of process parameters, as shown in Table 1 below.

[0050] Table 1

[0051]

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com