Anti-volatilization structure applicable to chemical liquid raw material barrel

A technology for chemical liquids and raw material barrels, applied in the direction of locking equipment, closing, packaging, etc., can solve the problems of splashing, quality degradation, leakage of filling tubes inserted into the bottle mouth, etc., to achieve the effect of convenient transportation and less contact with air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

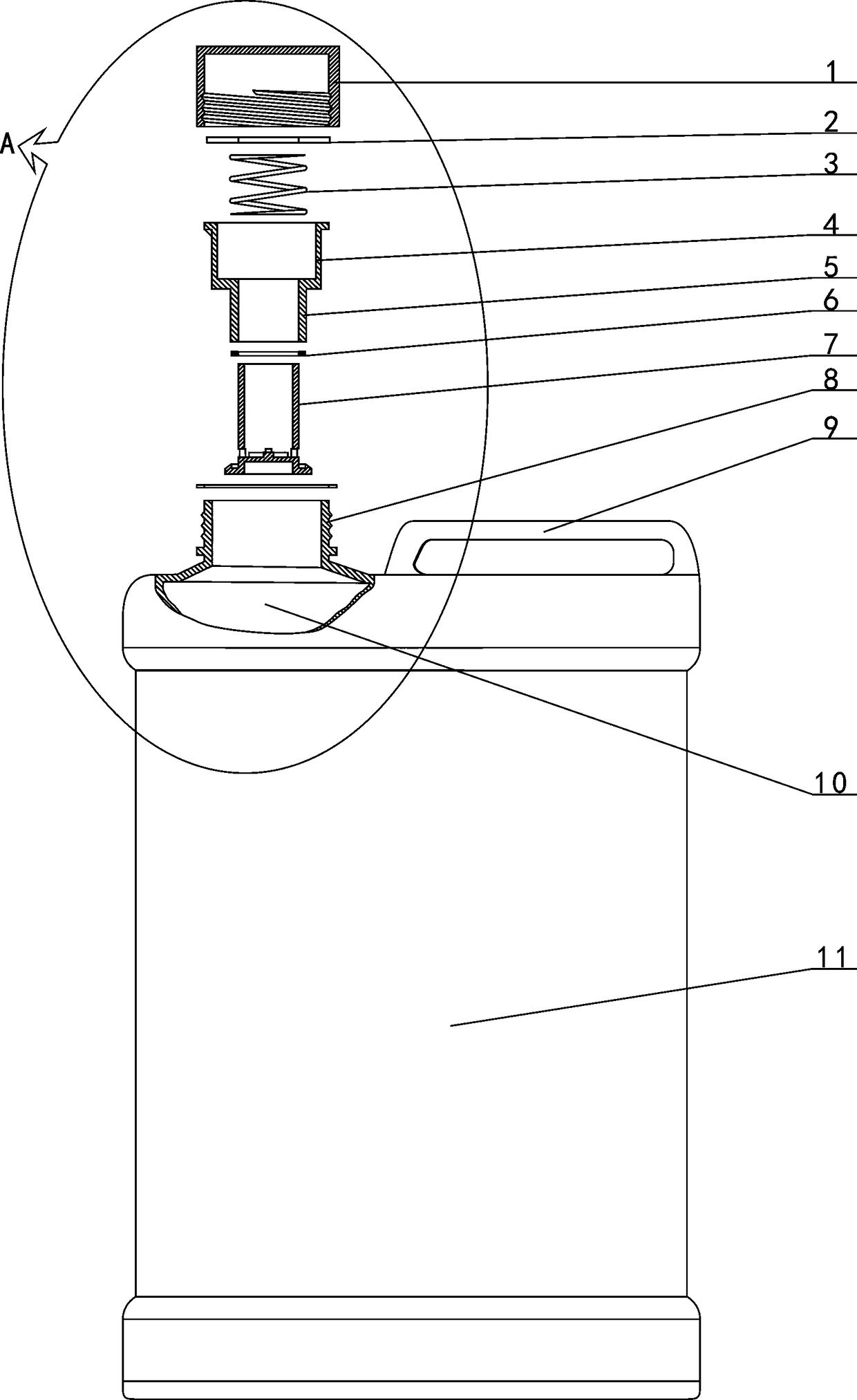

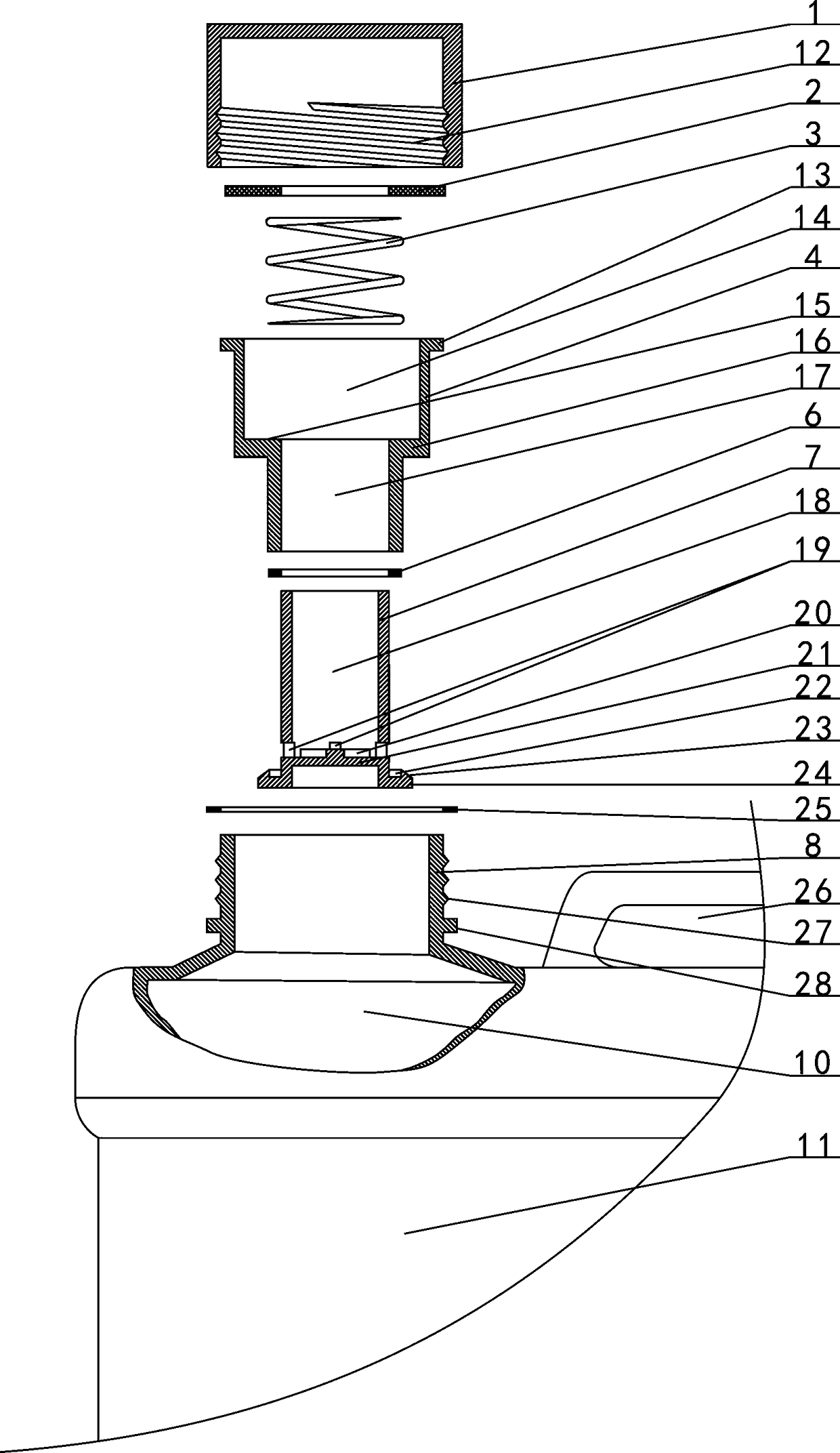

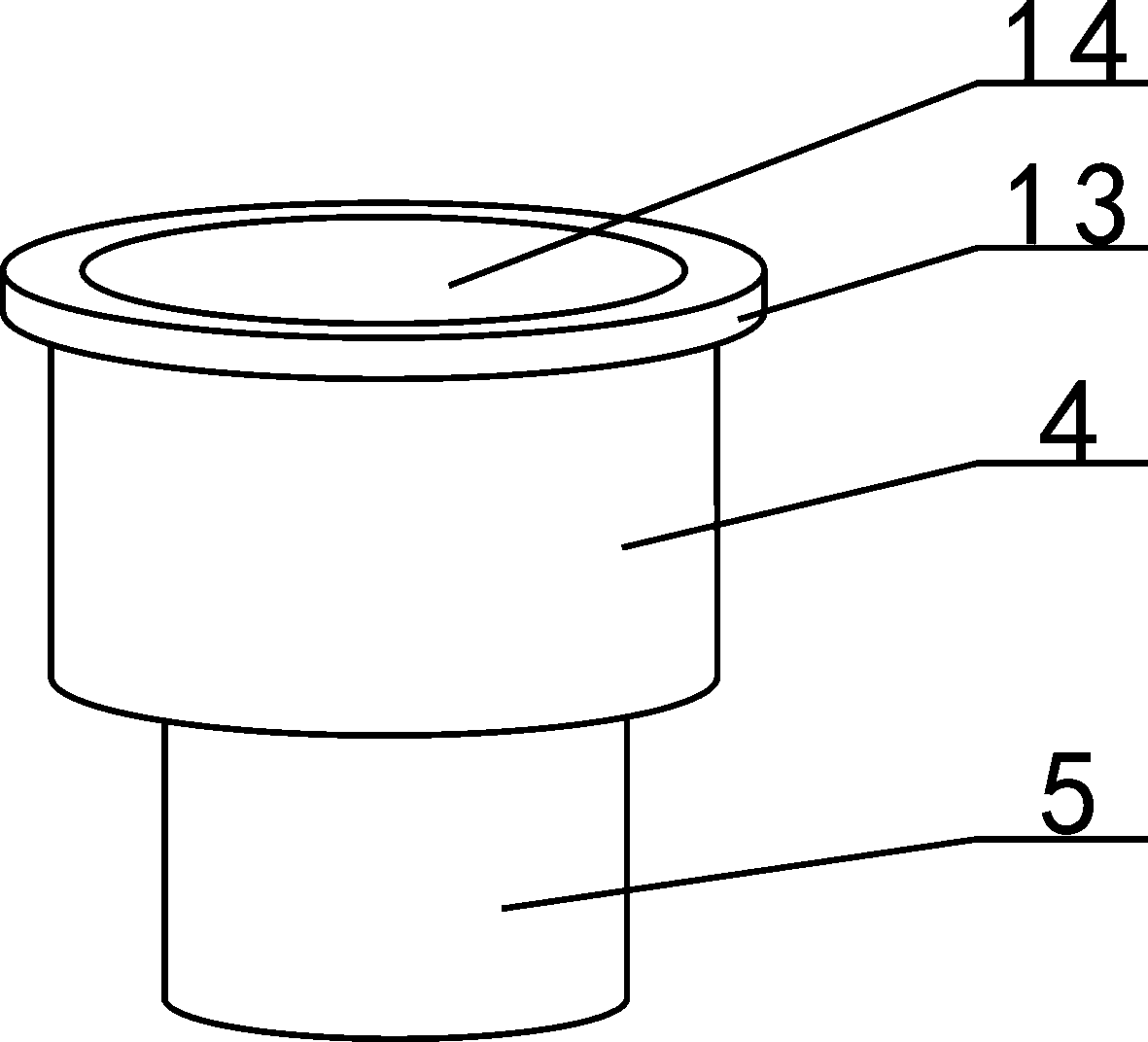

[0025] combined with Figure 1~6 The anti-volatility structure suitable for chemical liquid raw material barrels described in , includes a barrel body 11, an upper cover 1, an intubation tube in the barrel lid, a lifting cylinder 7, a spring 3, a sealing ring A6 and a lock ring 2, in the barrel body 11 The bung mouth 8 is provided with a loam cake 1, and the upper tube 4 of the intubation pipe in the bung lid is inserted in the bung mouth 8, and the protruding ring 13 on the outer edge of the upper end of the upper tube 4 is pressed on the upper end surface of the bun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com