A steel bar slitting machine for building construction

A technology for building construction and slitting machine, which is applied in the directions of cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. Improve processing efficiency and avoid the effect of rebar bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

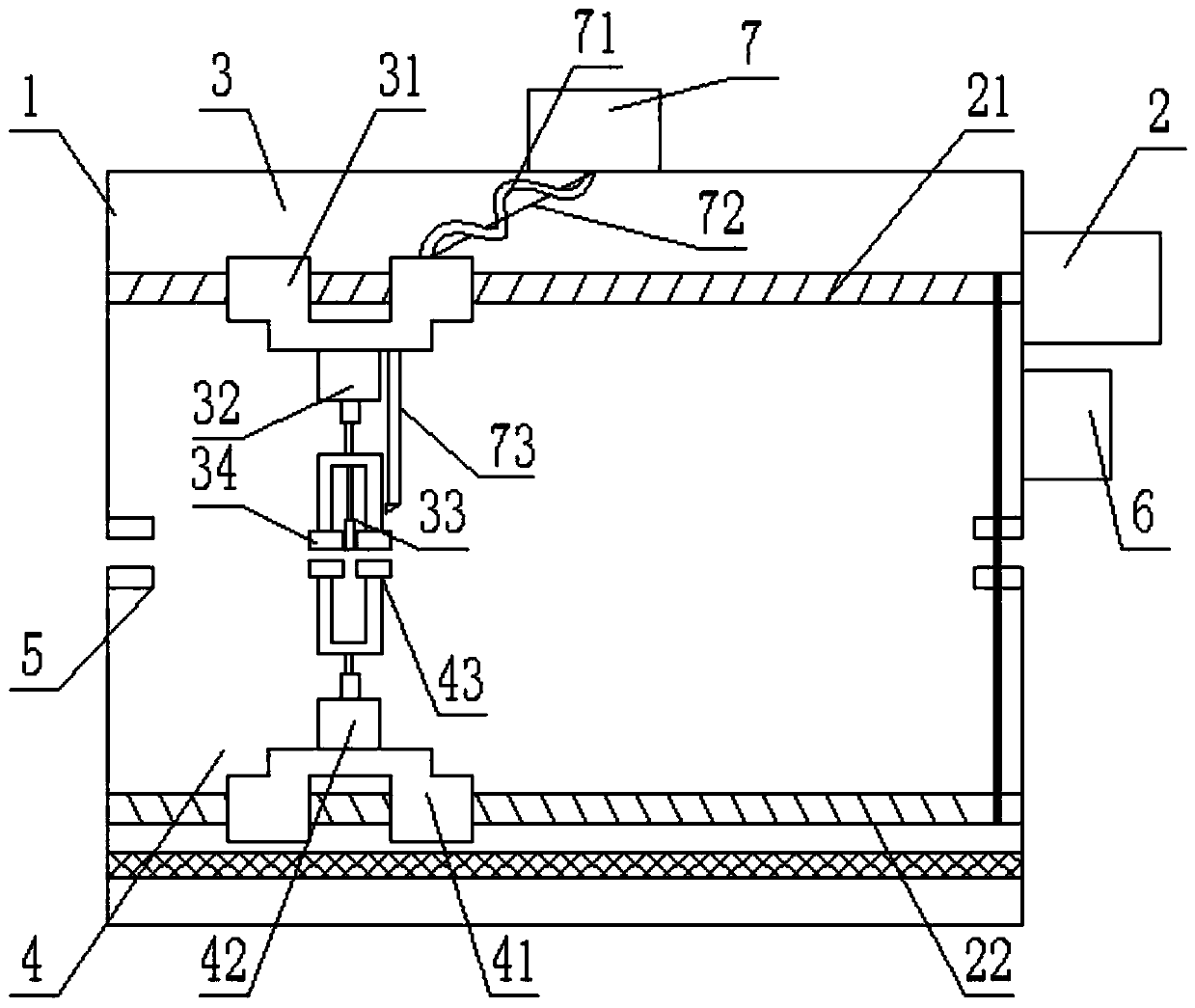

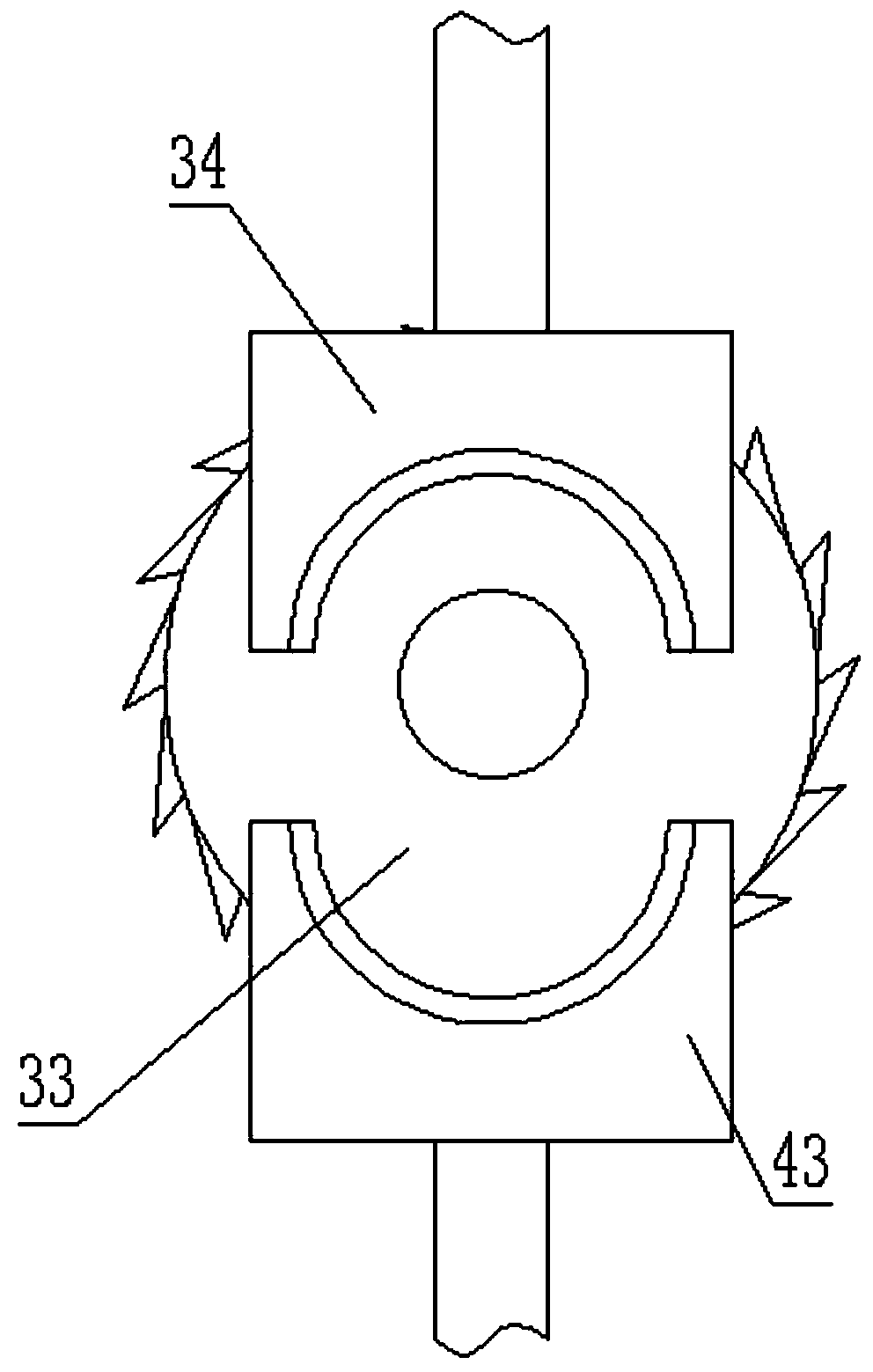

[0019] see Figure 1-2 , a steel bar slitting machine for building construction, comprising a closed casing 1 with a feed port and a discharge port on both sides and a stepping motor 2 positioned on the upper part of the outer wall of the casing 1, and a closed casing 1 is provided with a The driving screw 21 connected to the stepping motor 2 and the driven screw 22 parallel to the driving screw 21 and connected by transmission chain transmission, the driving screw 21 and the driven screw 22 are located on the upper and lower sides of the closed housing 1 respectively. The screw 21 is provided with a fixed cutting module 3 for fixing and cutting the steel bar, and the driven screw 22 is provided with a mobile cutting module 4 for fixing the steel bar; The slitting module 3 and the moving slitting module 4 will fix and cut the steel bars sent into the closed casing 1 by the feed port; the outer wall of the closed casing 1 is provided with a device for setting working parameters...

Embodiment 2

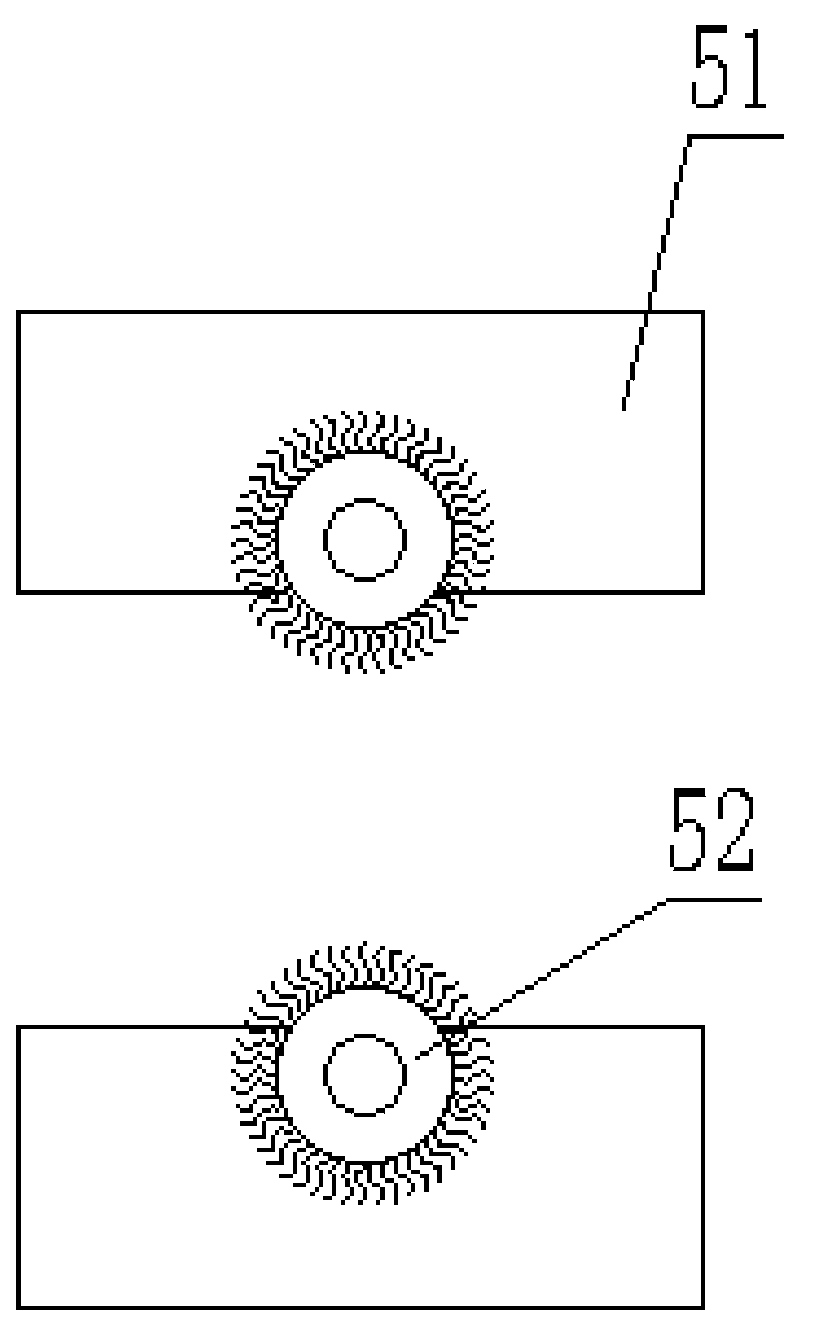

[0027] refer to figure 1 , image 3 , the difference with Embodiment 1 is that, in order to further ensure the working environment in the closed casing 1, and also in order to ensure the efficiency of cutting, a feed dust collector 5 is provided inside the feed port end of the closed casing 1. The dust collector 5 is composed of two fixed pieces 51 located on both sides of the upper and lower sides of the feed inlet. A brush 52 driven by a motor is arranged in the fixed piece 51. When the steel bar enters from the feed port, the brush 52 is started against the surface of the steel bar. Clean up to reduce surface dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com