Preparation method of composite silicon dioxide aerogel capable of adsorbing formaldehyde

A technology for composite silica and formaldehyde adsorption, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve problems such as poor stability, automatic analysis, and lack of specificity in activated carbon adsorption, and achieve No secondary pollution, specificity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

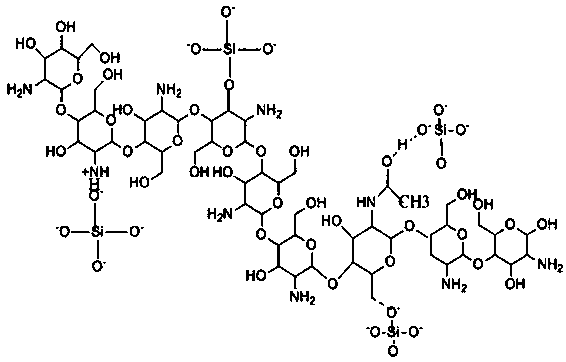

[0031] Embodiment 1: A kind of preparation method of the composite silica airgel that can adsorb formaldehyde comprises the following steps:

[0032]S1, measure 60-65ml tetraethyl orthosilicate (C 8 h 12 o 8 Si) In the Erlenmeyer flask, add 50ml of absolute ethanol to the Erlenmeyer flask at room temperature to mix evenly;

[0033] S2. Add 3-5g of chitosan powder to the mixed solution in S1, seal the mouth of the conical flask with a sealing film to prepare airtight reaction conditions, and use a stirring device to continuously stir the mixed solution in the conical flask. , the stirring time is 10-12h;

[0034] S3. While stirring the mixed solution, dropwise add 2.0-3.0ml of HF solution with a mass fraction of 5% to the mixed solution, continuously drop it for 14-16min, then seal it and let it stand for 10-12h, and get Translucent chitosan-silica composite gel;

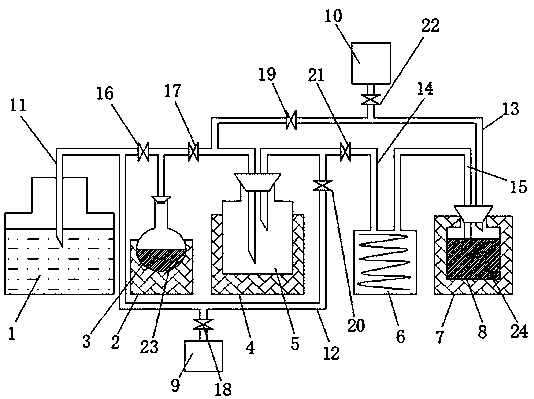

[0035] S4, take out the chitosan-silicon dioxide composite gel prepared in S3, soak and wash the composite ge...

Embodiment 2

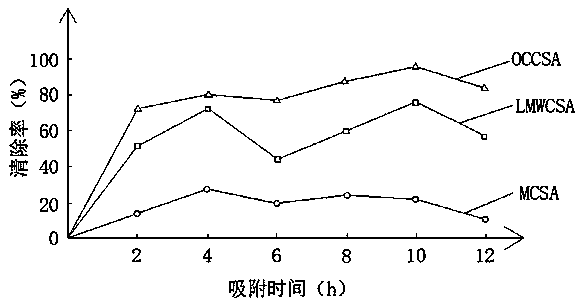

[0044] Embodiment 2: Based on Example 1 but differently, with high molecular chitosan (viscosity average molecular weight 200kDa) as raw material, 3g high molecular chitosan and 60ml tetraethyl orthosilicate (C 8 h 12 o 8 Si) was mixed according to the proportion to prepare a sealed reaction environment, and further pretreated the translucent composite airgel. After pretreatment, 10ml of epichlorohydrin, 8 drops of 70% perchloric acid and 200ml of Amino-modified polymer chitosan-silicon dioxide composite gel can be prepared by mixing the absolute ethanol evenly, and the amino-modified polymer chitosan-silicon dioxide composite gel is further acidified, and finally formaldehyde is used to The dynamic adsorption device analyzes the formaldehyde adsorption performance of the polymer composite gel. The measured results show that the maximum formaldehyde adsorption capacity of the polymer chitosan-silica composite airgel (MCSA) is 0.111mg / g, mainly Due to the higher viscosity-ave...

Embodiment 3

[0045] Embodiment 3: Based on Example 1 but differently, using low-molecular chitosan (viscosity-average molecular weight 3kDa) as raw material, 63ml tetraethyl orthosilicate and 4g are mixed to prepare a sealed reaction environment, and further The prepared translucent composite airgel is pretreated. After the pretreatment, use 12ml of epichlorohydrin, 9 drops of 70% perchloric acid and 220ml of dehydrated alcohol to mix evenly, and the amino-modified low Molecular chitosan-silicon dioxide composite gel, further acidify the amino-modified low-molecular-weight chitosan-silicon dioxide composite gel, add 10ml of ethylenediamine and 40ml of absolute ethanol to the composite gel Mix, mix evenly and soak in acetic acid to prepare low molecular chitosan-silica composite aerogel (LMWCSA), use formaldehyde dynamic adsorption device to analyze the formaldehyde adsorption performance of low molecular composite gel, low molecular weight The maximum formaldehyde scavenging rate of chitos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity average molecular weight | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com