Self-heating waistcoat

A self-heating, vest technology, applied in protective clothing, clothing features, clothing, etc., can solve the problems of thick clothes and uncomfortable wearing, and achieve the effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

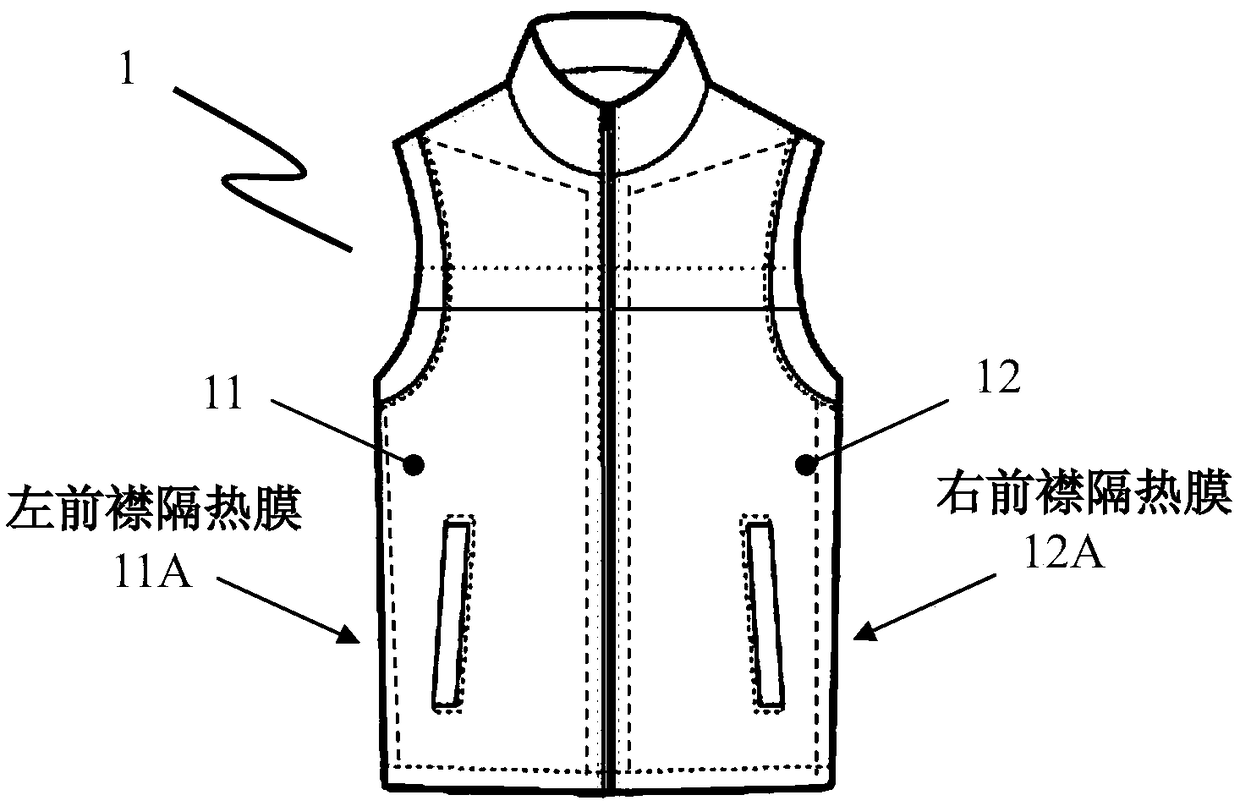

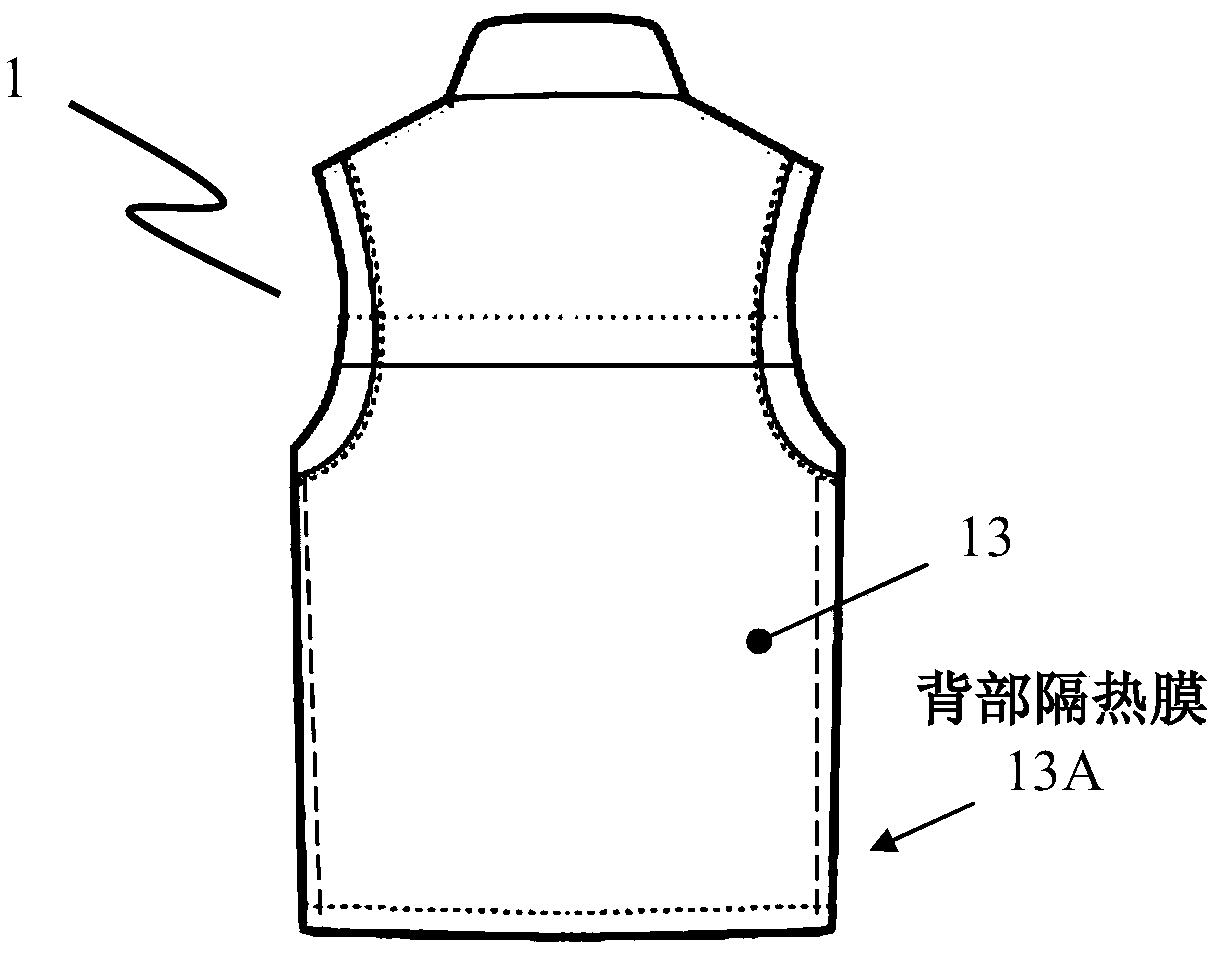

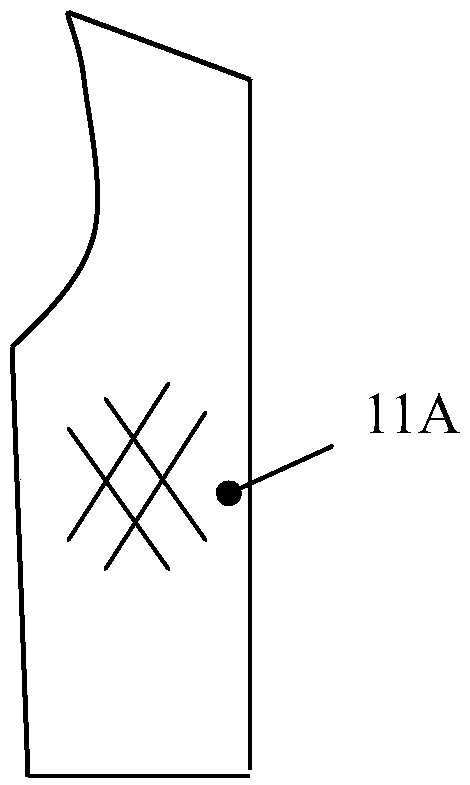

[0051] refer to Figure 1-Figure 4 : The dotted line in the figure shows the insulation film.

[0052] A self-heating vest, comprising an outer layer of fabric and an inner layer of fabric, characterized in that it also includes a heat insulating film (11A, 12A, 13A), and the heat insulating film is located between the outer layer of fabric and the inner layer of fabric.

[0053] The thermal insulation film adopts coated printing film.

[0054] Production steps:

[0055] (1) Divide the coated printing film into three parts, and process respectively: left front flap heat insulation film 11A, right front flap heat insulation film 12A, and back heat insulation film 13A.

[0056] (2) After cutting the cloth of the traditional waistcoat, when sewing, the left front skirt heat insulation film 11A, the right front skirt heat insulation film 12A, and the back heat insulation film 13A are arranged between the outer layer fabric and the inner layer fabric between.

[0057] According...

Embodiment 2

[0064] refer to Figure 1-Figure 4 :

[0065] A self-heating vest, comprising an outer layer of fabric and an inner layer of fabric, characterized in that it also includes a heat insulating film (11A, 12A, 13A), and the heat insulating film is located between the outer layer of fabric and the inner layer of fabric.

[0066] The heat insulation film adopts precious metal film.

[0067] Production steps:

[0068] (1) Divide the precious metal film into three parts, and process them respectively: the heat insulation film 11A of the left front skirt, the heat insulation film 12A of the right front skirt, and the heat insulation film 13A of the back.

[0069] (2) After cutting the cloth of the traditional waistcoat, when sewing, the left front skirt heat insulation film 11A, the right front skirt heat insulation film 12A, and the back heat insulation film 13A are arranged between the outer layer fabric and the inner layer fabric between.

[0070] According to the actual structu...

Embodiment 3

[0077] refer to Figure 1-Figure 4 :

[0078] A self-heating vest, comprising an outer layer of fabric and an inner layer of fabric, characterized in that it also includes a heat insulating film (11A, 12A, 13A), and the heat insulating film is located between the outer layer of fabric and the inner layer of fabric.

[0079] The heat insulating film adopts magnetron sputtering film.

[0080] Production steps:

[0081] (1) Divide the magnetron sputtering film into three parts, and process respectively: left front skirt heat insulation film 11A, right front skirt heat insulation film 12A, and back heat insulation film 13A.

[0082] (2) After cutting the cloth of the traditional waistcoat, when sewing, the left front skirt heat insulation film 11A, the right front skirt heat insulation film 12A, and the back heat insulation film 13A are arranged between the outer layer fabric and the inner layer fabric between.

[0083] According to the actual structure of the vest, the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com