A kind of laminated plate structure and pressing method of pcb pressing based on cushioning material

A cushioning material and board stacking technology, which is applied in multi-layer circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of difficult control of the thickness accuracy of the board, hollow board, and inability to fully meet the requirements of temperature and pressure buffering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

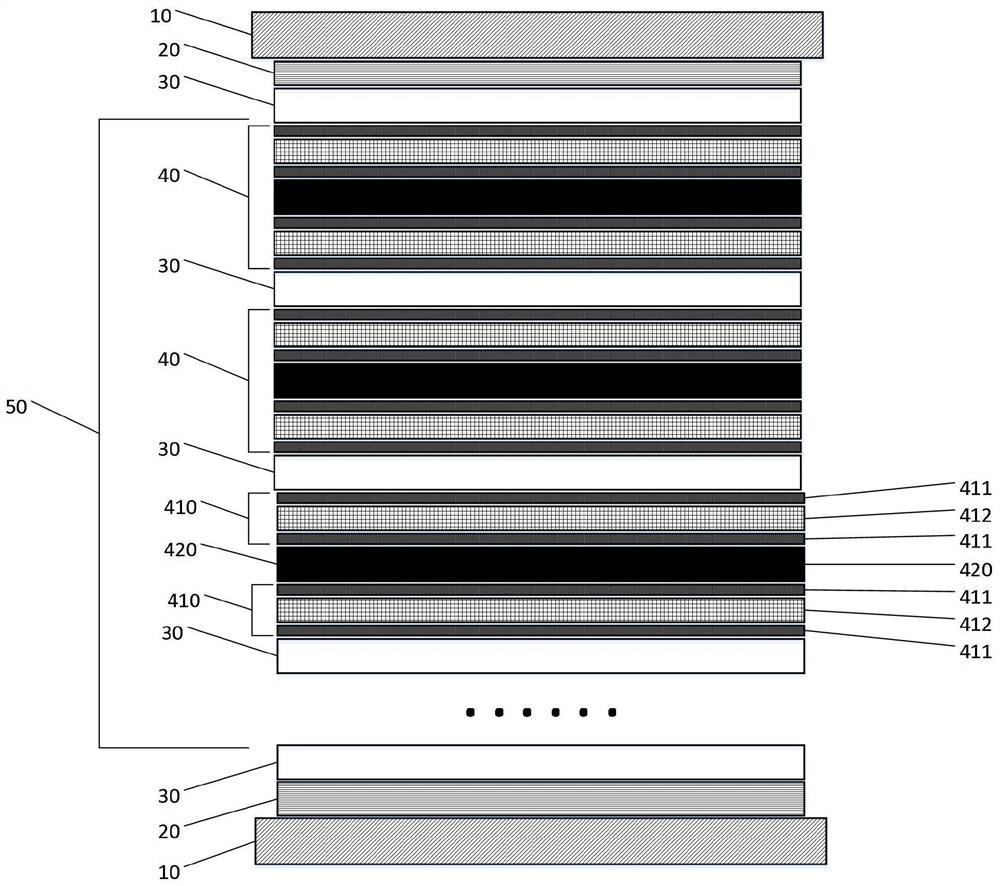

[0044] Embodiment 1, taking the lamination of a microwave twelve-layer board as an example.

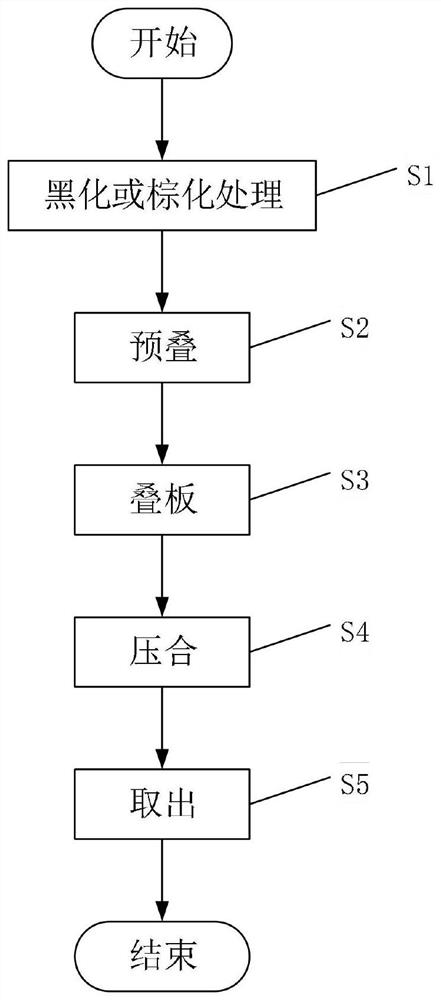

[0045] Depend on figure 2 Shown, a kind of pressing method of PCB pressing based on cushioning material, comprises the following steps:

[0046] S1, blackening or browning treatment is performed on the inner layer core board after the graphics are completed, and drying treatment is performed on the inner layer core board after the blackening or browning treatment; the blackening or browning treatment is to strengthen the inner layer The bonding force between the core board and the PP sheet.

[0047] S2, pre-stacking, the pre-stacking is to stack and fix the inner layer core board and PP sheet together according to the lamination diagram required by the production, and the inner layer core board and PP sheet after stacking and fixing are the said to-be-pressed Sheet 420;

[0048] The superimposed and fixed process is a pin-positioning lamination process pin-lam or a pinless positio...

Embodiment 2

[0060] Embodiment 2, taking the lamination of microwave four-layer board as an example.

[0061] A kind of pressing method based on the PCB pressing of cushioning material, comprises the following steps:

[0062] S1, blackening or browning treatment is performed on the inner layer core board after the graphics are completed, and drying treatment is performed on the inner layer core board after the blackening or browning treatment; the blackening or browning treatment is to strengthen the inner layer The bonding force between the core board and the PP sheet.

[0063] S2, pre-stacking, the pre-stacking is to stack and fix the inner layer core board and PP sheet together according to the lamination diagram required by the production, and the inner layer core board and PP sheet after stacking and fixing are the said to-be-pressed Sheet 420;

[0064] The superimposed and fixed process is a pin-positioning lamination process pin-lam or a pinless positioning lamination process mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com