Test method for simulating gravel stratum grouting diffusion radius under flowing water environment

A technology of diffusion radius and test method, which is applied in the field of grouting material performance testing equipment, can solve the problems that the medium filling device cannot be opened, grouting materials, and coarse particles such as cement cannot be used, so as to achieve high accuracy of grout diffusion parameters, reduce Small design error, good stability in dynamic water environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

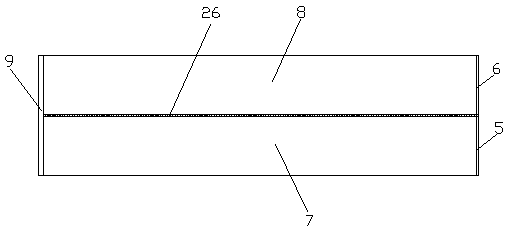

[0047] A test method for simulating the diffusion radius of grouting in gravel formations under dynamic water environment, comprising the following steps:

[0048] a, collect the gravel sample on site, and fill it into the stainless steel box 2 of the test device in multiple layers, and control the filling thickness through the telescopic screw 11 and the sand retaining plate 10;

[0049] b. Insert the grouting pipe 14 and the water injection pipe 15 vertically into the gravel sample respectively, and adjust the overflow pressure of the overflow valve 18 according to the simulated formation stress value;

[0050] c. Turn on the grouting pump 3 and the water injection pump 4 respectively, apply the grouting pressure until the pressure reaches the set value, the grouting slurry enters the gravel sample through the grouting pipe 14, apply the water injection pressure until the water pressure reaches the set value, the water Enter the gravel sample through the water injection pipe...

Embodiment 2

[0055] A test method for simulating the diffusion radius of grouting in gravel formations under dynamic water environment, comprising the following steps:

[0056] a, collect the gravel sample on site, and fill it into the stainless steel box 2 of the test device in multiple layers, and control the filling thickness through the telescopic screw 11 and the sand retaining plate 10;

[0057] b. Insert the grouting pipe 14 and the water injection pipe 15 vertically into the gravel sample respectively, and adjust the overflow pressure of the overflow valve 18 according to the simulated formation stress value;

[0058] c. Turn on the grouting pump 3 and the water injection pump 4 respectively, apply the grouting pressure until the pressure reaches the set value, the grouting slurry enters the gravel sample through the grouting pipe 14, apply the water injection pressure until the water pressure reaches the set value, the water Enter the gravel sample through the water injection pipe...

Embodiment 3

[0064] A test method for simulating the diffusion radius of grouting in gravel formations under dynamic water environment, comprising the following steps:

[0065] a, collect the gravel sample on site, and fill it into the stainless steel box 2 of the test device in multiple layers, and control the filling thickness through the telescopic screw 11 and the sand retaining plate 10;

[0066] b. Insert the grouting pipe 14 and the water injection pipe 15 vertically into the gravel sample respectively, and adjust the overflow pressure of the overflow valve 18 according to the simulated formation stress value;

[0067] c. Turn on the grouting pump 3 and the water injection pump 4 respectively, apply the grouting pressure until the pressure reaches the set value, the grouting slurry enters the gravel sample through the grouting pipe 14, apply the water injection pressure until the water pressure reaches the set value, the water Enter the gravel sample through the water injection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com