Device and method for in-situ observation of heat flow density of mould powder for continuous casting in phase change process

A technology of continuous casting mold flux and heat flow density, which is applied in the field of high temperature pyrometallurgy, can solve the problems of insufficient simulation of environmental conditions, high consumption of raw materials, and high experimental cost, and achieves a wide range of testing applications, low experimental danger, and simple operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

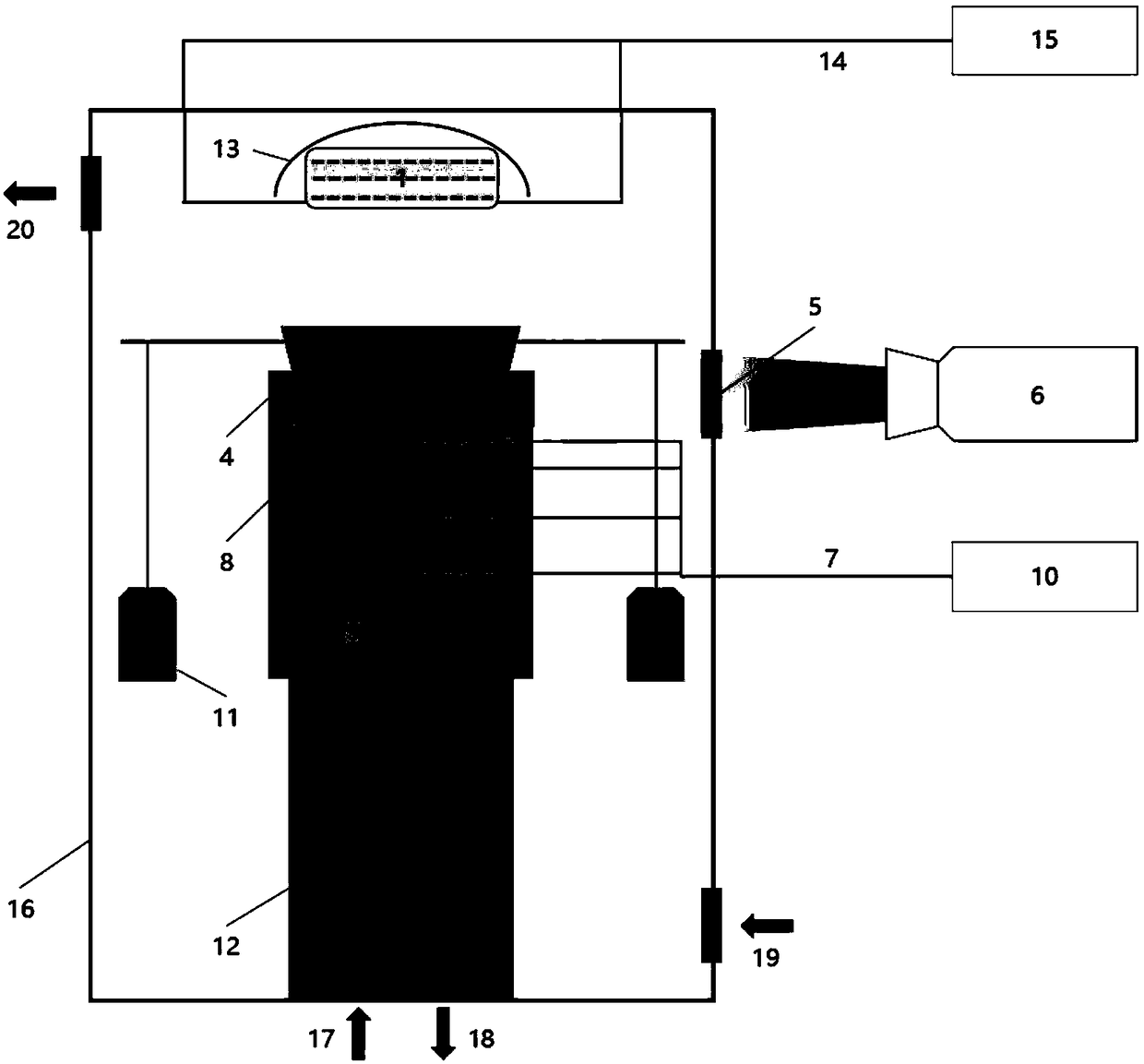

[0060] see Figure 1-Figure 7 , a device for in-situ observation of the heat flux during the phase transition process of continuous casting mold flux, including a heat-insulating enclosure 16, a sample chamber 3, a loading system, a heating system, a temperature measurement and recording component, and an infrared thermometer 6. The sample chamber 3 is set in The airtight inner cavity of the heat-insulating enclosure 16 is used to hold samples. The loading system is used to apply load to the sample from the top. The side wall of the sealed inner cavity is provided with a vent 19 and a gas outlet 20. The atmosphere gas is introduced into the sealed inner cavity through the vent of the external atmosphere supply device, so as to achieve the adjustment of the sample. The purpose of the atmosphere in the chamber 3 is to realize the simulation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com