Sluice valve and manufacturing process of valve body lining part

A technology for a lining piece and a knife gate valve, which is applied in the field of the manufacturing process of the knife gate valve and the lining piece in the valve body, can solve the problems of increasing the use and maintenance cost, the valve body cannot be sealed, and the valve body is worn, so as to reduce the maintenance cost and improve the Sealing, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

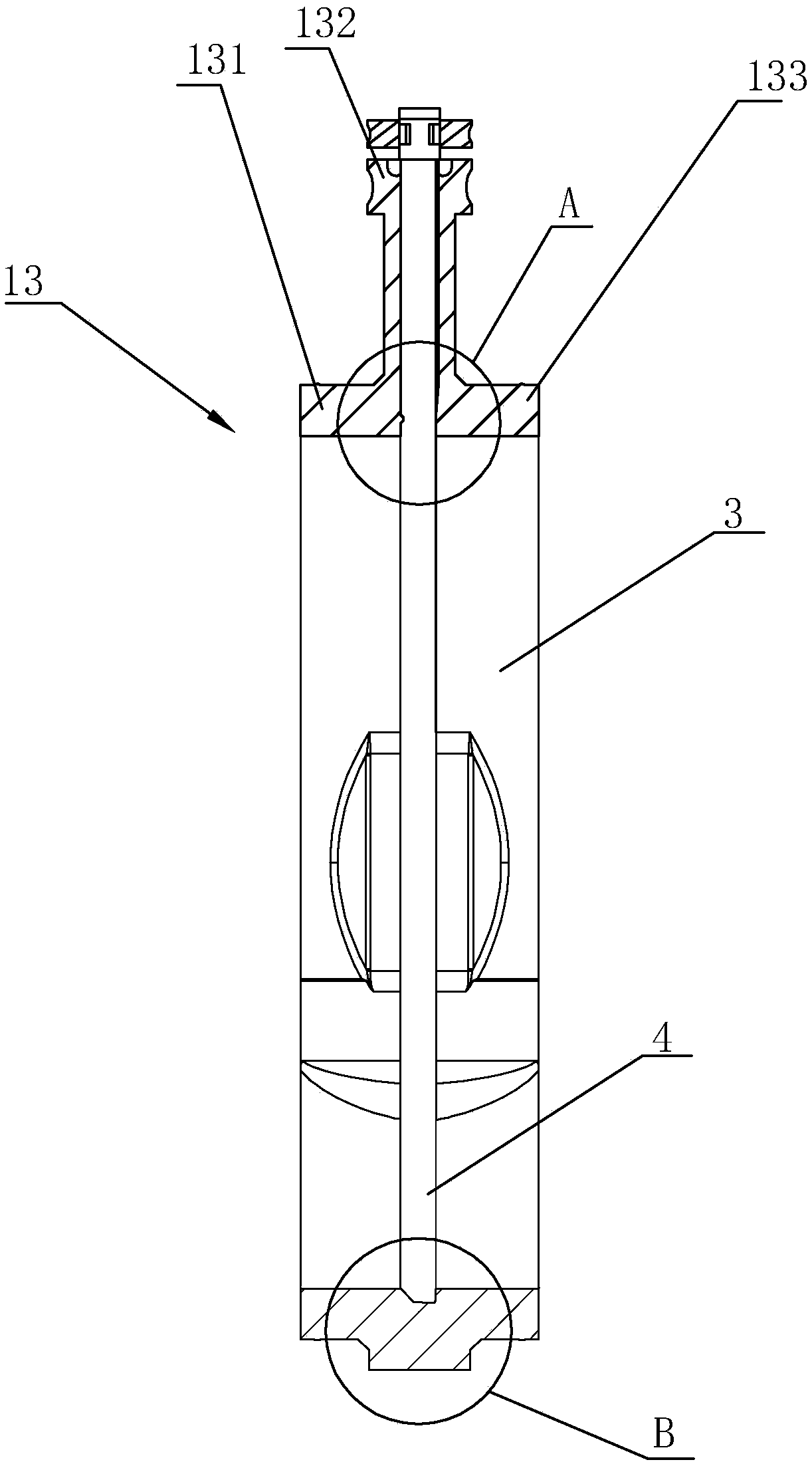

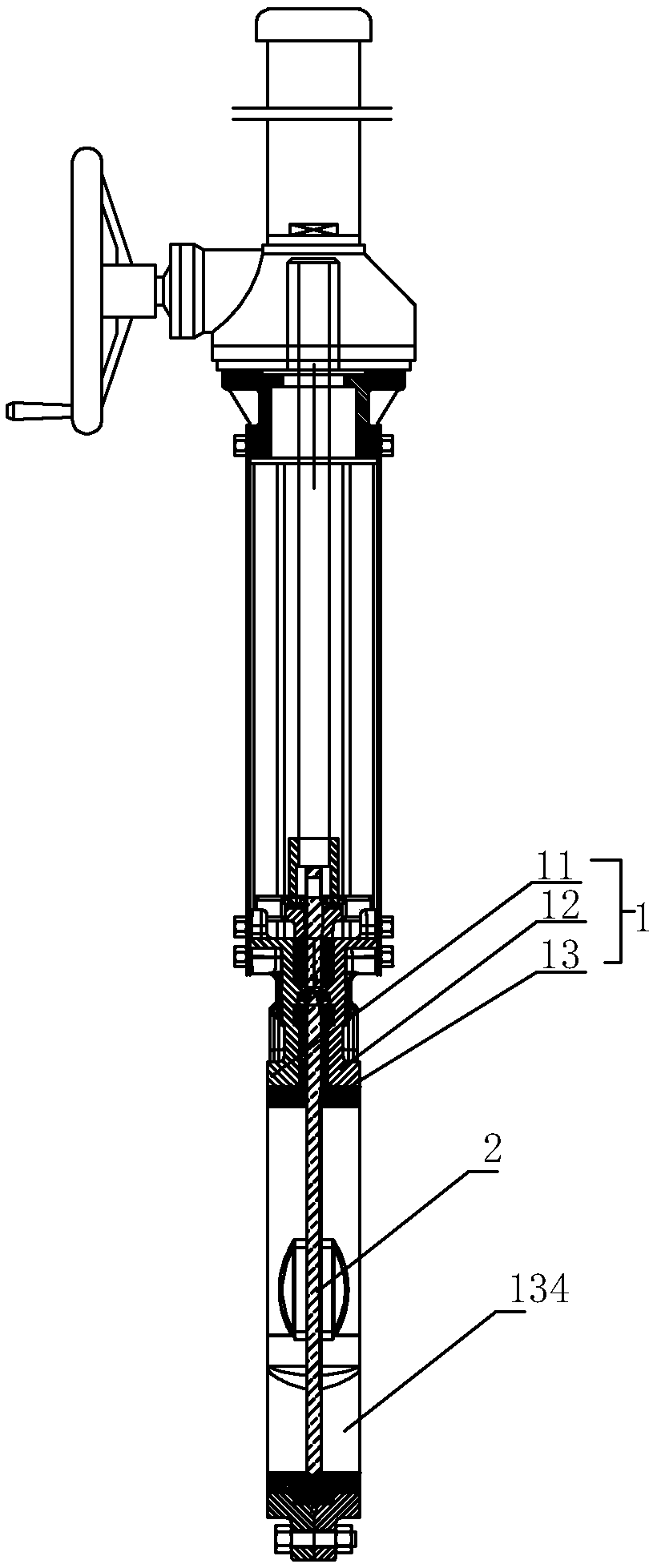

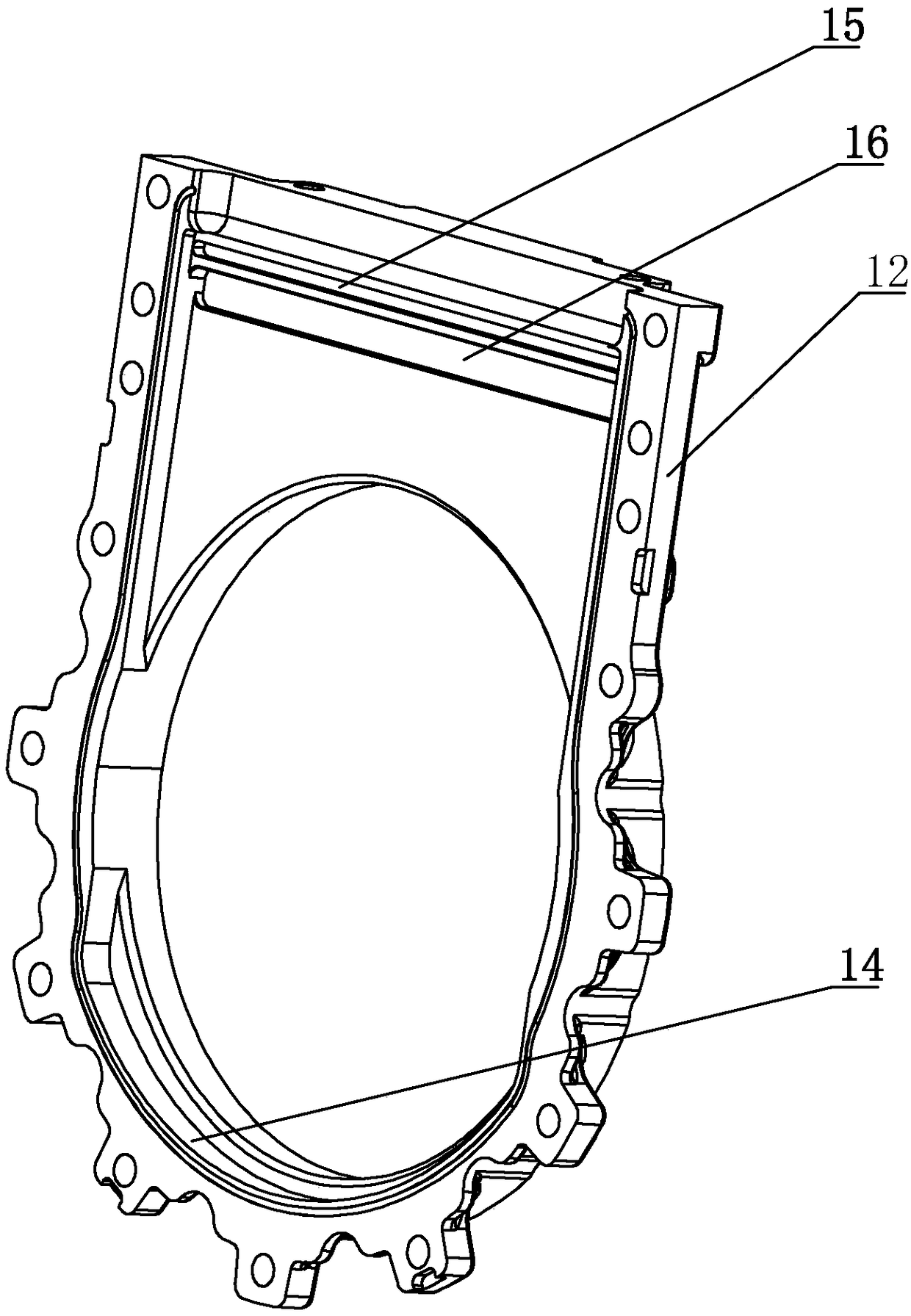

[0030] Refer to attached Figure 1 to Figure 8 A knife gate valve of the present invention will be described in further detail.

[0031] From figure 1 It can be seen that a knife gate valve includes a valve body 1 and a gate plate 2, the valve body 1 includes a left valve body 11, a right valve body 12 and a valve inner lining 13, and the valve inner lining 13 adopts a specific elastic The non-metallic material is integrally formed, and the elastic non-metallic material can be wear-resistant polyurethane and other rubber materials, wherein the left valve body 11 and the right valve body 12 are made of traditional metal materials, and the left valve body 11 and the right valve body 12 are respectively located on the left and right sides of the valve body liner 13, the left valve body 11 and the right valve body 12 are pressed against the valve body liner 13 by screws, wherein the opposite surfaces of the left valve body 11 and the right valve body 12 are respectively A sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com