Pump body components, casting molds and rotary compressors

A rotary compressor and casting mold technology, applied in the field of compressors, can solve problems such as compressor jamming, achieve the effect of improving safety and reliability, and improving the jamming problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

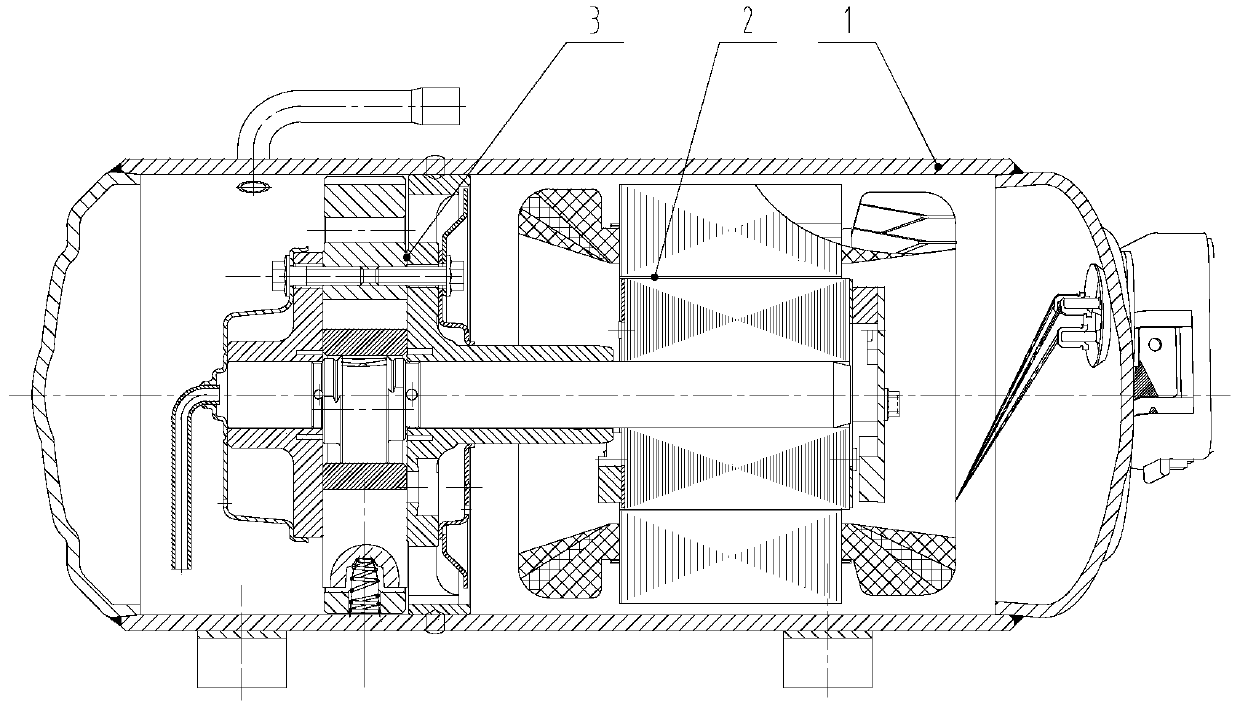

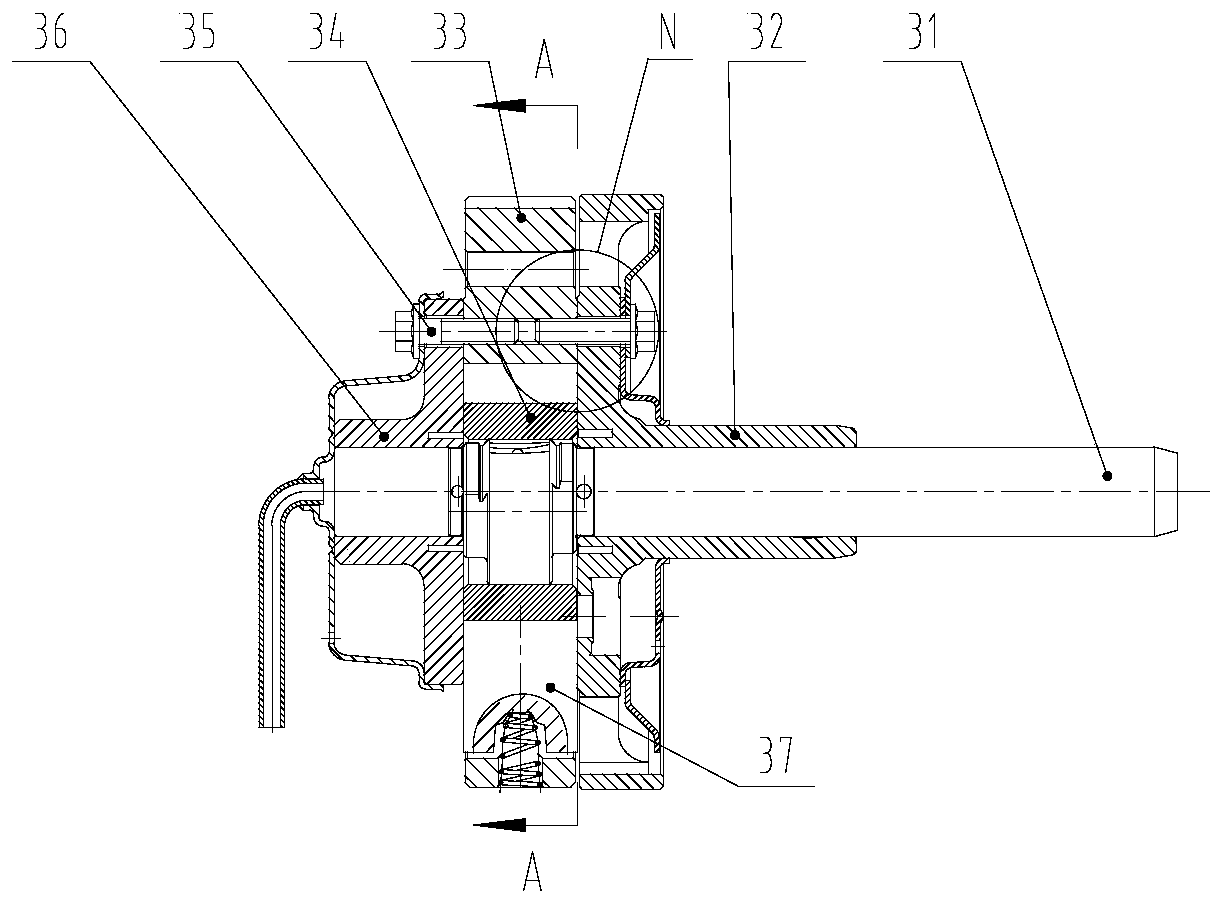

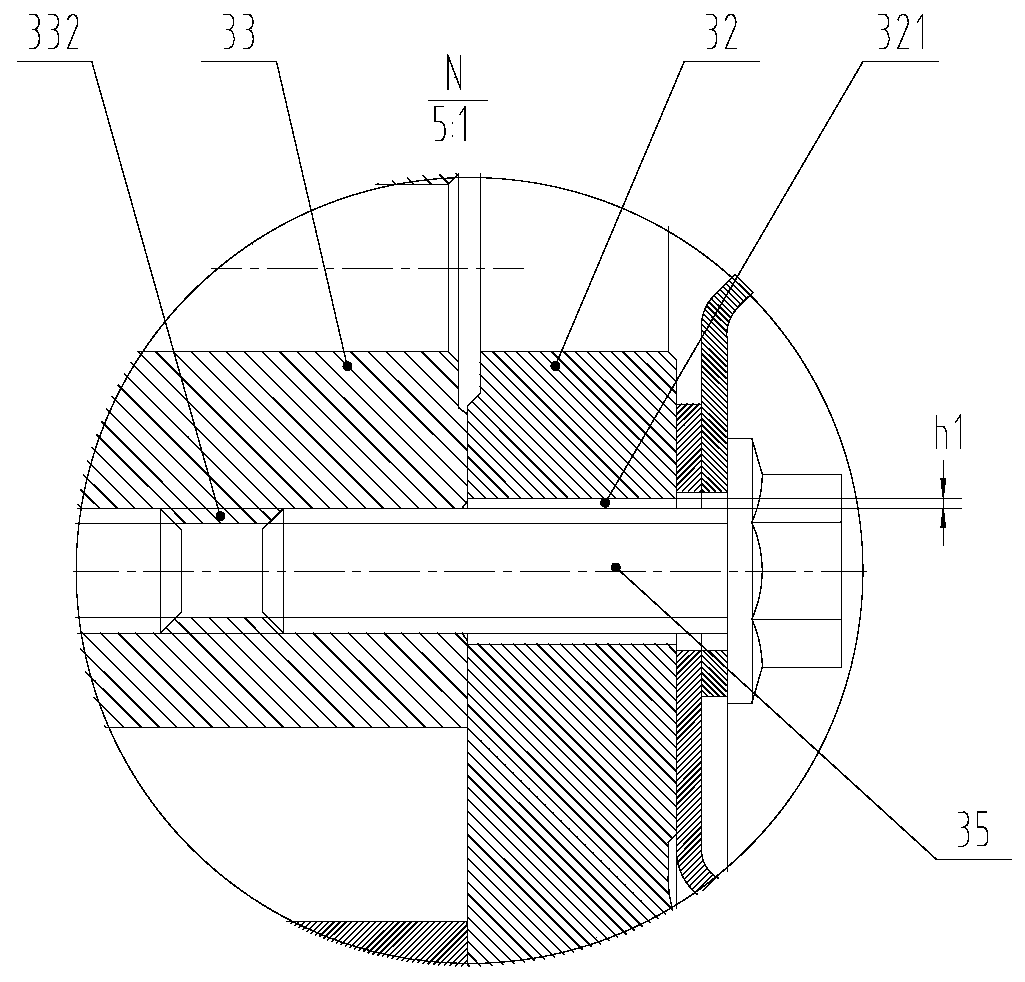

[0042] see in conjunction Figure 1 to Figure 16 As shown, according to the embodiment of the present invention, the pump body assembly includes a cylinder 3 and a first bearing 1 and a second bearing 2 arranged at both ends of the cylinder 3, the cylinder 3 and the first bearing 1 are integrally formed; and / or, the cylinder 3 It is integrally formed with the second bearing 2.

[0043] When the cylinder 3 and the first bearing 1 are integrally formed, there is no fit gap between the cylinder 3 and the first bearing 1 as a whole, so that the cylinder 3 and the first bearing 1 can be eliminated under the strong impact load of the pump body. Compressor jamming caused by relative displacement; when the cylinder 3 and the second bearing 2 are integrally formed, the cylinder 3 and the second bearing 2 can be formed as a whole without a fit gap, so the pump body can be eliminated. Under a strong impact load, the relative displacement between the cylinder 3 and the second bearing 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com