A heating method for rolling pure iron flat steel in a blooming mill

A heating method and blooming mill technology, applied in the field of pressure processing and rolling, can solve the problems of billet corner cracks and scraps, and achieve the effect of preventing rapid temperature drop and avoiding edge and corner cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

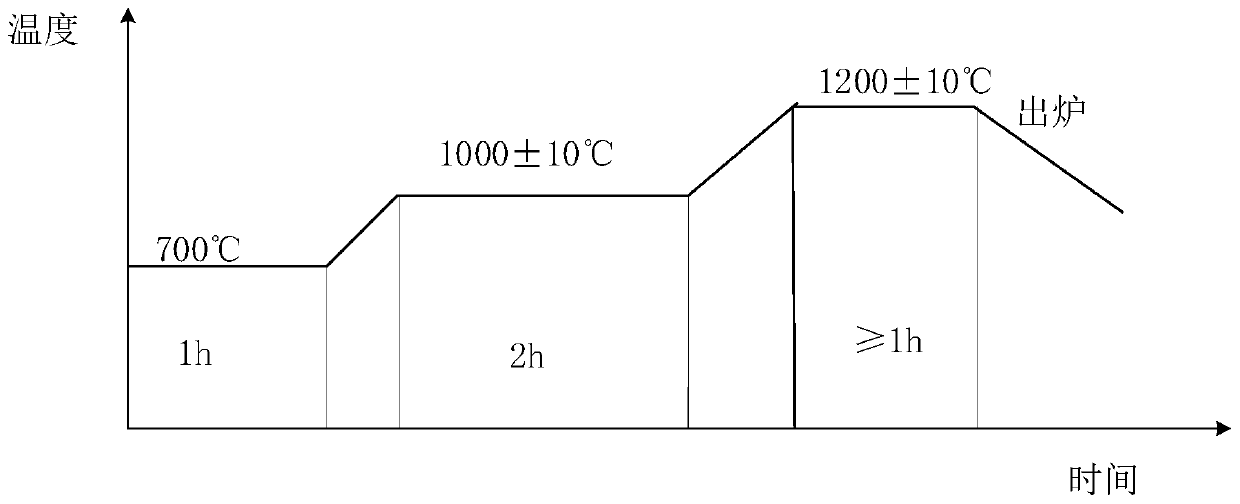

Image

Examples

Embodiment 1

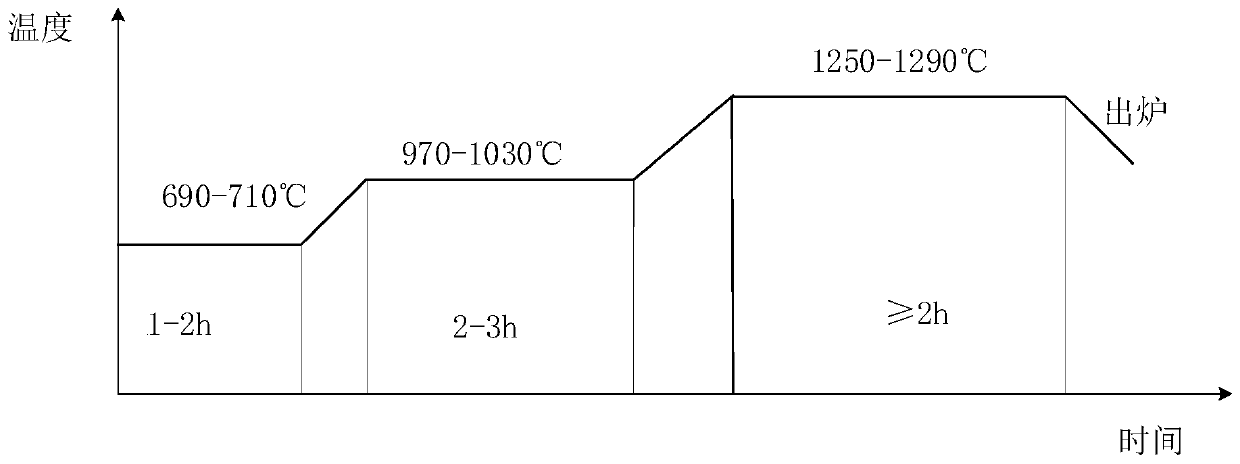

[0051] YT2 pure iron flat steel is rolled on the 1000mm blooming mill of the profile factory. The raw material is 220mm*630mm to cut the continuous casting slab. The finished product specification after rolling is 110mm*215mm. Heat the pure iron flat steel in a soaking furnace to 690-710℃ for 1-2 hours, then heat the pure iron flat steel to 990-1010℃ for 2-3 hours, continue to heat the pure iron flat steel, The temperature is raised to 1260-1280°C, the billet is hoisted out of the heating furnace after holding for 2 hours, and is transported to the roller table of the rolling mill for rolling. Before rolling, the surface temperature of the pure iron flat steel is detected. When the billet temperature is 1150- At 1180℃, rolling can be carried out. After the end of production, the surface cracks of pure iron flat steel were counted. The surface quality of YT2 pure iron flat steel was improved, and the unplanned product rate caused by surface cracks was 3%.

Embodiment 2

[0053] YT2 pure iron flat steel is rolled on the 1000mm blooming mill of the profile factory. The raw material is 220mm*630mm to cut the continuous casting slab. The finished product specification after rolling is 110mm*215mm. Heat the pure iron flat steel in a soaking furnace to 690-700°C for 1 hour, then heat the pure iron flat steel to 970-1000°C for 2-3 hours, and continue to heat the pure iron flat steel to increase the temperature To 1250-1270℃, after holding for 2 hours, the billet is hoisted from the heating furnace and transported to the roller table of the rolling mill for rolling. Before rolling, the surface temperature of the pure iron flat steel is detected, when the temperature is 1150-1180℃ , Can be rolled. After the end of production, the surface cracks of the pure iron flat steel were counted. The surface quality of the YT2 pure iron flat steel was improved, and the unplanned product rate caused by the surface cracks was 4%.

Embodiment 3

[0055] DT4 pure iron flat steel is rolled by the 1000mm blooming mill of the profile factory. The raw material is 220mm*630mm to cut the continuous casting slab. The finished product specification after rolling is 110mm*215mm. Heat the pure iron flat steel in a soaking furnace to 700-710°C for 1-2 hours, then heat the pure iron flat steel to 1000-1030°C for 2 hours, and continue to heat the pure iron flat steel to heat up To 1260-1290℃, the billet is hoisted out of the heating furnace after holding for 4 hours, and is transported to the roller table of the rolling mill for rolling. Before rolling, the surface temperature of the pure iron flat steel is detected, when the temperature is 1150-1180℃ , Can be rolled. After the end of production, the surface cracks of pure iron flat steel were counted. The surface quality of DT4 pure iron flat steel was improved, and the unplanned product rate caused by surface cracks was 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com