A method for reinforcing natural rubber

A technology of natural rubber and natural latex, which is applied in the field of reinforcing natural rubber, can solve the problems of flying dust, uneven mixing, endangering the health of workers, etc., and achieves the effects of low price, difficulty in eating flour, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of modified reinforcing filler aqueous solution:

[0030] (1) Surface modification of reinforcing fillers

[0031] ①Preparation of modified nano-diamond:

[0032] The nano-diamond is synthesized by the detonation method, and the obtained nano-diamond raw powder is not subjected to any treatment, the content of the nano-diamond is 55wt%-75wt%, and the particle size is from hundreds of nanometers to more than ten microns.

[0033] The obtained nano-diamond raw powder 10 is placed in a 250mL three-necked flask, and 150g of concentrated sulfuric acid (98%) is added, then 10g of potassium permanganate is weighed and ground to fine particles; the three-necked flask is heated to 100°C, pre- Heat for 30 minutes, slowly add the ground potassium permanganate, and react at 220°C for 5 hours. After the reaction is completed, take out the reaction liquid, centrifuge to about pH=4, and dry to obtain oxidized nano-diamonds.

[0034] The oxidized nano-diamond of 1 weight ...

Embodiment 2

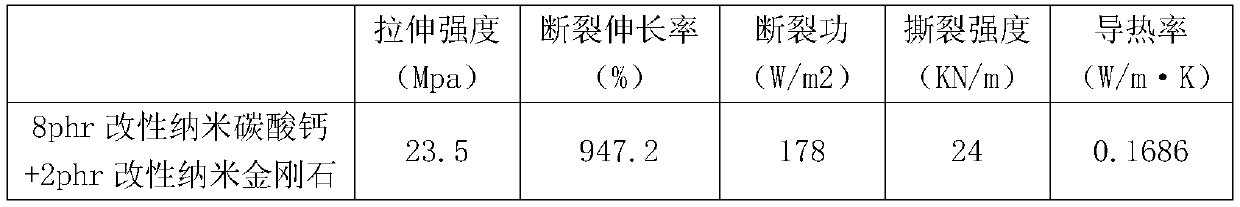

[0040] (1) Taking natural rubber dry glue as 100 parts by weight (15g), weigh 2 parts by weight (0.3g) of modified nano-diamond, modified nano-calcium carbonate (Nano-CaCO 3 ) 8 parts by weight (1.2g), 267 parts by weight of agate balls (40g) are added in the ball mill jar, meanwhile, add 0.15g of sodium lauryl sulfate of two kinds of modified fillers gross mass 1 / 10, add 550 parts by weight ( 82.5 g) of distilled water was prepared into a solution with a mass concentration of 1 / 50, and ball milled at a speed of 560 rpm for 2 hours to obtain a modified aqueous solution of reinforcing filler.

[0041] (2) Preparation of reinforced natural rubber

[0042] The obtained modified reinforcing filler aqueous solution is added to 25g of 60% natural rubber latex by mass fraction, and 493 parts by weight (74g) of distilled water is added to form a 10% latex solution, stirred for 24h, and then mixed with 20% CaCl 2 Alcohol aqueous solution (1 weight part anhydrous CaCl 2 , 2 parts by w...

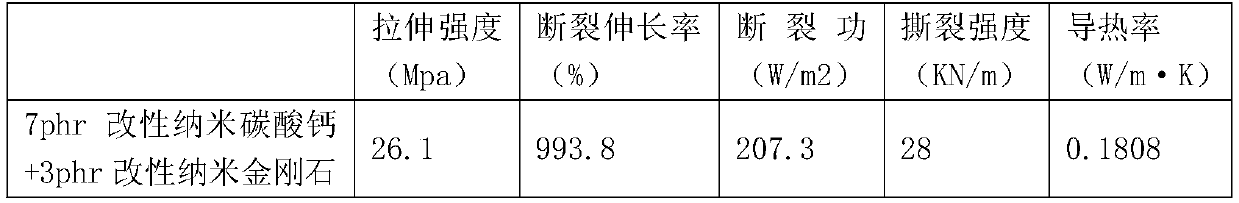

Embodiment 3

[0049] Taking natural rubber dry glue as 100 (15g) parts by weight, take modified nano-diamond (ODND) 3 parts by weight (0.45g) and modified nano-calcium carbonate (Nano-CaCO ) 7 parts by weight (1.05 g), 267 parts by weight (40g) of agate beads are added to the ball mill jar, and at the same time, sodium lauryl sulfate (0.15g) of 1 / 10 of the total mass of the two modified fillers is added, and 550 parts by weight (82.5g) of distilled water are added Prepare a solution with a mass concentration of 1 / 50, and ball mill for 2 hours at a speed of 560 rpm.

[0050] The two filler mixed liquids that have been ball milled are added to 25g of 60% natural rubber latex by mass fraction, and 493 parts by weight (74g) of distilled water are added to form a 10% latex solution, stirred for 24h, and then mixed with 20% CaCl 2 Alcohol aqueous solution (1 weight part of anhydrous CaCl2, 2 weight parts of absolute ethanol, 2 weight parts of distilled water) is demulsified, repeatedly extruded, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com