Hooking type grounding hook with monitoring function

A monitoring module and hook body technology, applied in the direction of connection, measurement of electricity, short-circuit test, etc., can solve the problems of difficult to connect successfully, hidden dangers to staff safety, difficult to use, etc. Effectiveness of management, standardized use and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

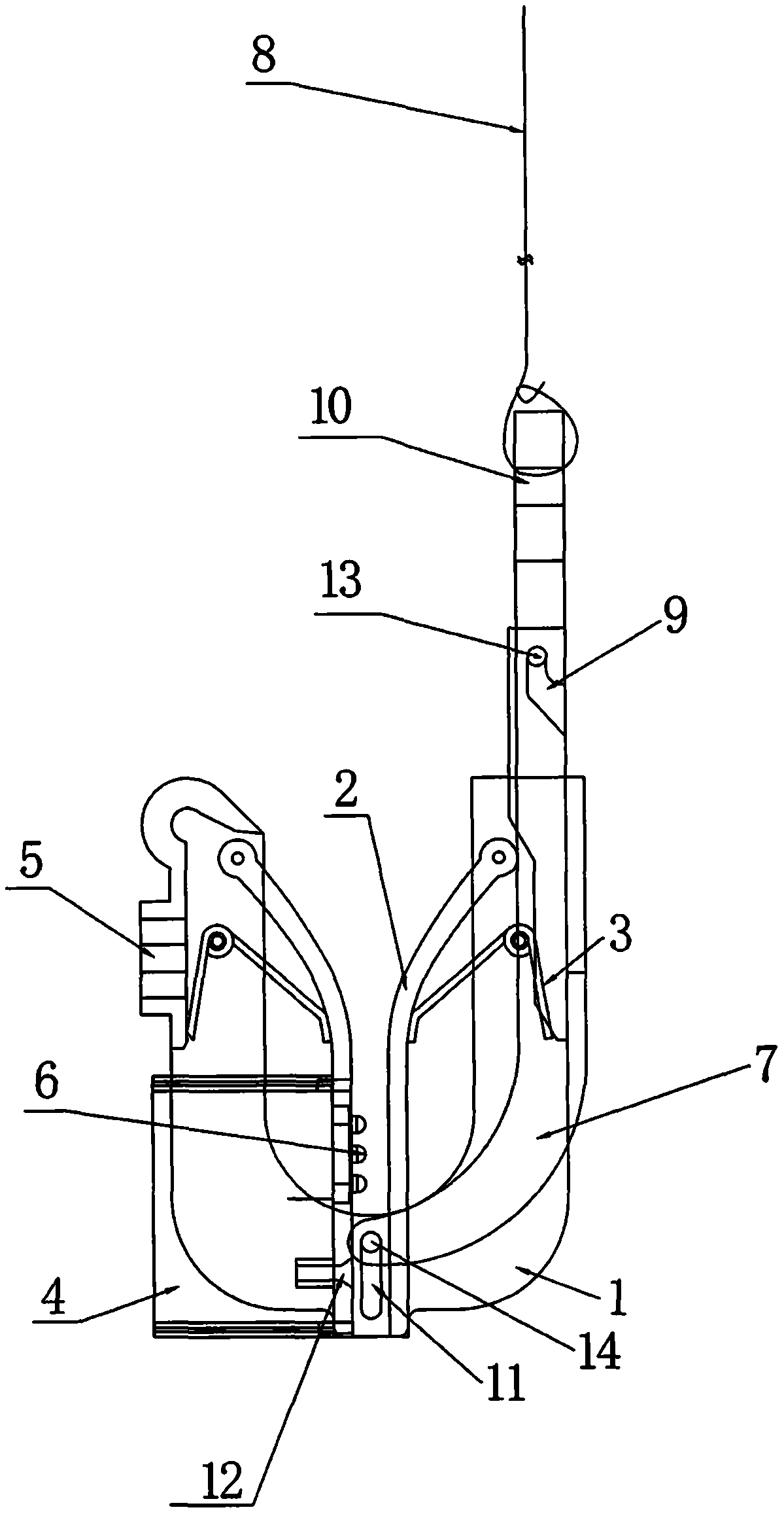

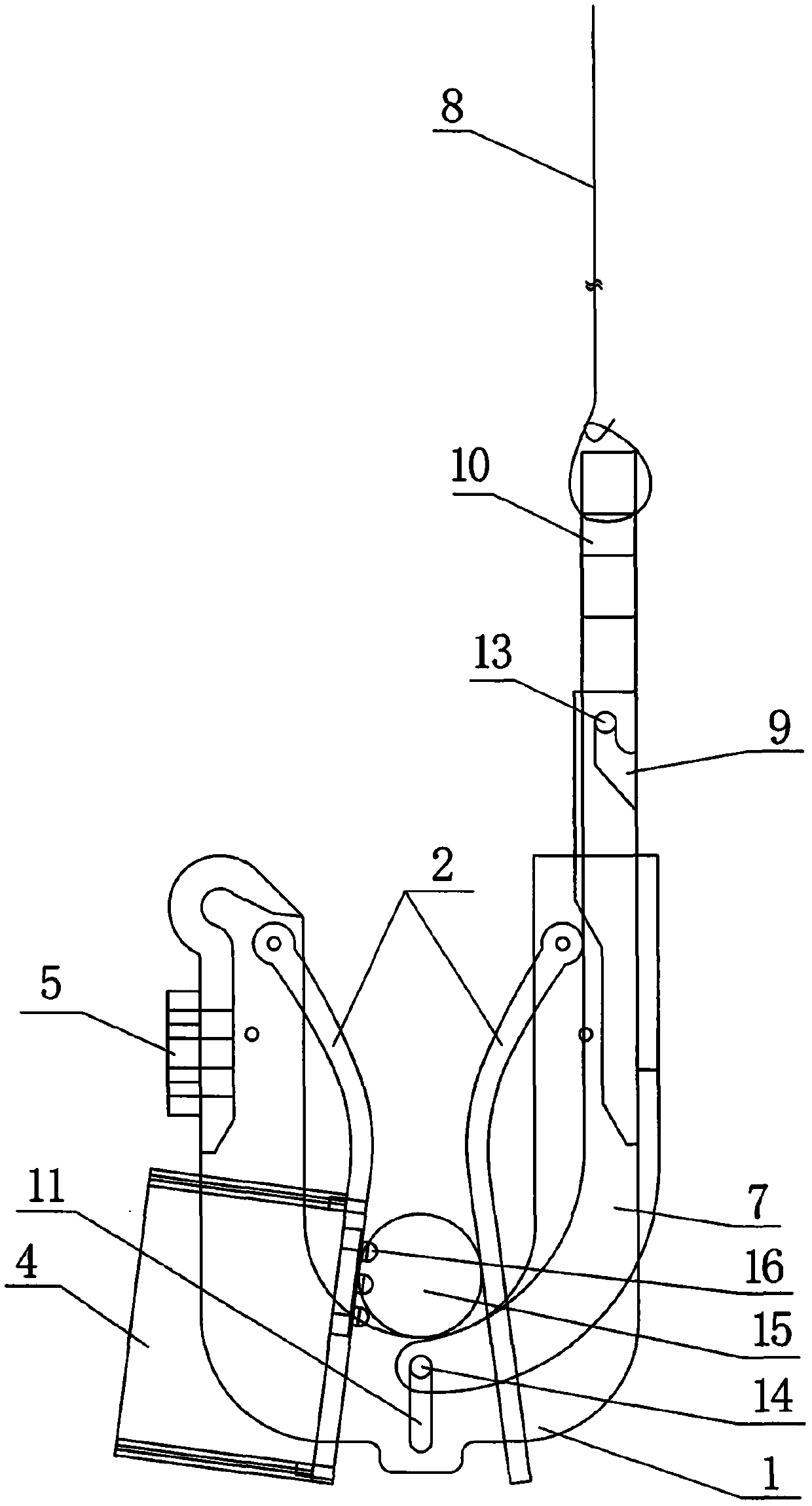

[0020] Such as figure 1 As shown, put the two knuckle springs 3 into the hook grooves at the left and right ends of the grounding hook body 1, insert cotter pins into the two spring installation holes on the grounding hook body 1, and fix the knuckle spring 3 on the grounding hook body 1. On the hook body 1. Install the monitoring module 4 on one of the clamping knuckles 2, put the two clamping knuckles 2 into the hook grooves at the left and right ends of the grounding hook body 1, and fix them on the hook body 1 through the cotter pin, clamp the wire The diameter of the mounting hole on the knuckle 2 is slightly larger than the diameter of the fixed cotter pin, and the two are movably connected.

[0021] The monitoring module 4 is equipped with an electrode 6 and a hook body electrode screw 12 connected with the clamping knuckle 2, and the electrode 6 and the hook body electrode screw 12 are respectively connected with the wire-hanging detection circuit inside the monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com