Preparation method and application of acetylated sodium hyaluronate

A technology of sodium hyaluronate and hyaluronic acid, applied in the field of preparation of acetylated sodium hyaluronate, can solve the problems of complicated process, large amount of organic solvent used and the like, achieve simple preparation process, reduce production process and shorten production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

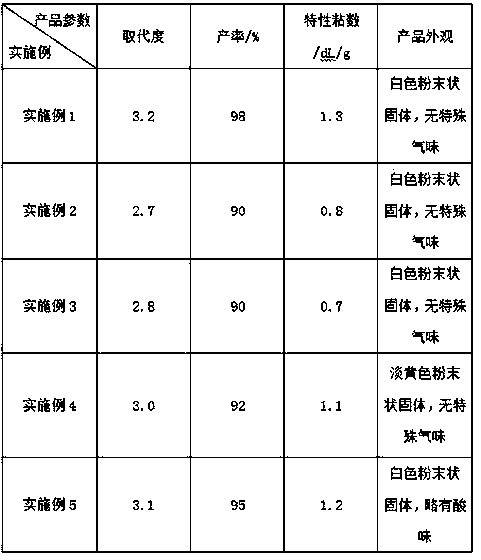

Examples

Embodiment 1

[0026] Take 5g of sodium hyaluronate powder with a molecular weight of 1300 kDa, add it to a 250ml three-necked flask, use 30ml acetic acid and 60ml acetic anhydride (V 乙酸 :V 乙酸酐 = 1:2) as an acylation reagent and reaction solvent, under mechanical stirring, use an ice-water bath to cool down until the internal temperature drops below 10°C, slowly add 2.2ml of concentrated sulfuric acid dropwise, after the dropwise addition, set the reaction temperature to 30°C, stop the reaction when the reaction solution is transparent. Slowly add the reaction solution into 1L of purified water (about 10 times the volume of the reaction solution) and stir to precipitate a fibrous precipitate (acetylated hyaluronic acid), then wash the precipitate with 1L, 0.5L and 0.5L of purified water for 3 times, After each wash, filter to dryness, add purified water to prepare about 3% solution and adjust pH to 5.8 with 2mol / L NaOH solution. After the acetylated hyaluronic acid solid is fully dissolved...

Embodiment 2

[0029] Weigh 3g of sodium hyaluronate powder with a molecular weight of 500 kDa, add it to a 250ml three-necked flask, use 30ml acetic acid and 120ml acetic anhydride (V 乙酸 :V 乙酸酐 = 1:4) as an acylation reagent and reaction solvent, under mechanical stirring, use an ice-water bath to cool down until the internal temperature drops below 10°C, slowly add 1.5ml of concentrated sulfuric acid dropwise, after the dropwise addition, set the reaction temperature to 5°C, stop the reaction when the reaction solution is transparent. Slowly add the reaction solution into 4L of purified water (about 20 times the volume of the reaction solution) and stir to precipitate a fibrous precipitate (acetylated hyaluronic acid), then wash the precipitate with 2L, 1L and 1L of purified water for 3 times, each time After washing, all were suction-filtered to dryness, and a 5% solution was prepared by adding purified water, and the pH was adjusted to 6.0 with 1mol / L NaOH solution. After the acetylate...

Embodiment 3

[0032] Weigh 10g of sodium hyaluronate powder with a molecular weight of 3000 kDa, add it to a 250ml three-necked flask, use 25ml acetic acid and 75ml acetic anhydride (V 乙酸 :V 乙酸酐 = 1:3) as an acylation reagent and reaction solvent, under mechanical stirring, use an ice-water bath to cool down until the internal temperature drops below 10°C, slowly add 5ml of concentrated sulfuric acid dropwise, after the dropwise addition, set the reaction temperature to 40 °C, stop the reaction when the reaction solution is nearly transparent. Slowly add the reaction solution into 0.2L of purified water (about 2 times the volume of the reaction solution) and stir to precipitate a fibrous precipitate (acetylated hyaluronic acid), then wash the precipitate with 1L, 1L and 1L of purified water for 3 times, each After washing for several times, they were suction filtered to dryness, and purified water was added to prepare about 8% solution, and the pH was adjusted to 6.8 with 1mol / L NaOH solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com