Microexpanded ultrahigh-performance concrete and preparation method

An ultra-high-performance, micro-expansion technology, which is applied in the field of highway bridge engineering and building materials, can solve the problems that the technical performance cannot fully meet its needs, the construction difficulty of ultra-high-performance concrete, and the shrinkage of ultra-high-performance concrete are large. No-steam curing construction, good construction performance, and improved flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of micro-expansion ultra-high performance concrete comprises the following steps:

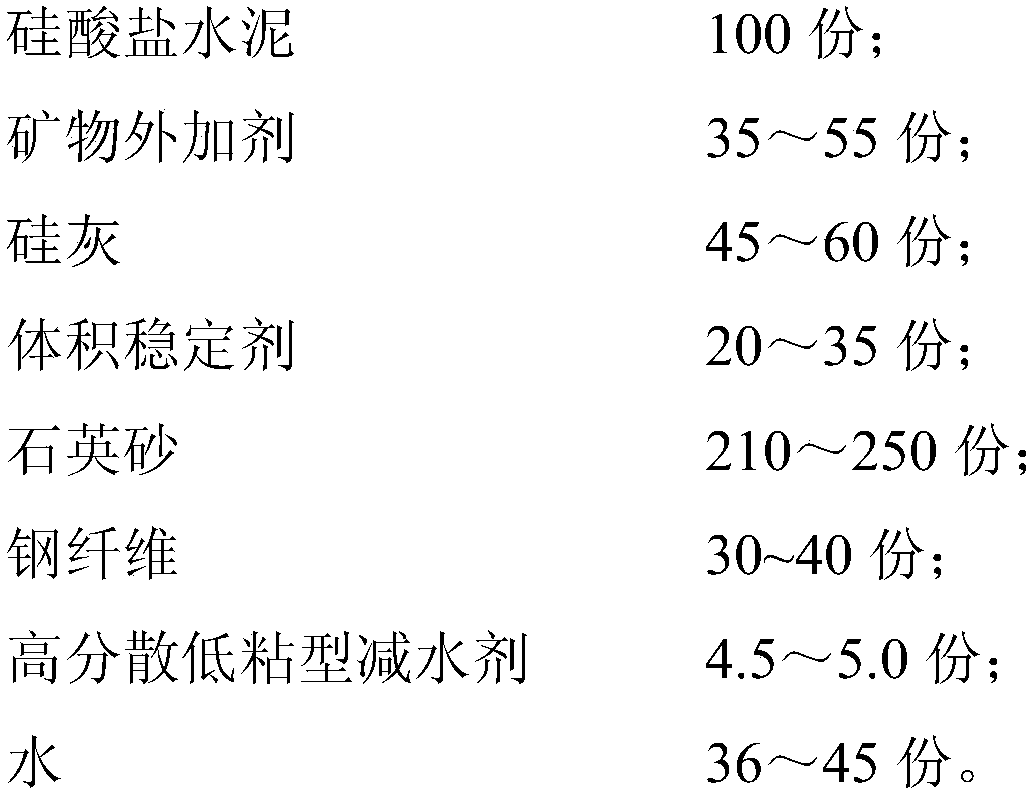

[0028] 1) According to the weight ratio of the raw material components, weigh the corresponding parts by weight of Portland cement, mineral admixture, silica fume, volume stabilizer, quartz sand, steel fiber, high-dispersion and low-viscosity water reducer and water ,spare. The raw materials are equipped as follows:

[0029] Portland cement is P.Ⅱ type Portland cement produced by Hubei Yadong Cement Co., Ltd., with a strength grade of 52.5 and a specific surface area of 435m 2 / kg, standard thick water requirement 29.8%, initial setting time 125min, final setting time 184min, 3d compressive strength and flexural strength were 32.0MPa and 5.6MPa, 28d compressive strength and flexural strength were 60.1MPa and 10.8 MPa.

[0030] The mineral admixture is compounded by fly ash, floating beads and finely ground limestone powder. The weight ratio is: fly ash: floati...

Embodiment 1~3 and comparative example 1~3

[0043] Examples 1-3 are micro-expansion ultra-high performance concrete prepared by using the raw materials and their corresponding component ratios and preparation methods described in the present invention. Comparative Example 1 uses the above-mentioned raw materials and preparation methods, but not prepared according to the ratio of the present invention The ultra-high performance concrete that forms, embodiment 1~3 and comparative example 1 are as shown in table 2 for each raw material component weight ratio ratio:

[0044] Table 2

[0045]

[0046] Comparative examples 2 to 3 are ultra-high performance concrete prepared by using conventional admixture fly ash (National Standard Class I fly ash) and ettringite and other materials. The weight ratio of each raw material component is shown in Table 3:

[0047] table 3

[0048]

[0049] The main performance parameters of the ultra-high performance concrete that each embodiment 1~3 and comparative examples 1~3 make in ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com