Compact turbid circulating water treatment station

A technology for turbid ring water and treatment stations, which is applied in water treatment parameter control, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of plate and frame filter press dehydration that can only run intermittently and plate and frame Difficult dehydration of the filter press, increase in the amount of dry sludge, etc., to achieve the effect of reducing the scale of sludge treatment, optimizing land occupation, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

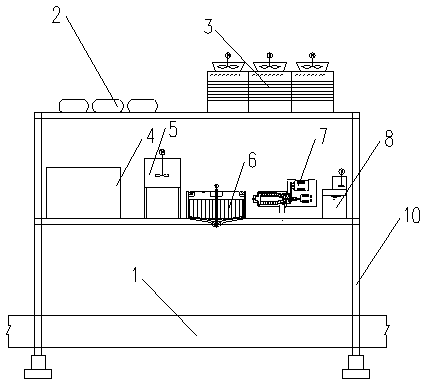

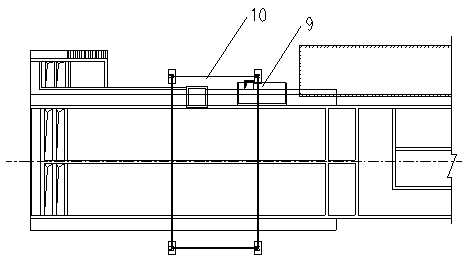

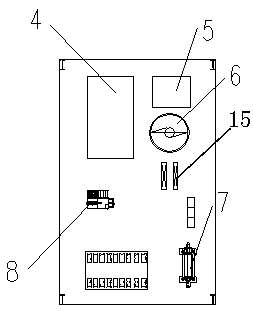

[0031] The following will combine figure 1 - Image 6 The compact turbid ring water treatment station provided by the present invention is described in detail, which is an available embodiment of the present invention, and it can be considered that those skilled in the art can modify and modify it within the scope of not changing the spirit and content of the present invention. polish.

[0032] A compact turbid ring water treatment station, which includes advection sedimentation tank 1, sand filter 2, cooling tower 3, cold water tank 4, sludge tank 5, sludge concentration tank 6, centrifugal dehydrator 7, dosing equipment 8, Sludge tank 9, station building frame 10, crane 11, electric valve 12, material level gauge 13, water pump system 14, sludge pump system 15, water point 16, proximity switch 17, the station building frame is arranged from top to bottom It has three floors, and the frame of the station building is made of reinforced concrete or steel structure; the advect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com