Spiral-wound membrane contactor and method used for treating ozone water

A contactor and roll-type membrane technology, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of the influence of the film-making process, application limitations, and low packing density of the plate-type membrane contactor. , to achieve the effect of promoting gas-liquid mass transfer, promoting ozone mass transfer, and promoting the development of membrane technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

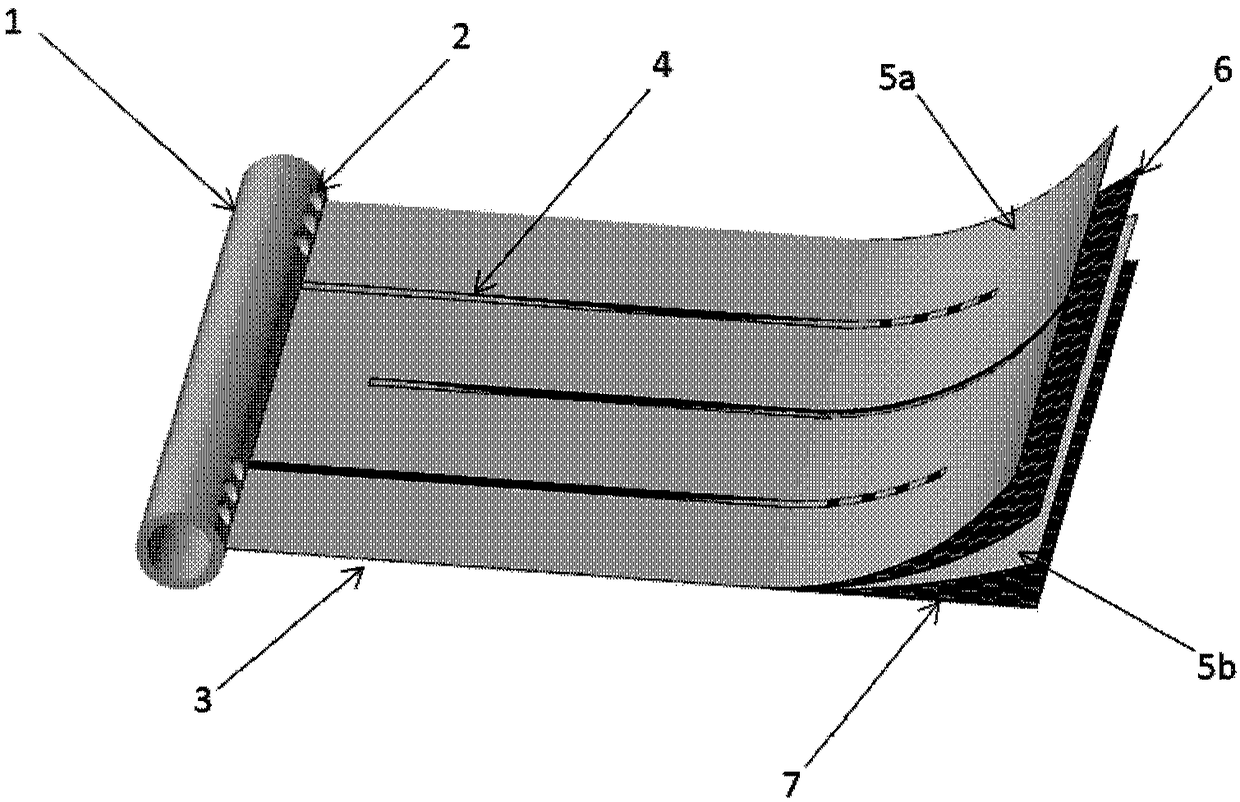

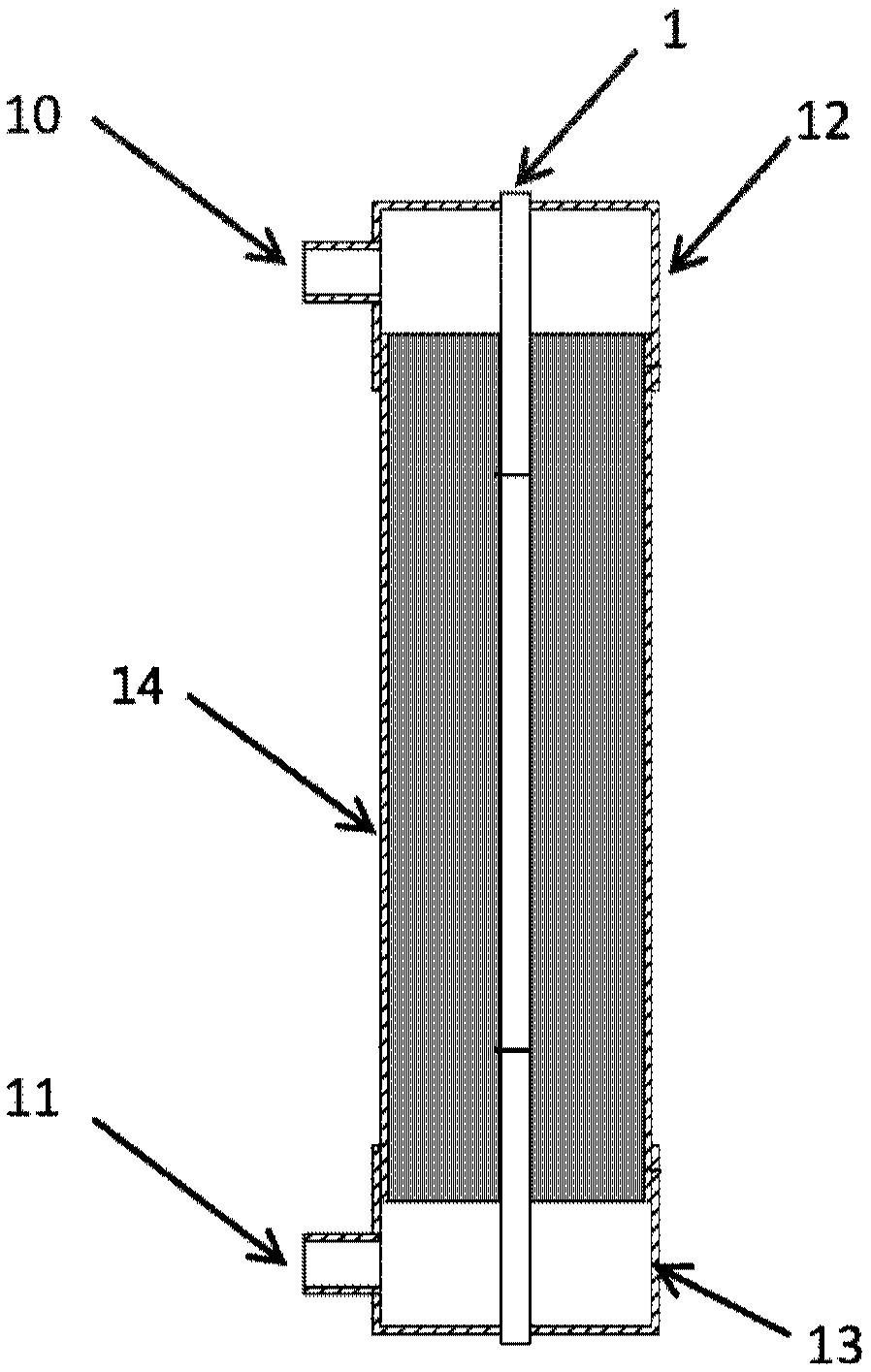

[0030] The invention discloses a roll-type membrane contactor and a method for ozone water treatment. A flexible plate-type membrane is rolled and packed in a membrane contactor shell to increase the filling density of membrane elements and promote the contact mass transfer efficiency of an ozone membrane.

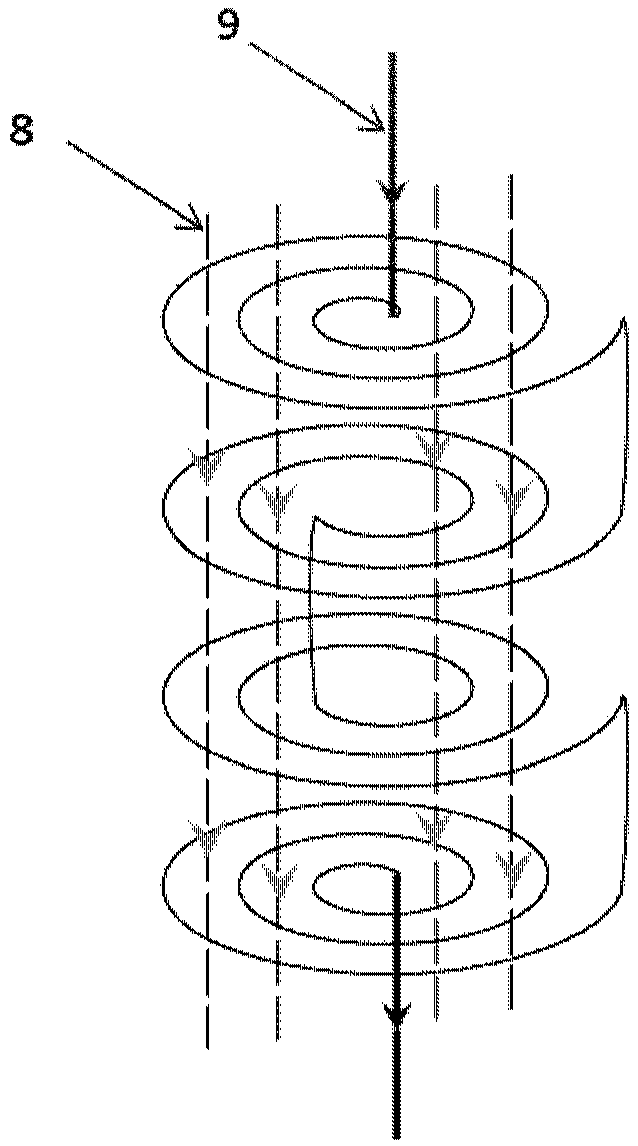

[0031] Specifically, as an exemplary embodiment, the present invention provides a roll-type membrane contactor for ozone water treatment, such as figure 1 and 3 As shown, it is a cylindrical structure, mainly including a central tube 1 and a membrane element 3, wherein: the two ends of the central tube 1 are respectively an air inlet end and an air outlet end, and the air inlet end and the air outlet end are not conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com