Fabric composite process

A composite process and fabric technology, applied in the direction of fabric surface trimming, lamination, layered products, etc., can solve the problems of poor adhesion of nylon composite fabrics, and achieve the effect of good adhesion, improvement of poor adhesion, and improvement of technical blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, this case is described in further detail.

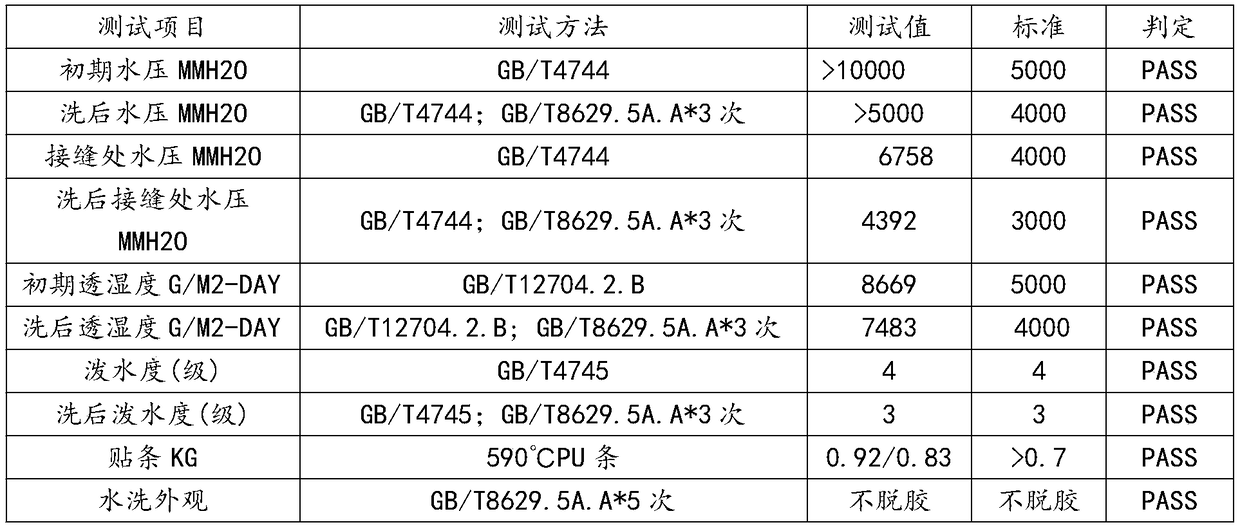

[0021] This case involves a fabric composite process that has passed the national standard for first-class jackets, mainly including the following process steps:

[0022] 1) Blank casting: choose nylon or polyester woven fabric;

[0023] For example, choose nylon 70D (FDY) * 160D (ATY) * 228T cloth;

[0024] 2) Desizing: Put the gray cloth into the desizing machine for desizing treatment;

[0025] Specifically, 7-slot tight continuous desizing and desizing machine can be used for desizing;

[0026] 3) Dyeing: dyeing the above-mentioned desized cloth through a dye vat;

[0027] Among them, adding auxiliary agents and acid dyes at room temperature, the dyeing temperature rise curve is 0.5°C / min to 80°C, then 1°C to 100°C, 100°C for 40 minutes, and 1°C to 70°C, take the cloth.

[0028] 4) Drying: Dry the dyed cloth through a tension-free dryer;

[0029] 5) Calendering: calenderi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com