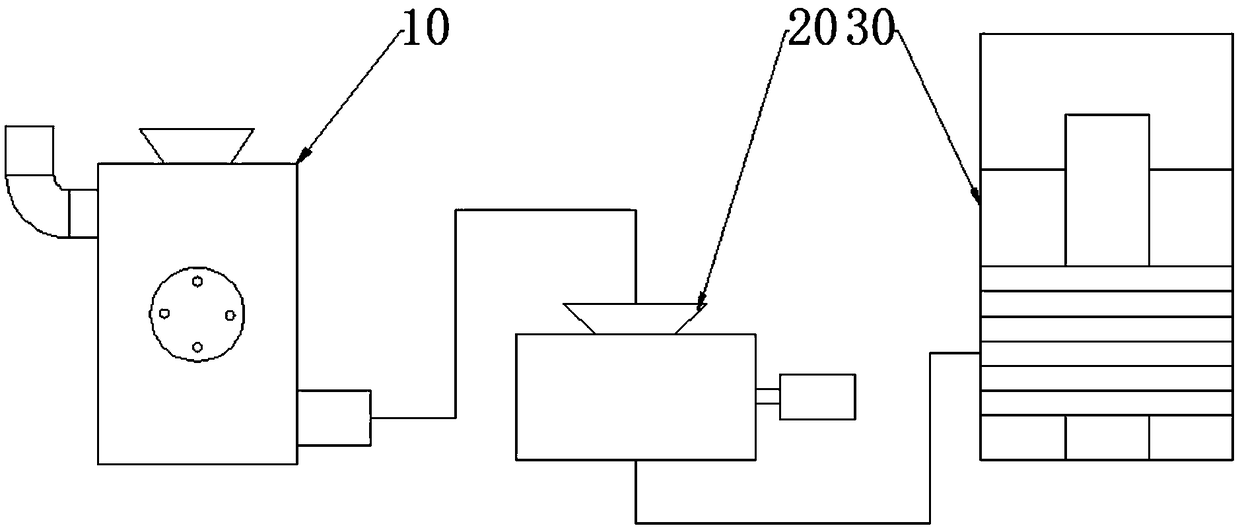

Partially fusible composite scrap recycling system

A compound and leftover technology, applied in recycling technology, plastic recycling, etc., can solve the problems of low separation purity, difficult reuse, high cost, etc., and achieve significant economic benefits, low use and maintenance costs, and small initial investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

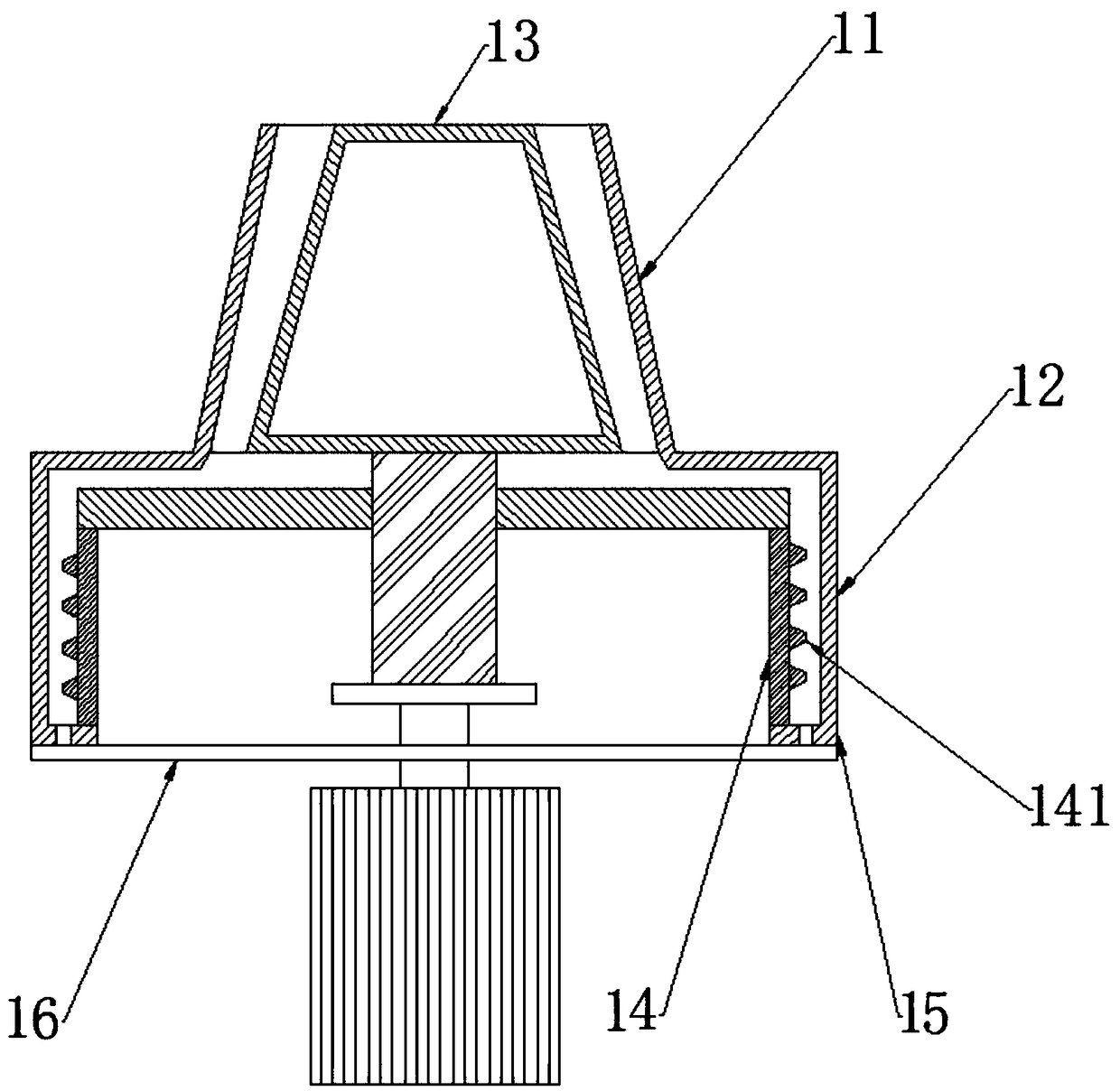

[0050] In a preferred embodiment, the granulation device is an extruder.

[0051] The system has recycled carpets and automotive interior scraps to produce hydrophobic floor tiles as an example. The specific production process includes the following steps:

[0052] 1) Use a crushing device to crush leftovers;

[0053] 2) Heating the leftover material until it partially melts to form a plastic body and make solid particles;

[0054] 3) Mix the solid particles and the adhesive evenly to form a coagulation;

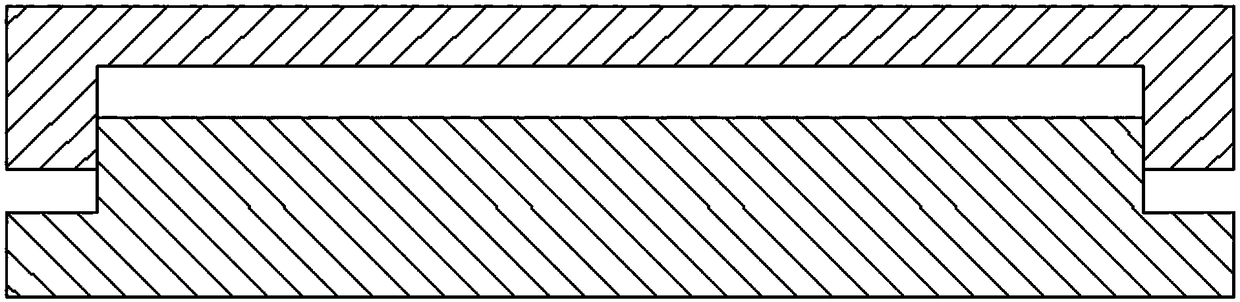

[0055] 4) Pour the concrete into the mold, pressurize until the adhesive hardens, and demould to obtain the finished product.

[0056] The usual crushing particle size of leftovers is in the range of 2-6mm. The meltable part is melted to form a plastic body. Of course, the meaning of melting does not necessarily require complete melting. For example, PP and PE, EVA materials have low melting points and low softening points, and have plasticity between the softening point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com