Busbar bending one-step molding controller and application method thereof

A technology of controller and stroke controller, which is applied in the field of busbar bending, can solve the problems of low accuracy rate, waste of finished busbar products, manual control of bending angle, etc., and achieve the effects of high accuracy rate, convenient operation and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

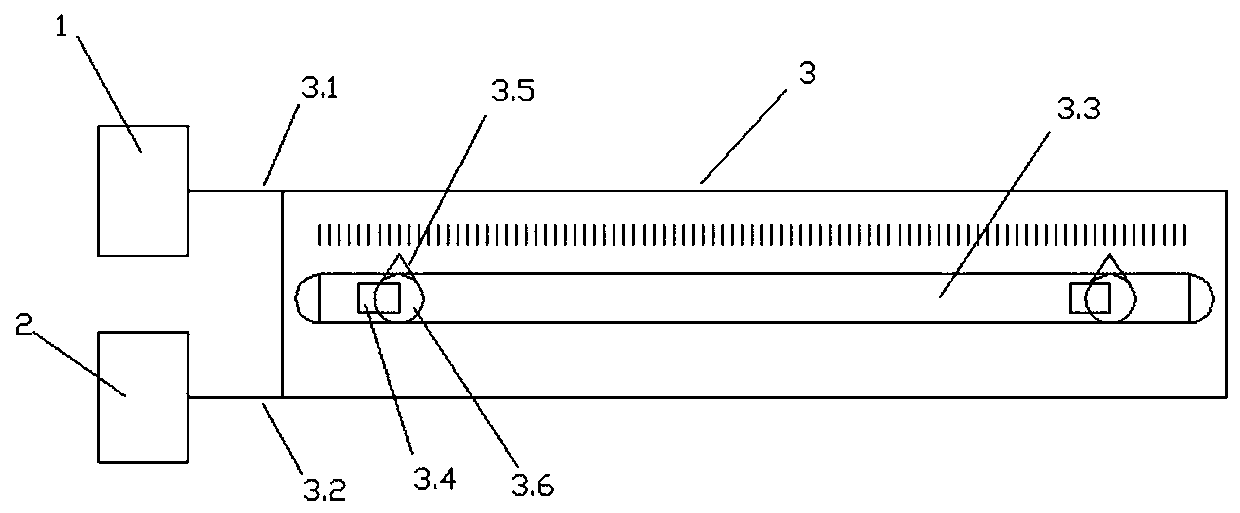

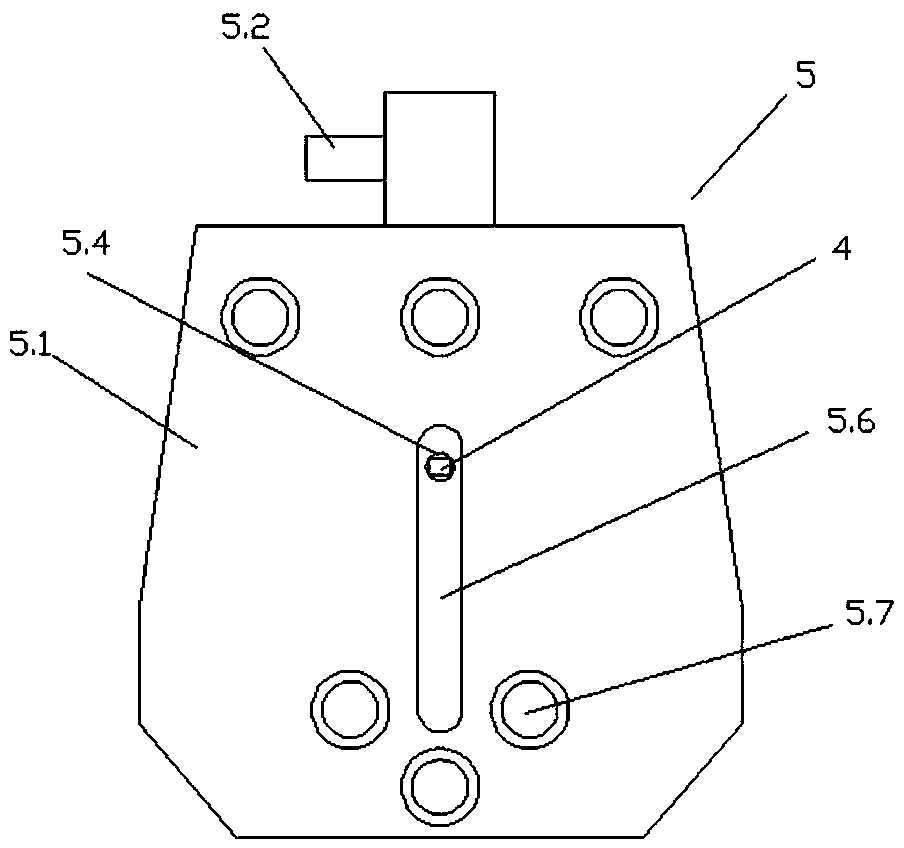

[0027] A busbar bending one-time forming controller mainly includes a voltage reducer 1, a relay 2, a stroke controller 3, an induction magnet 4 and a bending machine 5; the stroke controller 3 mainly includes an input terminal 3.1 and an output terminal 3.2 , a scale groove 3.3 and a sensor head 3.4, the sensor head 3.4 is fixed in the scale groove 3.3 by a screw 3.6, and a scale is provided above the scale groove 3.3; the bending machine 5 mainly includes a shell 5.1, a joint 5.2, Align the piston 5.3, bending upper die 5.4 and bending lower die 5.5, the center of the housing 5.1 is provided with a guide groove 5.6, the alignment piston 5.3 is connected to the center of the bending upper die 5.4, the bending The upper mold 5.4 is located above the bending lower mold 5.5, and the two are on the same vertical line. The two ends of the bending upper mold 5.4 are embedded in the guide groove 5.6; the pressure reducer 1 is installed at the input end 3.1 of the stroke controller 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com