Feed processing crushing equipment and using method thereof

A technology for crushing equipment and feed processing, applied in lighting and heating equipment, feed, cutting equipment, etc., can solve the problems of short service life of equipment, large crushing particle size, blocking work efficiency, etc., and achieve long service life and small crushing particle size. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

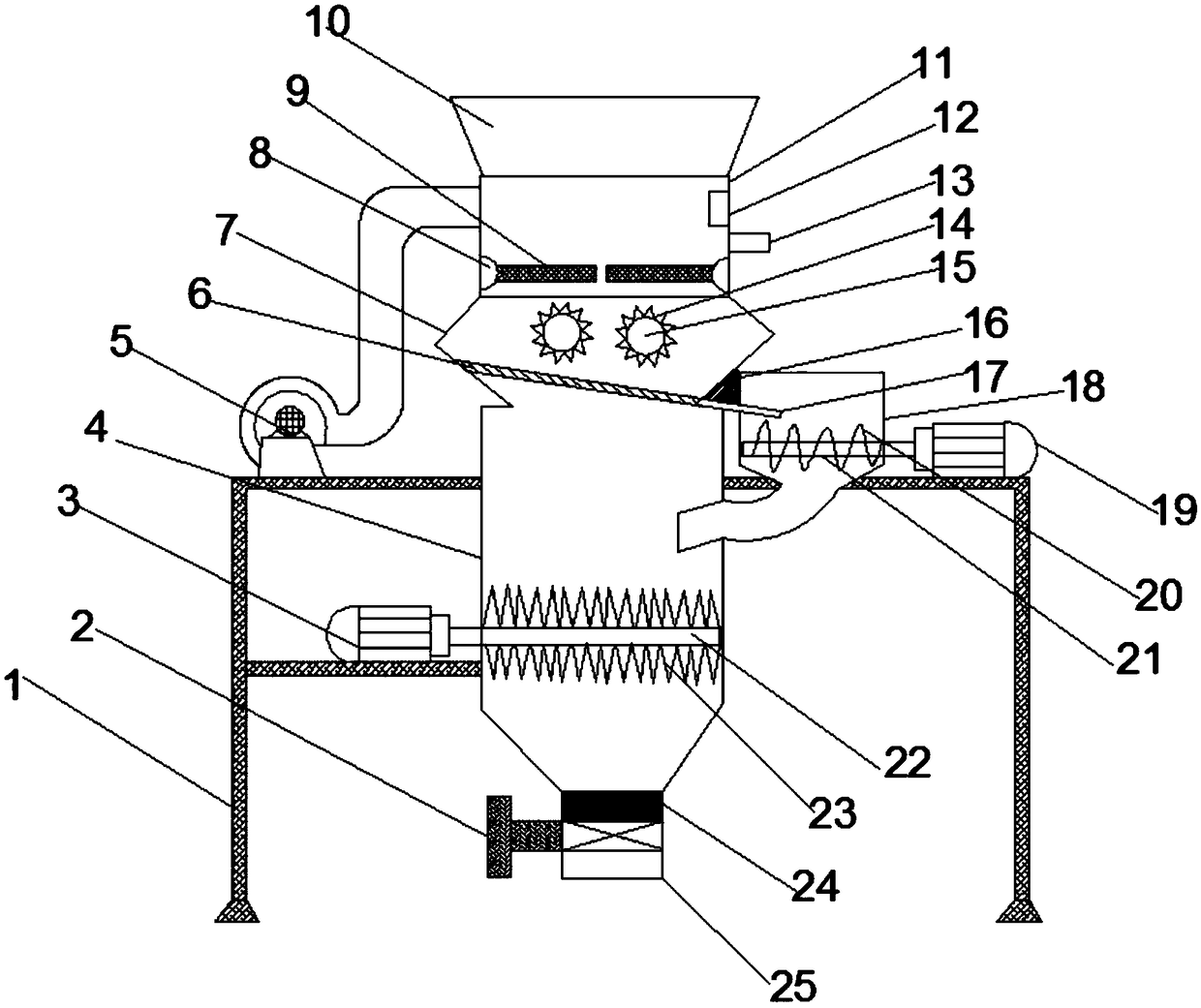

[0029] refer to figure 1 , a kind of feed processing and pulverizing equipment provided by the present invention comprises a support frame 1 and a pulverizer body connected to the support frame 1. The pulverizer body is sequentially connected with a feeding mechanism, a pulverizing mechanism, and a discharging mechanism from top to bottom. The mechanism includes a coarse crushing chamber 7 and a fine crushing chamber 4, the coarse crushing chamber 7 is connected with a coarse crushing assembly, the fine crushing chamber 4 is connected with a fine crushing assembly, and the coarse crushing chamber 7 and the fine crushing chamber 4 are connected through a filter screen 6 , the coarse crushing bin 7 near the filter screen 6 is connected with a secondary crushing bin 18, the secondary crushing bin 18 is connected with a secondary crushing assembly, and the secondary crushing bin 18 communicates with the fine crushing bin 4.

[0030] Working principle: When using the feed processin...

Embodiment 2

[0033] Based on Example 1, with reference to figure 1 , the coarse crushing assembly of this embodiment includes two coarse crushing rods 15 that are connected in the coarse crushing bin 7 and rotate relatively. Connected with drive mechanism one that drives coarse pulverizing stick 15 to rotate.

[0034] The coarse crushing roller is driven to rotate through the driving mechanism 1, thereby driving the coarse crushing tooth cutter 14 on the coarse crushing rod 15 to rotate, and the raw feed entering the coarse crushing bin 7 is coarsely crushed, wherein the coarse crushing tooth knife 14 is set at a different peak. In order to avoid the collision of the tooth cutters on the two rollers during the rotation of the coarse crushing roller 15; wherein the driving mechanism includes a motor, and the coarse crushing roller 15 is driven by the motor, and the coarse crushing roller 15 rotates stably. The coarse crushing assembly adopts the form of rotating the relatively arranged coa...

Embodiment 3

[0036] Based on Example 1, with reference to figure 1 , the fine crushing assembly of this embodiment includes a first rotating shaft 22 connected in the fine crushing bin 4, the first rotating shaft 22 extends to the outside of the fine crushing bin 4, and extends to the first rotating shaft 22 outside the fine crushing bin 4 A drive mechanism 2 3 that drives the first rotating shaft 22 to rotate is connected, and the first rotating shaft 22 is connected with a finely pulverized tooth cutter 23 .

[0037] The raw feed that has been pulverized by the coarse powder bin enters the fine powder bin, and the driving mechanism 23 drives the first rotating shaft 22 to rotate, thereby driving the finely pulverizing tooth cutter 23 on the first rotating shaft 22 to rotate, and the feed that enters the finely pulverizing bin The raw feed in 4 is crushed, and the crushed raw feed can be discharged into the collection device through the discharge mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com