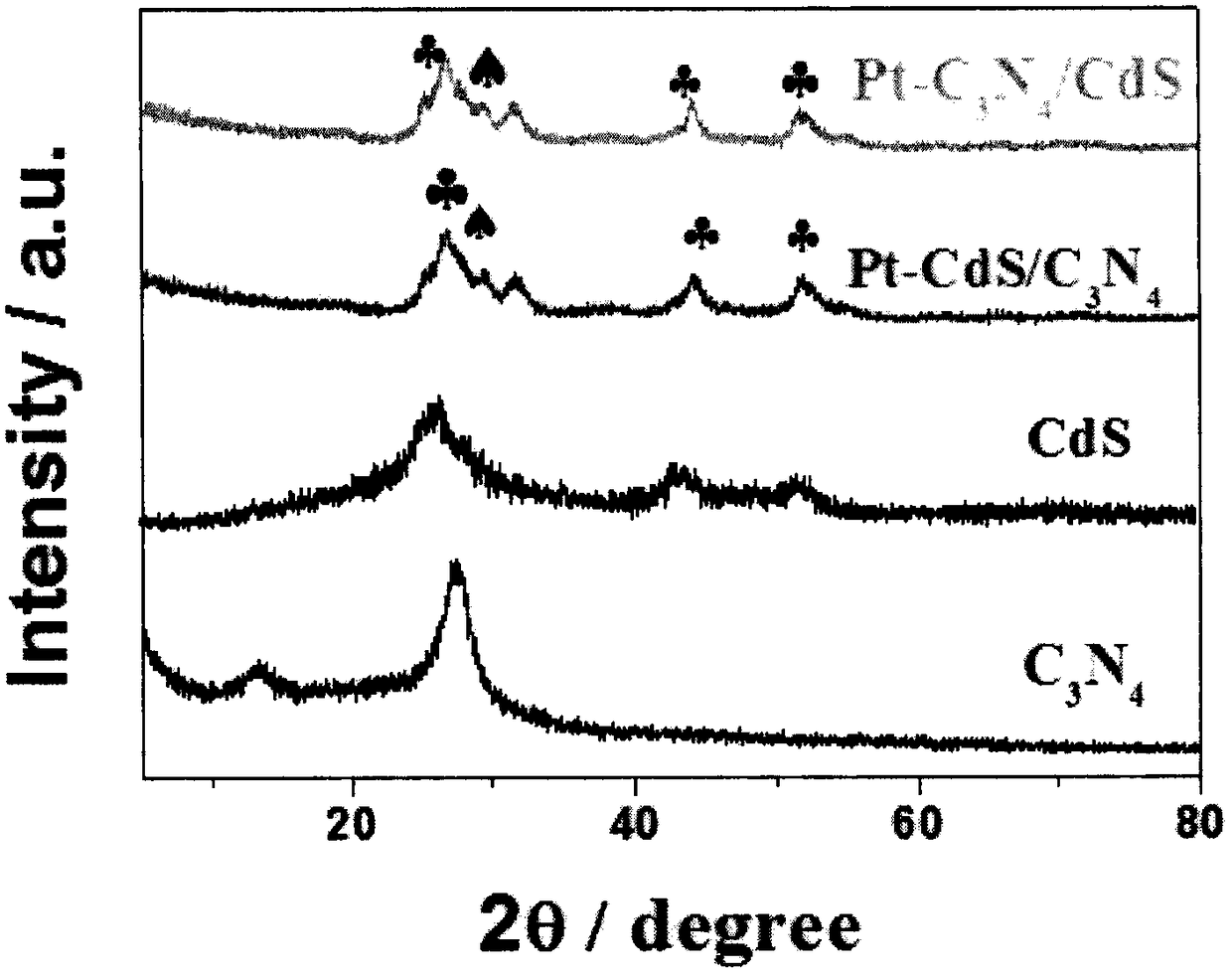

Preparation method of Z type heterojunction M-C3N4/CdS composite photocatalyst

A M-C3N4, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as complex synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A Z-type heterojunction M-C provided by the invention 3 N 4 / CdS composite photocatalyst preparation method, the preparation method includes the following steps:

[0045] 1) g-C 3 N 4 Preparation

[0046] Synthesis of nanoporous g-C using urea thermal polymerization method 3 N 4 ;

[0047] 2) M-C 3 N 4 Preparation

[0048] The g-C obtained in step 1) 3 N 4 Put the powder in a beaker, add deionized water, and ultrasonically disperse it evenly, put it into the photocatalytic reaction device, add the sacrificial agent solution in the beaker to obtain a mixed solution; then use a pipette to measure a certain amount of metal salt solution and add it In the mixed solution, a mixed solution 1 is obtained; under light, the mixed solution undergoes a reduction reaction to form metal particles and deposit on the gC 3 N 4 The surface, centrifuged, washed and dried to get M-C 3 N 4 ;

[0049] 3)M-C 3 N 4 / CdS synthesis

[0050] The M-C obtained in step 2) 3 N 4 , Add deionized water, ultraso...

Embodiment 1

[0073] Z-type heterojunction M-C provided by specific embodiments of the present invention 3 N 4 The preparation method of CdS / CdS composite photocatalyst includes the following steps:

[0074] 1) g-C 3 N 4 Preparation

[0075] Weigh 10g of urea, put it into a crucible, and sinter it in a muffle furnace at 500°C for 3h to obtain nanoporous g-C 3 N 4 ;

[0076] 2) Pt-C 3 N 4 Preparation

[0077] The g-C obtained in step 1) 3 N 4 The powder is placed in a beaker, 10ml of deionized water is added, and after the ultrasonic dispersion is uniform, it is placed in the photocatalytic reaction device, 2ml of methanol is added as a sacrificial agent solution in the beaker, and then 20 microliters of chloroplatinic acid is measured with a pipette. In the above mixture, platinum metal accounts for gC 3 N 4 The mass percentage of the powder is 5%, the concentration of the aqueous solution of chloroplatinic acid is 270mg / ml, and the mixed solution 1 is obtained; when the mixed solution undergoes a ...

Embodiment 2

[0091] In this embodiment, the chloroplatinic acid in step 2) is replaced with chloroauric acid, and the metal particles Au are deposited on g-C 3 N 4 The surface, after centrifugal washing and drying, get Au-C 3 N 4 The other method steps are the same as in Embodiment 1, and will not be repeated here.

[0092] In this embodiment, the method of light deposition is used in g-C 3 N 4 The metal promoter Au was deposited on the surface of the slab, and then CdS quantum dots were grown in situ on the surface by chemical bath deposition to synthesize Au-C 3 N 4 / CdS.

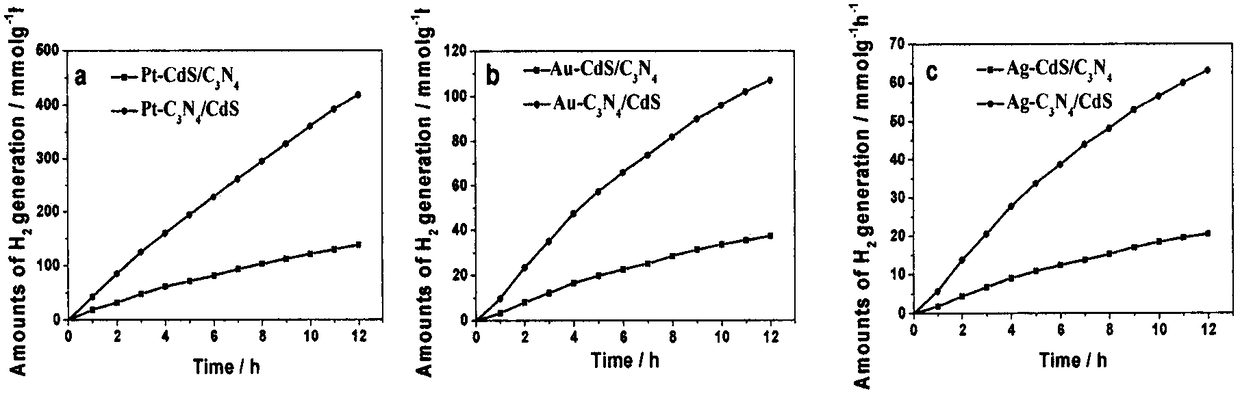

[0093] The prepared Z-type heterojunction Au-C 3 N 4 / CdS composite photocatalyst was used as the material for photolysis of water to produce hydrogen to test its photocatalytic performance. The specific method is the same as that in Example 1. The Au-C prepared in this example 3 N 4 The hydrogen production of CdS / CdS composite photocatalyst under 12h illumination is made into a curve, such as image 3 Figure b in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com