Packaging material for batteries, method for producing same and battery

A technology for packaging materials and batteries, which is applied to battery components, chemical instruments and methods, circuits, etc., and can solve problems such as unevenness, reduced formability of battery packaging materials, and poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

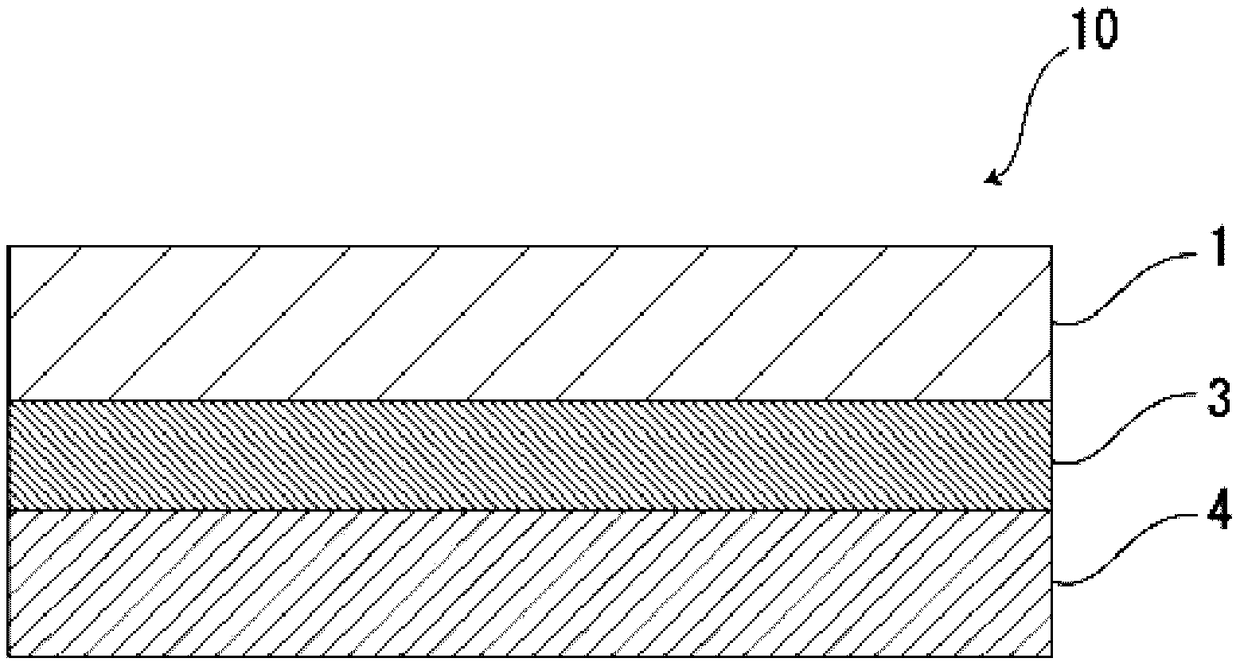

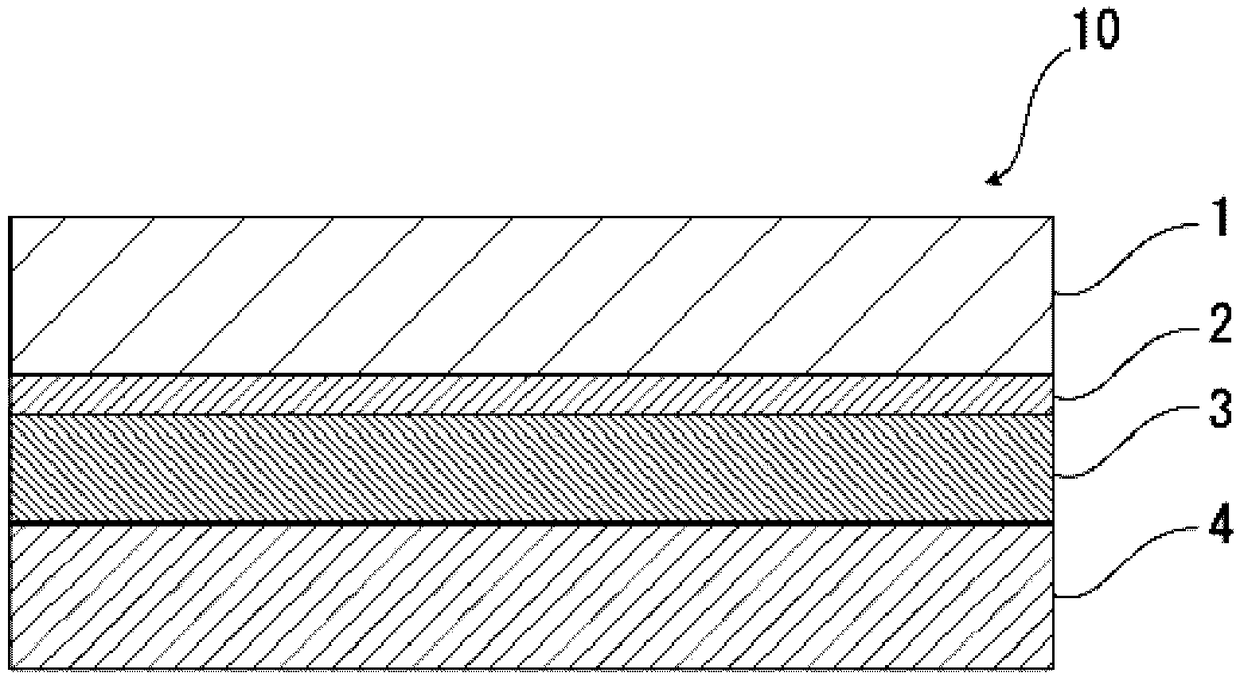

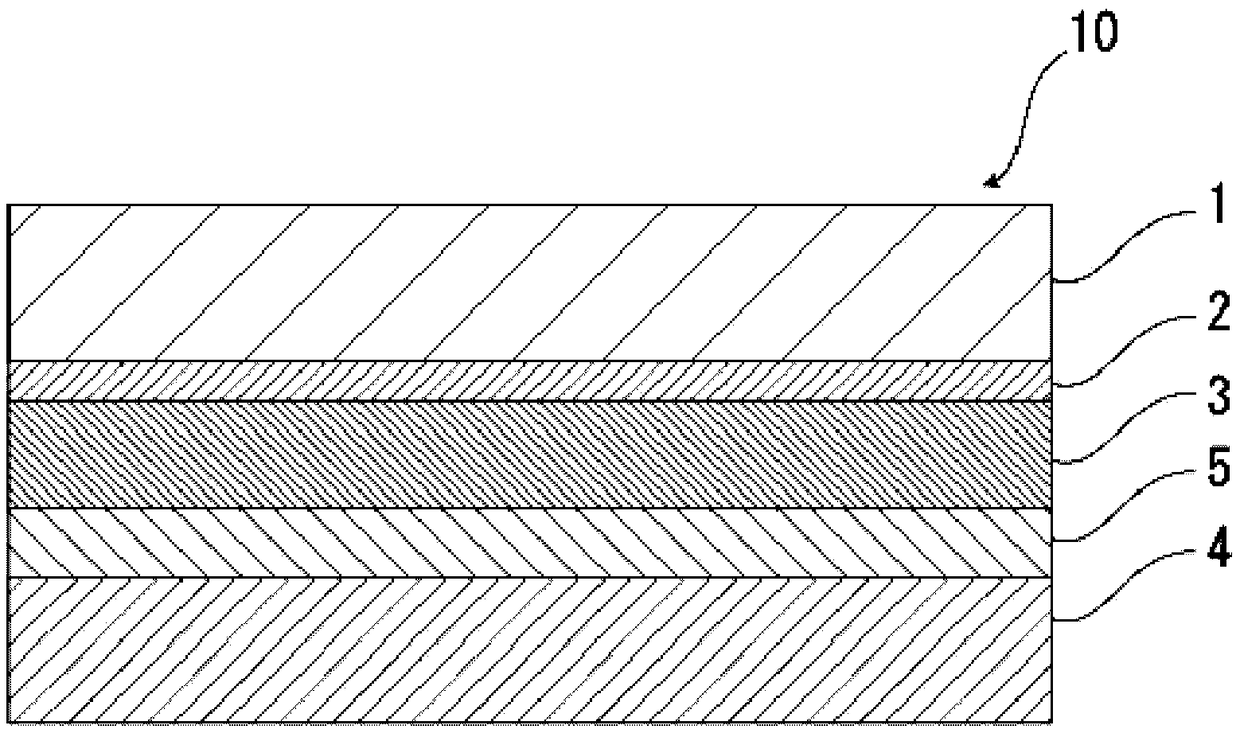

Image

Examples

Embodiment 1-10 and comparative example 1-9

[0144]

[0145] Aluminum foil (JIS H 4000: 2014A8021P- O, thickness 40μm) constitute the barrier layer. Specifically, a two-component polyurethane adhesive (polyol compound and aromatic isocyanate compound) was applied to one surface of the aluminum foil to form an adhesive layer (thickness: 3 μm) on the barrier layer. Next, after laminating the adhesive layer on the barrier layer and the base layer, aging treatment is performed to produce a laminate of base material layer / adhesive layer / barrier layer. Among them, the chemical surface treatment of the aluminum foil used as a barrier layer is carried out by the following operation: using the roller coating method, the coating amount of chromium on both sides of the aluminum foil reaches 10mg / m 2 (dry mass) was coated with a treatment liquid composed of phenolic resin, chromium fluoride compound, and phosphoric acid, and baked.

[0146] Among them, in Table 1, Ny means nylon, PET means polyethylene terephthalate, PBT means p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com