Dip-coating technology for hardening film of anti-blue ray resin lens surface

A resin lens and hard coating technology, applied in optics, coatings, optical components, etc., can solve the problems of complicated preparation process, slowing down blue light, complicated operation, etc., and achieve the effect of simple preparation process, convenient operation, and filtering blue light radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

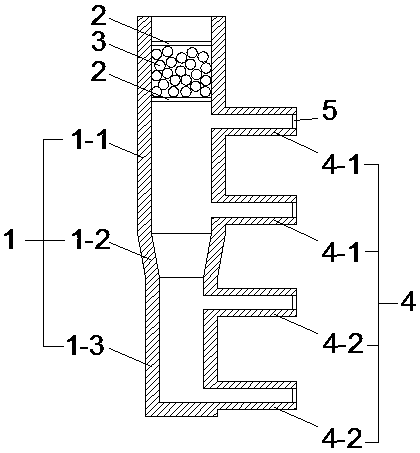

[0038] A preparation method of a dip-coating process for adding a hard film on the surface of an anti-blue light resin lens, characterized in that it comprises the following steps:

[0039] (3) Put 45 parts of o-phenylphenylethoxyacrylate, 8 parts of ethyl silicate, 1 part of trimethylsilimidazole, and 18 parts of isopropanol into the mixer for stirring. The stirring time is 15 minutes, and the stirring rate is Be 155r / min, obtain primary mixed solution;

[0040](4) Put the primary mixture, 2 parts of zirconium dioxide, 4 parts of indium oxide, 0.05 parts of titanium dioxide, and 10 parts of deionized water into the mixer for stirring. The stirring time is 25 minutes, and the stirring speed is 165r / min. Membrane fluid.

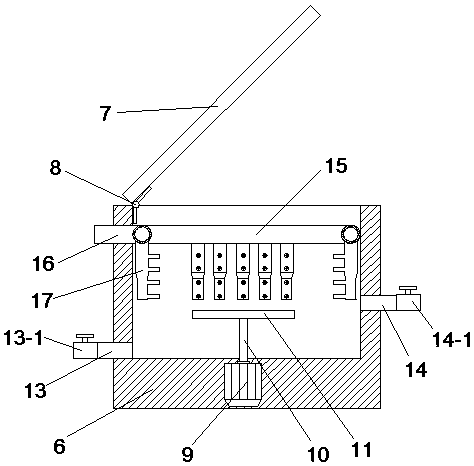

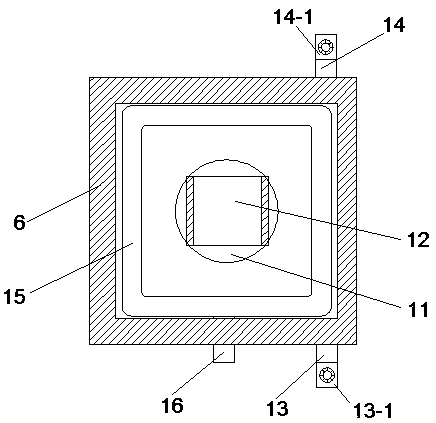

[0041] A kind of dip coating method of the dip coating process of adding hard film on the surface of anti-blue light resin lens, it is characterized in that, comprises the following steps:

[0042] (1) Pre-treat the resin lens, now put the resin lens into th...

Embodiment 2

[0059] The preparation method of the dip-coating process of adding a hard film on the surface of a kind of anti-blue light resin lens described in Example 1 is different in that it comprises the following steps:

[0060] (1) Put 55 parts of o-phenylphenylethoxyacrylate, 15 parts of ethyl silicate, 5 parts of trimethylsilimidazole, and 25 parts of isopropanol into the mixer for stirring. The stirring time is 20 minutes, and the stirring rate is Be 200r / min, obtain primary mixed solution;

[0061] (2) Put the primary mixture, 8 parts of zirconium dioxide, 9 parts of indium oxide, 3 parts of titanium dioxide, and 15 parts of deionized water into the mixer for stirring. The stirring time is 40 minutes, and the stirring speed is 200r / min. Membrane fluid.

[0062] A kind of dip coating method of the dip coating process of adding hard film on the surface of anti-blue light resin lens, it is characterized in that, comprises the following steps:

[0063] (1) Pre-treat the resin lens,...

Embodiment 3

[0069] The dip-coating process of adding a hard film on the surface of a kind of anti-blue light resin lens described in Example 1 is different in that the preparation method includes the following steps:

[0070] (1) Put 48 parts of o-phenylphenylethoxyacrylate, 11 parts of ethyl silicate, 4 parts of trimethylsilimidazole, and 21 parts of isopropanol into the mixer for stirring. The stirring time is 18 minutes, and the stirring rate is Be 168r / min, obtain primary mixed solution;

[0071] (2) Put the primary mixture, 5 parts of zirconium dioxide, 7 parts of indium oxide, 2 parts of titanium dioxide, and 12 parts of deionized water into the mixer for stirring. The stirring time is 35 minutes, and the stirring rate is 185 r / min. Membrane fluid.

[0072] A kind of dip coating method of the dip coating process of adding hard film on the surface of anti-blue light resin lens, it is characterized in that, comprises the following steps:

[0073] (1) Pre-treat the resin lens, now pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com