a pt/g-c 3 n 4 Composite material, electrochemical sensor and preparation method and use thereof

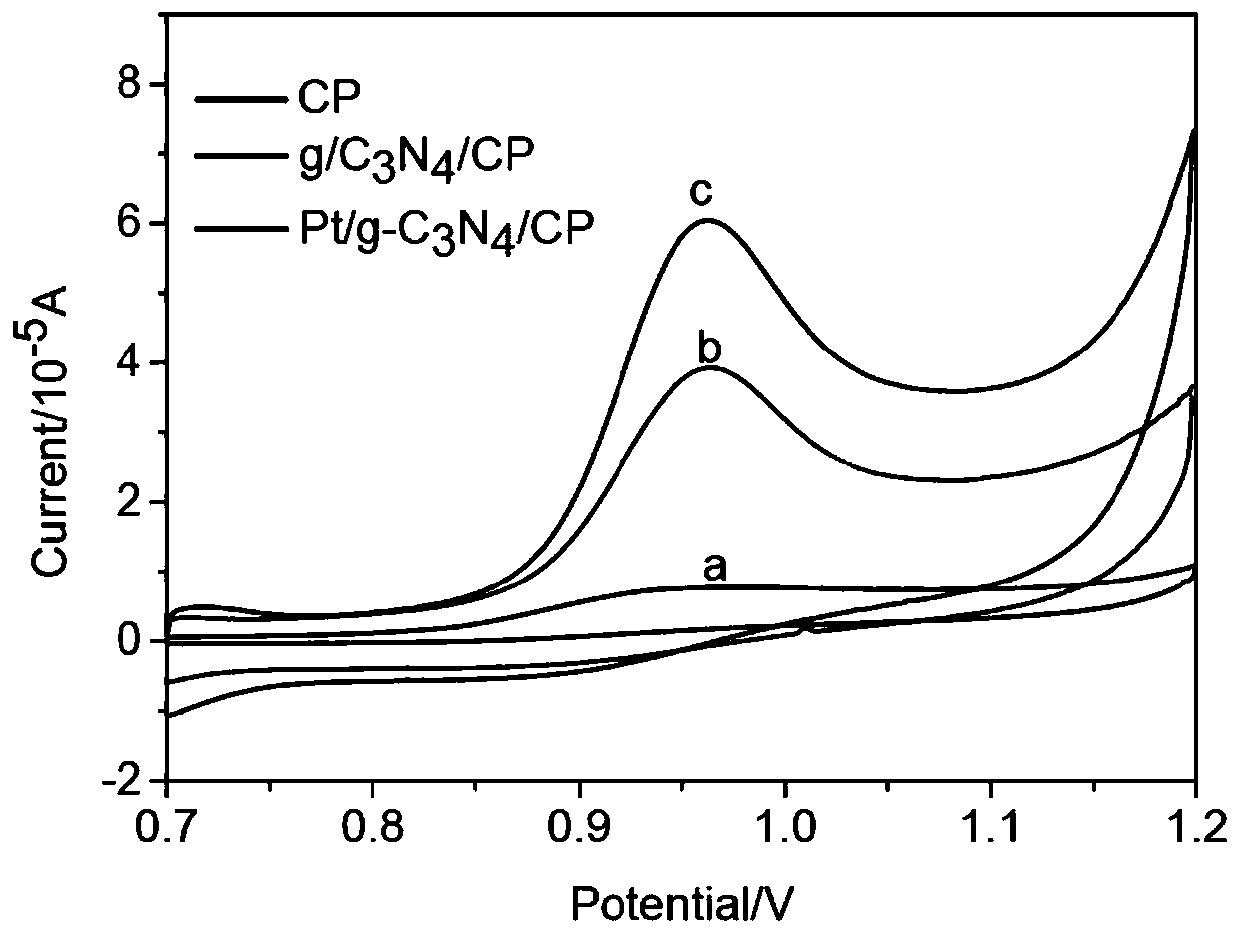

A composite material, g-c3n4 technology, applied in the field of Pt/g-C3N4 composite material, electrochemical sensor and its preparation, can solve the problem of no electrochemical response of phenol, and achieve good selectivity, high-efficiency electrochemical detection, high ratio The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

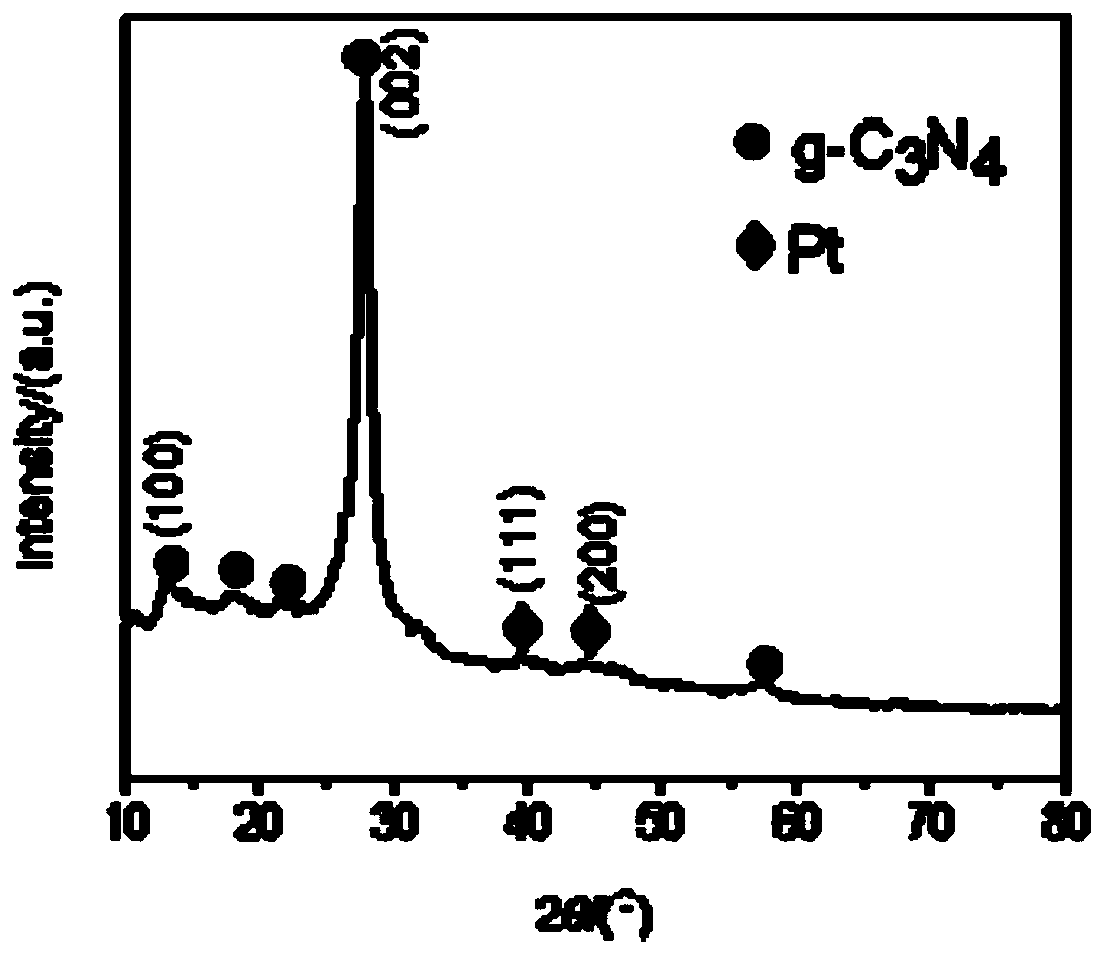

[0036] Example 1Pt / g-C 3 N 4 powder preparation

[0037] 1. Preparation of Carbon Nitride

[0038]Get 4g of melamine and put it into a mortar and grind it and put it into a crucible, ensure that there is a certain gap between the crucible and the lid, and then move it into the muffle furnace. Keep the temperature in the furnace at 520°C at a heating rate of 5°C / min, and calcinate for 4 hours. After the calcination is completed, it is naturally cooled to room temperature to obtain light yellow carbon nitride powder.

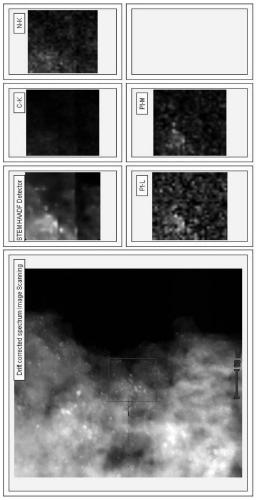

[0039] 2. Pt / g-C 3 N 4 Synthesis and powder preparation of

[0040] Get 50mg, the carbon nitride (g-C 3 N 4 ) powder was dissolved in 40mL of deionized water, ultrasonicated for 30min, and then within 15min, 0.3mL of chloroplatinic acid H 2 PtCl 6 ·6H 2 O (0.01M) was slowly added dropwise into the carbon nitride suspension, and continued to sonicate for 5 minutes to obtain a mixed suspension;

Embodiment 2

[0043] 1. Preparation of Carbon Nitride

[0044] Get 4g of melamine and put it into a mortar and grind it and put it into a crucible, ensure that there is a certain gap between the crucible and the lid, and then move it into the muffle furnace. Keep the temperature in the furnace at 520°C at a heating rate of 5°C / min, and calcinate for 4 hours. After the calcination is completed, it is naturally cooled to room temperature to obtain light yellow carbon nitride powder.

[0045] 2. Pt / g-C 3 N 4 Synthesis and powder preparation of

[0046] Get 0.2mol, carbon nitride (g-C 3 N 4 ) powder was dissolved in 50mL of deionized water, ultrasonic 25min, and then 0.5mL of chloroplatinic acid solution (1mmol H 2 PtC l6 ·6H 2 O configuration ) Slowly add it dropwise into the carbon nitride suspension, and continue to sonicate for 8 minutes to obtain a mixed suspension;

[0047] 0.2mol of anhydrous sodium citrate C 6 h 5 Na 3 o 7 Dissolve in 10mL of deionized water, then add it d...

Embodiment 3

[0049] 1. Preparation of Carbon Nitride

[0050] Get 4g of melamine and put it into a mortar and grind it and put it into a crucible, ensure that there is a certain gap between the crucible and the lid, and then move it into the muffle furnace. Keep the temperature in the furnace at 520°C at a heating rate of 5°C / min, and calcinate for 4 hours. After the calcination is completed, it is naturally cooled to room temperature to obtain light yellow carbon nitride powder.

[0051] 2. Pt / g-C 3 N 4 Synthesis and powder preparation of

[0052] Get 0.8mol, carbon nitride (g-C) of particle size 1-10 μm preparation 3 N 4 ) powder was dissolved in 100mL of deionized water, ultrasonic 35min, then 1mL chloroplatinic acid solution (5mmol H 2 PtC l6 ·6H 2 O configuration) is slowly added dropwise into the carbon nitride suspension, and continues to exceed 8min to obtain a mixed suspension; 0.5mol of anhydrous sodium citrate C 6 H5Na 3 o 7 Dissolve in 10mL of deionized water, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com