Temperature test method inside pole group during container formation period of lead-acid battery

A technology of lead-acid batteries and testing methods, applied in the direction of lead-acid batteries, lead-acid battery construction, thermometers, etc., can solve problems such as damage to battery structures, and achieve the effects of improving operating efficiency, avoiding damage, and high data consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

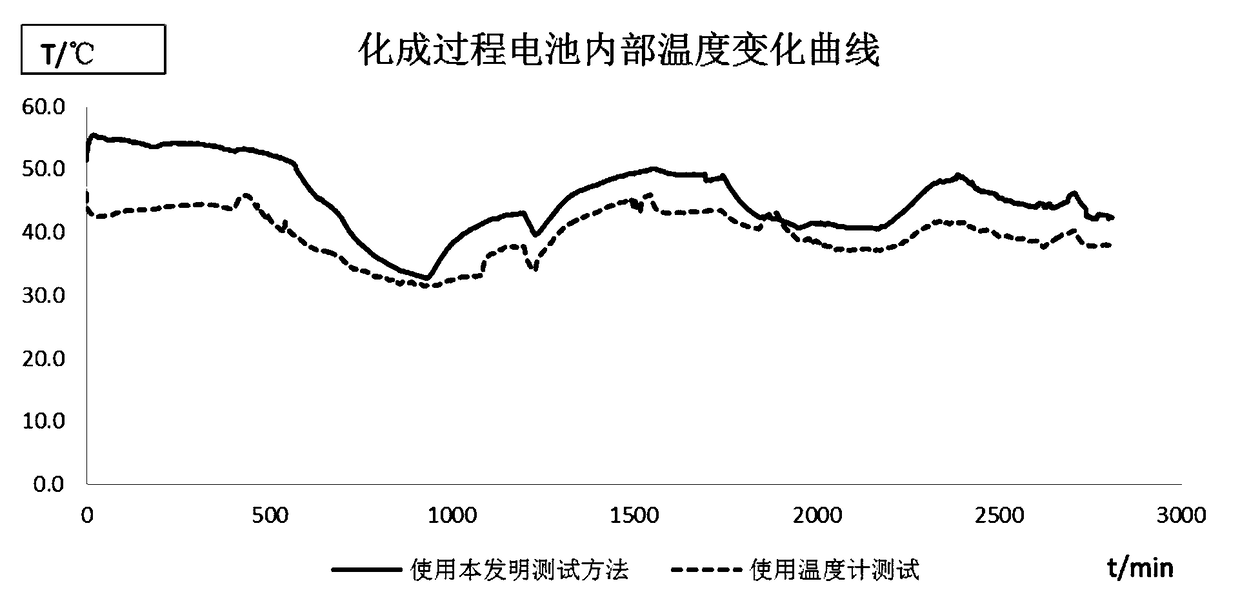

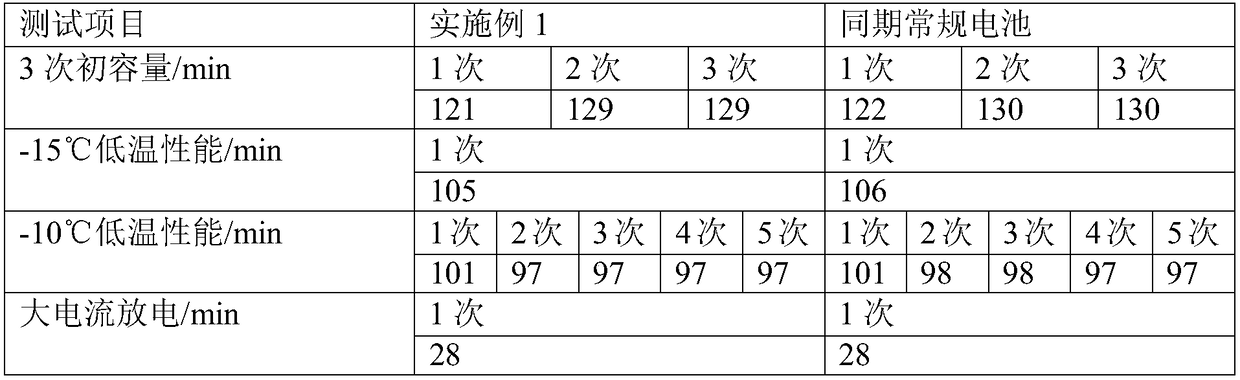

[0032] Perform electrode plate production and curing according to the normal production process of the battery; select a small positive grid, place the miniature temperature probe in the center of the grid and fix it; manually apply paste on the grid to obtain a wet plate; wet the plate with acid , Pass the pressure roller, solidify and dry; Wrap 5 conventional plates and 1 plate with temperature probe together to form 6 groups, the plate with temperature probe is located in the middle of the 6 groups; Enter the tank, cover, and add acid; all the processes of the grid must meet the process requirements of the conventional grid; turn on the wireless signal receiver to monitor the temperature change from the acid addition to the battery shelf formation until the battery is removed from the shelf. Curve see figure 1 , The battery performance data of the prepared battery is shown in Table 1.

[0033] Among them, the miniature temperature probe is 10mm long, 5mm wide, and 2mm thick. ...

Embodiment 2

[0039] Perform electrode plate production and curing according to the normal production process of the battery; select a small positive grid, place the miniature temperature probe in the center of the grid and fix it; manually apply paste on the grid to obtain a wet plate; wet the plate with acid , Pass the pressure roller, solidify and dry; Wrap 4 conventional plates and 2 plates with temperature probes together to obtain 6 groups, one plate with temperature probe is located in the middle of the 6 groups, and one is located The outermost of the 6 pole groups; insert the pole groups into the groove, cover, and add acid; all the grid processes need to meet the process requirements of the conventional grid; turn on the wireless signal receiver, you can monitor the battery from adding acid to the battery rack Formation, until the internal temperature change of the battery is off the shelf.

[0040] The miniature temperature probe is 10mm long, 5mm wide, and 2mm thick. It has acid an...

Embodiment 3

[0042] Except that the miniature temperature probe does not have a thin hook, the other measurement methods are completely the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com