Shell and tube heat exchanger

A heat exchanger, shell-and-tube technology, applied in the field of shell-and-tube heat exchangers, can solve problems such as single-function two-phase media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

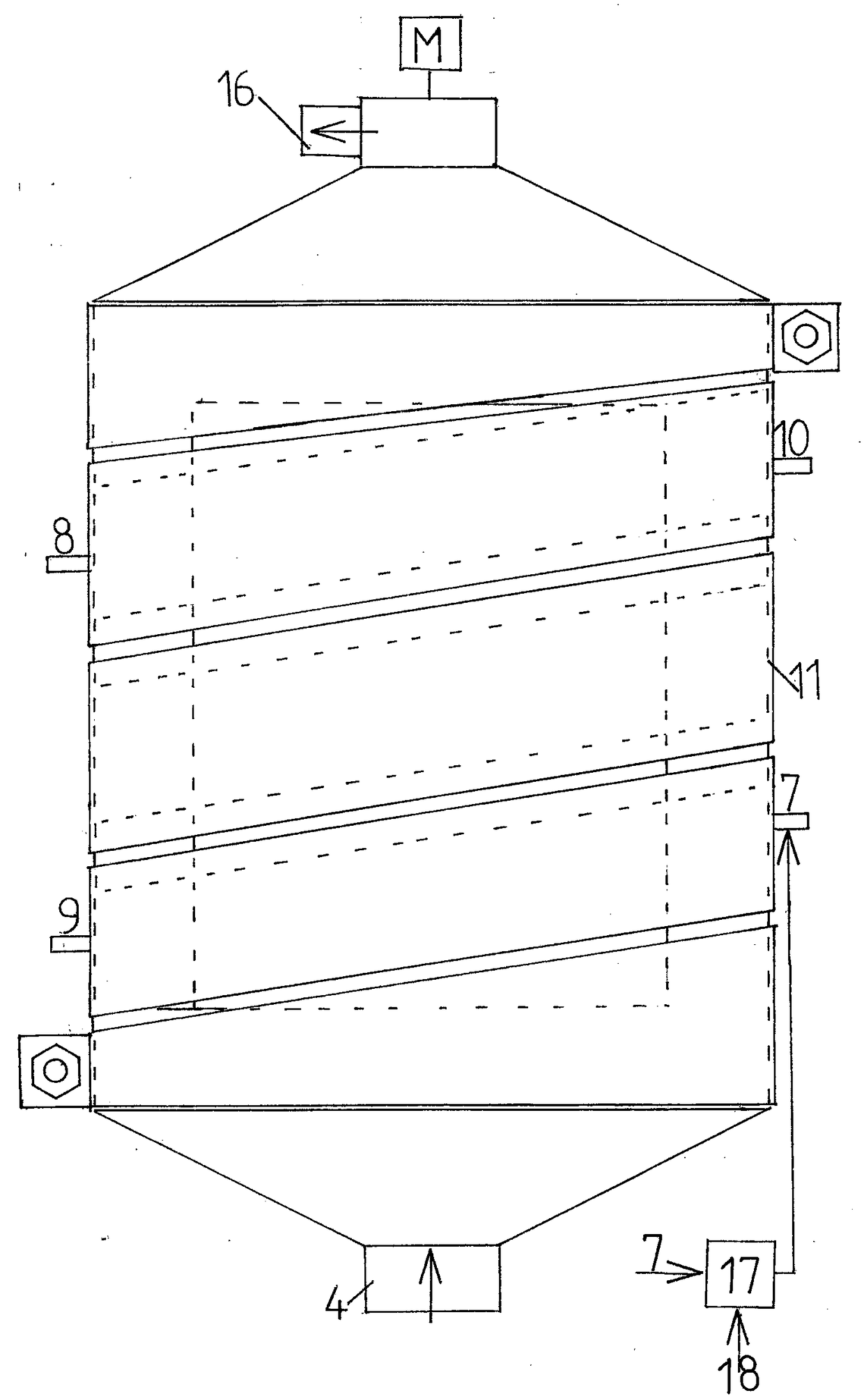

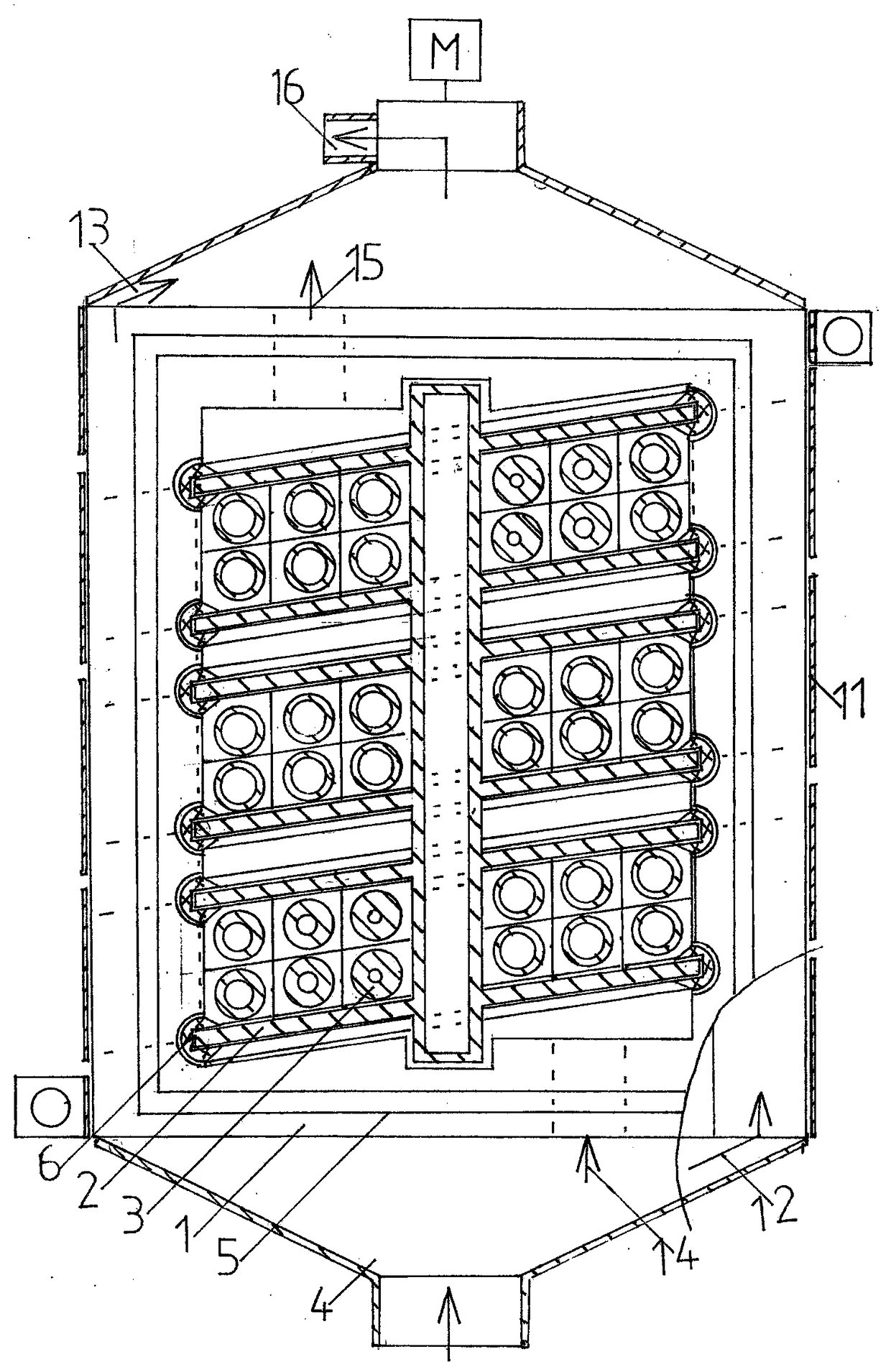

[0017] Such as figure 1 and figure 2 As shown, the spiral shell side 1) of the shell-and-tube heat exchanger in this embodiment, the double helix plate 2), the coil tube side 3), the spiral shell side air inlet 4, the shell side sealing groove 5, and the unilateral sealing line glue Quality sealing strip 6, shell side liquid medium inlet 7, shell side liquid medium outlet 8, tube side refrigerant inlet 9, tube side refrigerant outlet 10, steel spiral belt clamp 11, shell side outer spiral fin air inlet 12, shell side Outer helical fin heat exchange air outlet 13, double helix plate air inlet 14, double helix plate heat exchange air outlet 15, spiral shell side heat exchange air outlet 16, air-liquid medium automatic exchange valve 17, hot water level at the user end 18.

Embodiment 2

[0019] Install the spiral shell side sealing strip 5 on the half-side hollow semi-cylindrical rectangular plane of the spiral shell side 1, insert the outer side of the second-layer spiral plate of the double-helix plate 2 into the unilateral sealing line of the unilateral sealing line rubber sealing strip 6 and place the coil tube The tube pass 3 is installed on the corresponding spiral plate, and then the double helix plate 2 installed with the coil tube pass 3 is installed in the double helical groove corresponding to the half spiral shell pass 1, and the other half spiral shell pass 1 is installed to tighten the steel spiral belt clamp 11 Make the two hollow semicircular spiral shells into columns, install the air inlet 4 of the spiral shell and the heat exchange air outlet 16 of the spiral shell, connect the hot water level 18 at the user end to the automatic air-liquid interchange valve 17.

[0020] When using it specifically:

[0021] Connect the shell side liquid outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com