Reinforced heat transferring element

A technology to strengthen heat transfer and components, applied in tubular components, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of efficient utilization of resources, saving length and diameter, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

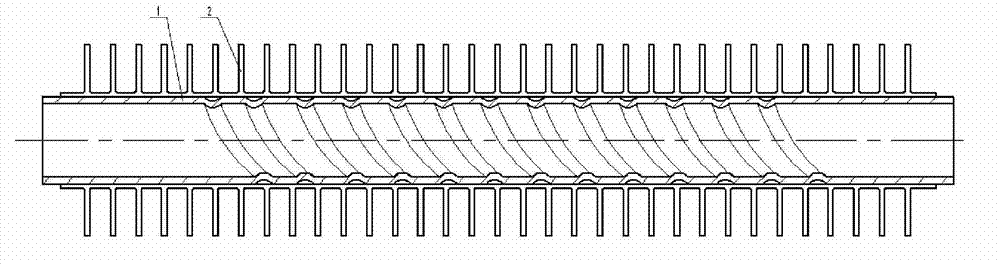

[0016] Embodiment one: if figure 1 As shown, an enhanced heat transfer element includes a light pipe 1, which is characterized in that: the light pipe 1 is covered with an integral aluminum-rolled finned tube 2; the light pipe 1 is a threaded pipe;

[0017] Taking the bare pipe 1 as the base pipe, the smooth pipe is first rolled to form a threaded pipe 1, and then the pipe is covered with aluminum rolled fins 2 to form a threaded aluminum rolled finned pipe. The technology of the invention is mainly used in the heat exchange process in which the fluid inside the tube is liquid and the fluid outside the tube is gas. The protrusion formed by rolling in the tube effectively destroys the boundary laminar flow, making the fluid appear as turbulent flow in any area in the tube, which obviously improves the heat exchange efficiency. The overall aluminum-rolled finned tube is set outside the tube, which expands the contact area between the fluid outside the tube and the heat exchange...

Embodiment 2

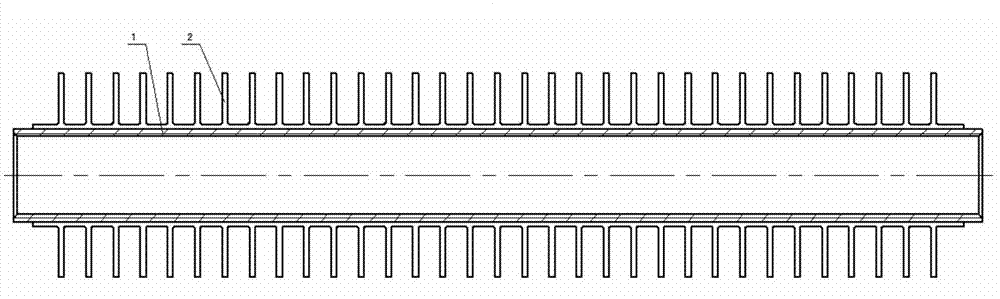

[0018] Embodiment 2: An enhanced heat transfer element, including a light pipe 1, such as figure 2 As shown: the light pipe 1 is sheathed with an integral aluminum-rolled finned pipe 2; the light pipe 1 is processed into a continuous internal thread.

[0019] Such as figure 2 As shown, the technical solution adopted by the technology of the present invention to solve its technical problems is: use the bare pipe 1 as the base pipe, process continuous internal threads in the pipe 1 to make an internally threaded pipe, add aluminum rolled fins 2 outside the pipe, Formed internally threaded aluminum rolled finned tubes. The technology of the invention is mainly used in the heat exchange process in which the fluid inside the tube is liquid and the fluid outside the tube is gas. The continuous thread in the tube effectively destroys the boundary laminar flow, making the fluid appear as turbulent flow in any area in the tube, which obviously improves the heat exchange efficiency....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com