High-finishing degree waterproof molded pulp product and preparation process thereof

A technology of pulp molding and high finish, applied in the direction of non-woody plant/crop pulp, paper, papermaking, etc., can solve the problem of color, color uniformity, color fastness and hygienic safety requirements, pure color paper mold packaging High demand for products and other issues, to achieve the effect of rapid growth and strong regeneration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation process of a high-gloss waterproof pulp molded product of the present embodiment comprises the following steps:

[0028] S1. Decompose and grind the original bamboo in boiling water for 1 hour to obtain bamboo fiber, select 200-400 mesh bamboo fiber, add water twice the weight of bamboo fiber and stir into bamboo fiber slurry;

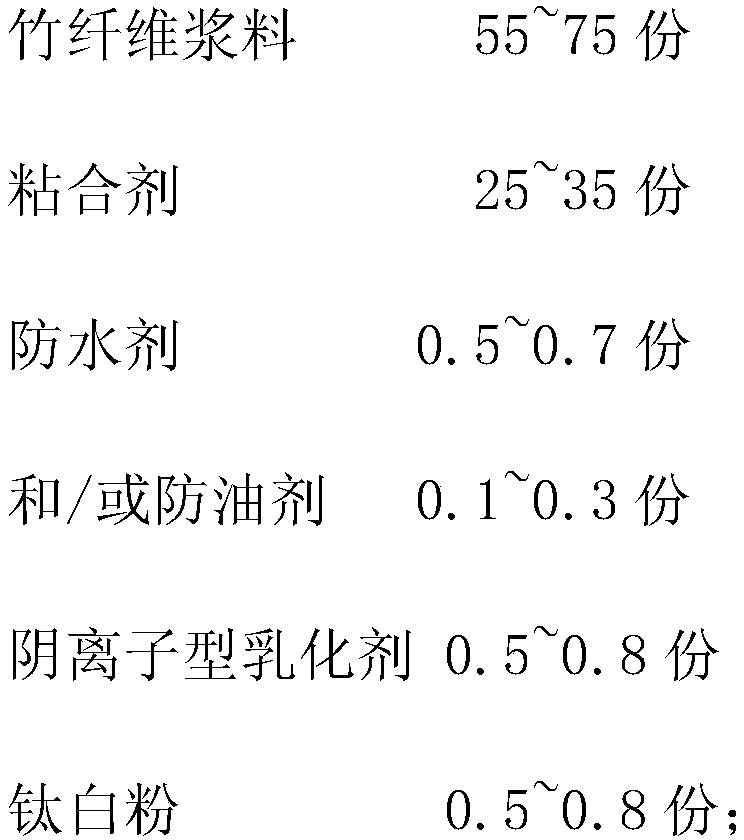

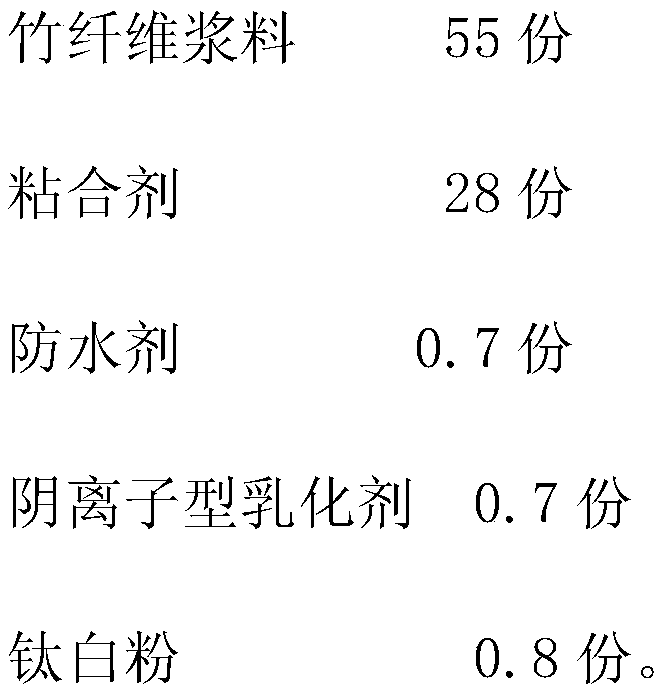

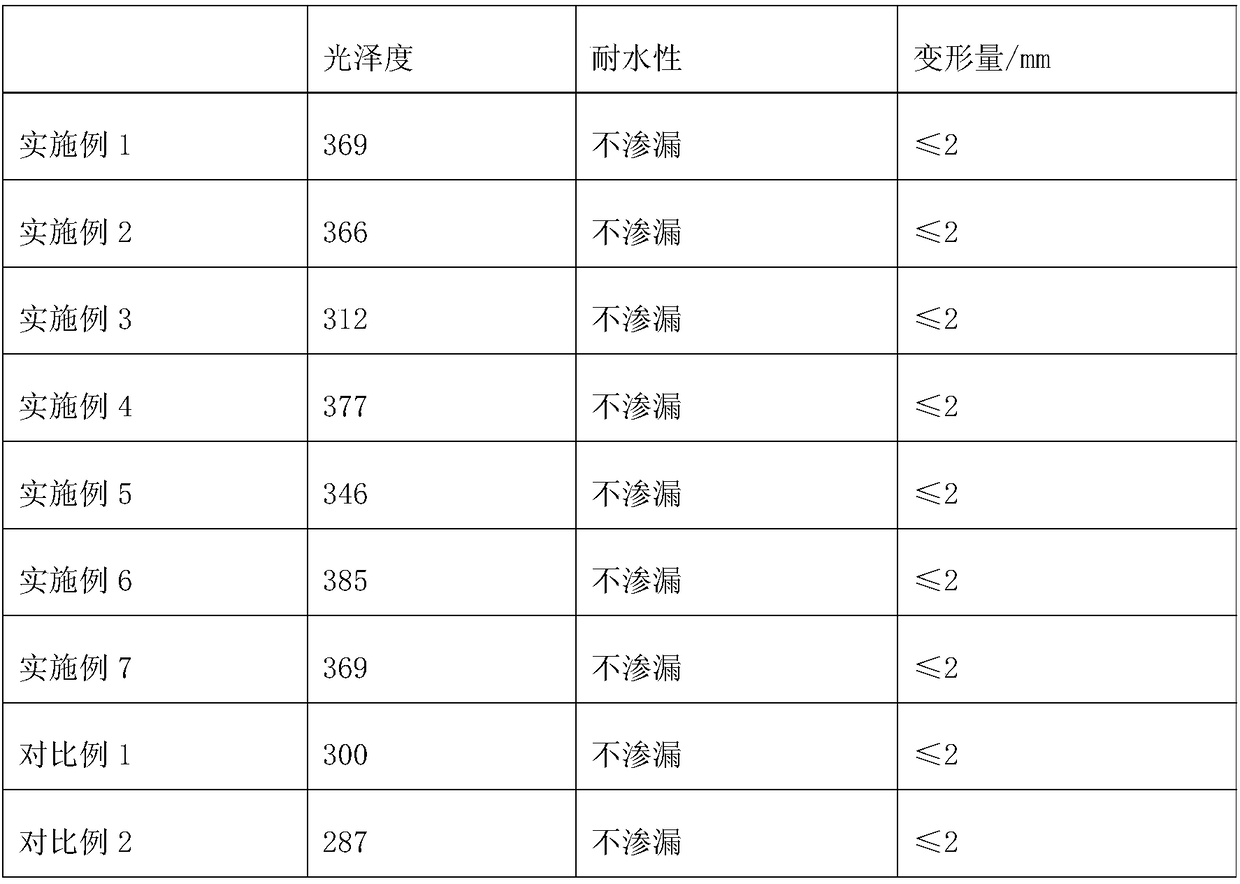

[0029] S2. Take 55 parts of the above-mentioned bamboo fiber slurry, add 35 parts of binder, 0.5 part of water repellent, 0.3 part of oil repellent, 0.5 part of anionic emulsifier, and 0.8 part of titanium dioxide in order to be placed in the crushing tank Mix at a speed of 500-600 rpm for 8-15 minutes until evenly mixed;

[0030] Among them, the adhesive selected in this embodiment is prepared by mixing water, carboxymethyl cellulose, and starch in parts by weight of 1:1:2; the water repellant is acrylate copolymer, and the oil repellent is acrylate polymer Polymer, anionic emulsifier dimethylol propionic acid and dimethylol buty...

Embodiment 2

[0033] A preparation process of a high-gloss waterproof pulp molded product of the present embodiment comprises the following steps:

[0034] S1. Decomposing and grinding the raw bamboo in boiling water for 2 hours to obtain bamboo fibers, selecting 200-400 mesh bamboo fibers, adding water 3 times the weight of the bamboo fibers and stirring to form a bamboo fiber slurry;

[0035] S2. Take 75 parts of the above-mentioned bamboo fiber slurry, add 25 parts of binder, 0.7 part of water repellent, 0.1 part of oil repellent, 0.8 part of anionic emulsifier, and 0.5 part of titanium dioxide in order to be placed in the crushing tank Mix at a speed of 500-600 rpm for 8-15 minutes until evenly mixed;

[0036] Among them, the adhesive selected in this embodiment is prepared by mixing water, carboxymethyl cellulose, and starch in a weight ratio of 1:2:1; the water repellent is acrylate copolymer, and the oil repellent is acrylate polymer polymer, anionic emulsifier dimethylolpropionic a...

Embodiment 3

[0039] A preparation process of a high-gloss waterproof pulp molded product of the present embodiment comprises the following steps:

[0040] S1. Decomposing and grinding the original bamboo in boiling water for 1.5 hours to obtain bamboo fibers, selecting 200-400 mesh bamboo fibers, adding water 2.5 times the weight of the bamboo fibers and stirring to form a bamboo fiber slurry;

[0041]S2. Take 60 parts of the above-mentioned bamboo fiber slurry, add 34 parts of adhesive, 0.6 part of water repellent, 0.2 part of oil repellent, 0.6 part of anionic emulsifier, 0.7 part of titanium dioxide and place them in the disintegration tank in sequence Mix at a speed of 500-600 rpm for 8-15 minutes until evenly mixed;

[0042] Among them, the adhesive selected in this embodiment is prepared by mixing water, carboxymethyl cellulose, and starch in parts by weight of 1:1.2:1.8; Molecular polymer, anionic emulsifier dimethylol butyric acid;

[0043] S3. Extend a part of the molding machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com