A kind of long-acting water-based antirust agent and preparation method thereof

A water-based anti-rust agent, long-acting technology, applied in the field of iron and steel anti-rust, can solve the problems of anti-rust agent stability and less attention to cleaning performance, to achieve excellent anti-humidity and anti-salt spray ability, long anti-rust period , the effect of not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

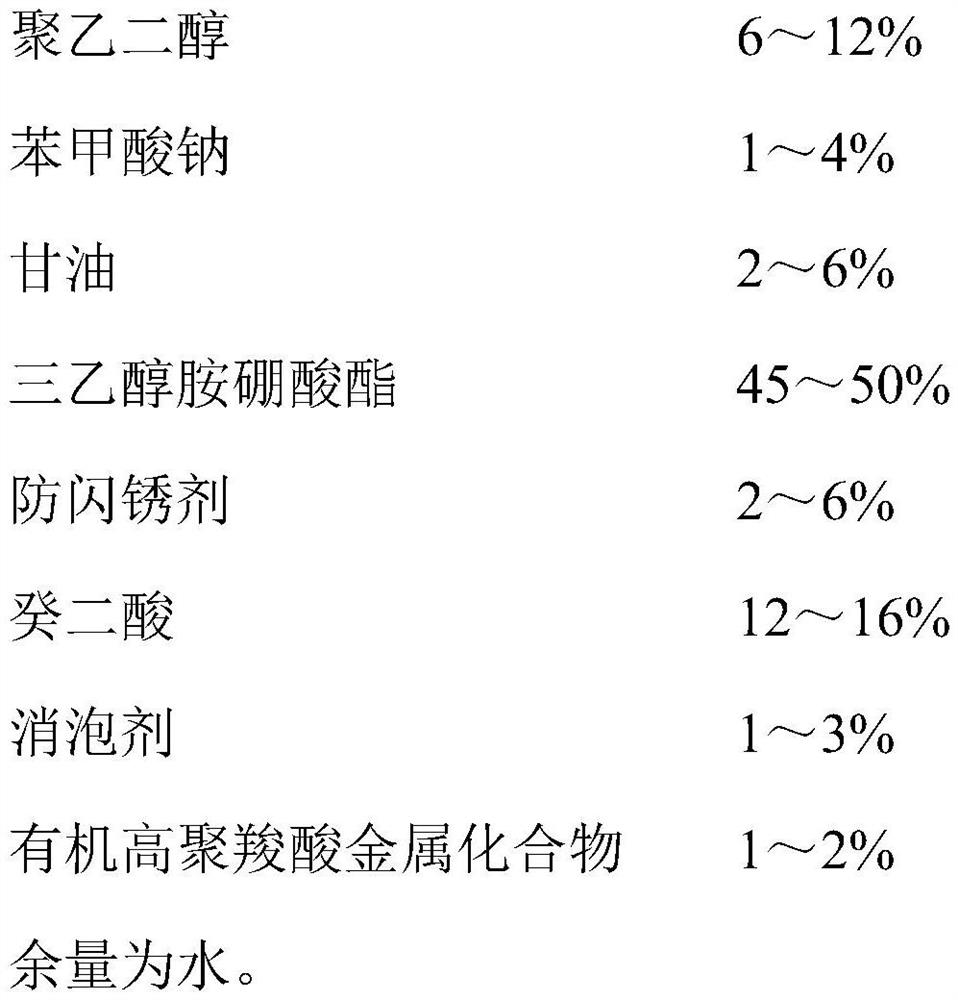

[0029] Embodiment 1 A kind of long-acting water-based antirust agent

[0030] It includes the following components by weight percentage:

[0031]

[0032]

[0033] Its preparation method is:

[0034] (1) Take the amount of water in the formula and heat it to 70°C, add the amount of sodium benzoate, triethanolamine borate, anti-flash rust agent and sebacic acid while stirring, and stir until completely dissolved to obtain the mixed solution A;

[0035] (2) After cooling the mixed solution A obtained in step (1) to room temperature, add the glycerol, polyethylene glycol and defoamer in the formula amount and stir for 80 minutes to obtain the mixed solution B;

[0036] (3) Add the organic high polycarboxylate metal compound in the formula amount to the mixed solution B obtained in step (2) while stirring, and stir for 20 minutes to obtain the water-based antirust agent.

Embodiment 2

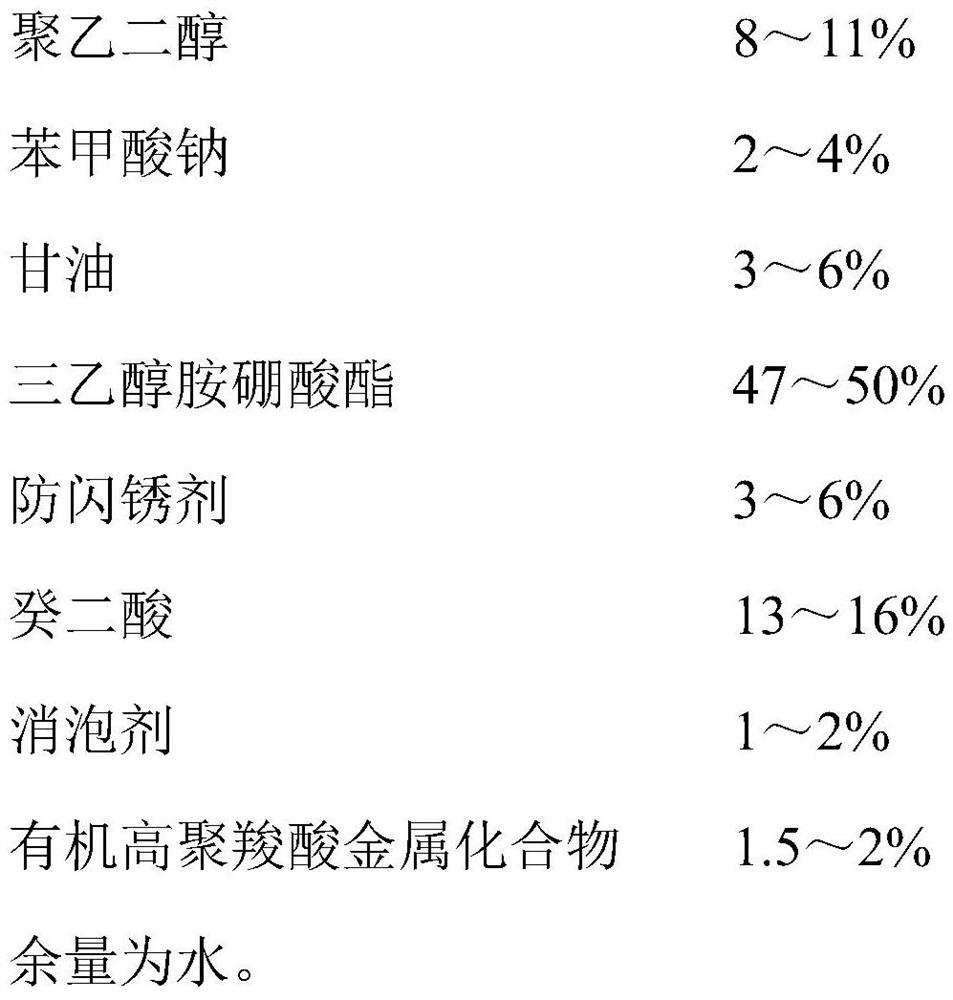

[0037] Embodiment 2 A kind of long-acting water-based antirust agent

[0038]

[0039] Its preparation method is:

[0040] (1) Take the amount of water in the formula and heat it to 50°C, add the amount of sodium benzoate, triethanolamine borate, anti-flash rust agent and sebacic acid while stirring, and stir until completely dissolved to obtain the mixed solution A;

[0041] (2) After cooling the mixed solution A obtained in step (1) to room temperature, add glycerin, polyethylene glycol and defoamer in the formula amount and stir for 40 minutes to obtain the mixed solution B;

[0042] (3) Add the organic high polycarboxylate metal compound in the formula amount to the mixed liquid B obtained in step (2) while stirring, and stir for 40 minutes to obtain the water-based antirust agent.

Embodiment 3

[0043] Embodiment 3 A kind of long-acting water-based antirust agent

[0044]

[0045] (1) Take the amount of water in the recipe and heat it to 55°C, add the amount of sodium benzoate, triethanolamine borate, anti-flash rust agent and sebacic acid while stirring, and stir until completely dissolved to obtain the mixed solution A;

[0046] (2) After cooling the mixed solution A obtained in step (1) to room temperature, add glycerin, polyethylene glycol and defoamer in the formula amount and stir for 70 minutes to obtain the mixed solution B;

[0047] (3) Add the organic high polycarboxylate metal compound in the formula amount to the mixed solution B obtained in step (2) while stirring, and stir for 25 minutes to obtain the water-based antirust agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com