Microbial oil and extraction method thereof

A microbial oil and extraction method technology, applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of low ARA and low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

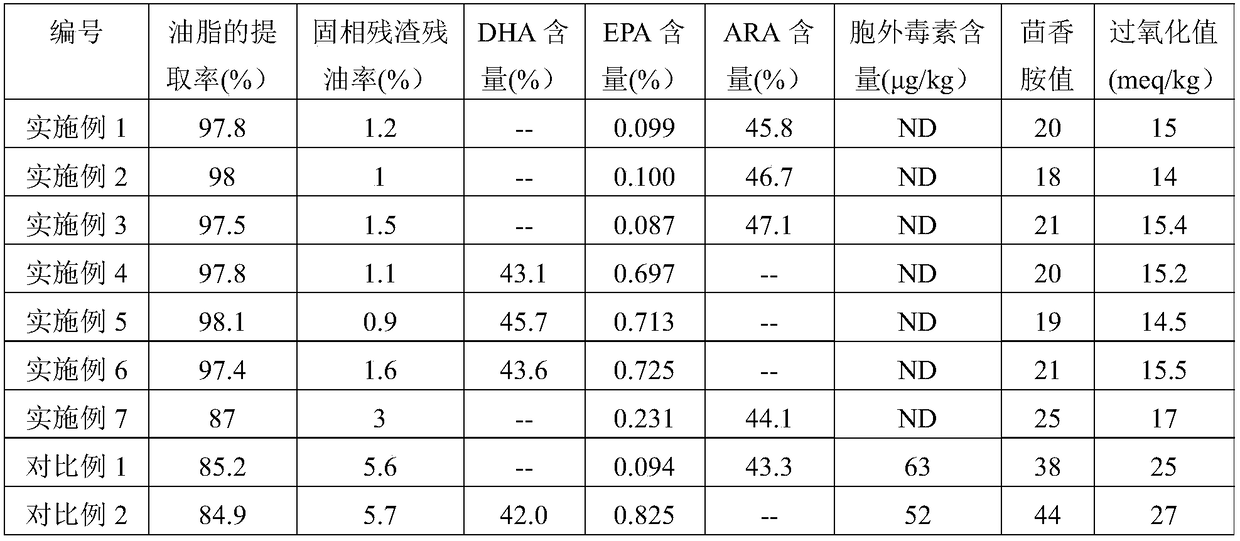

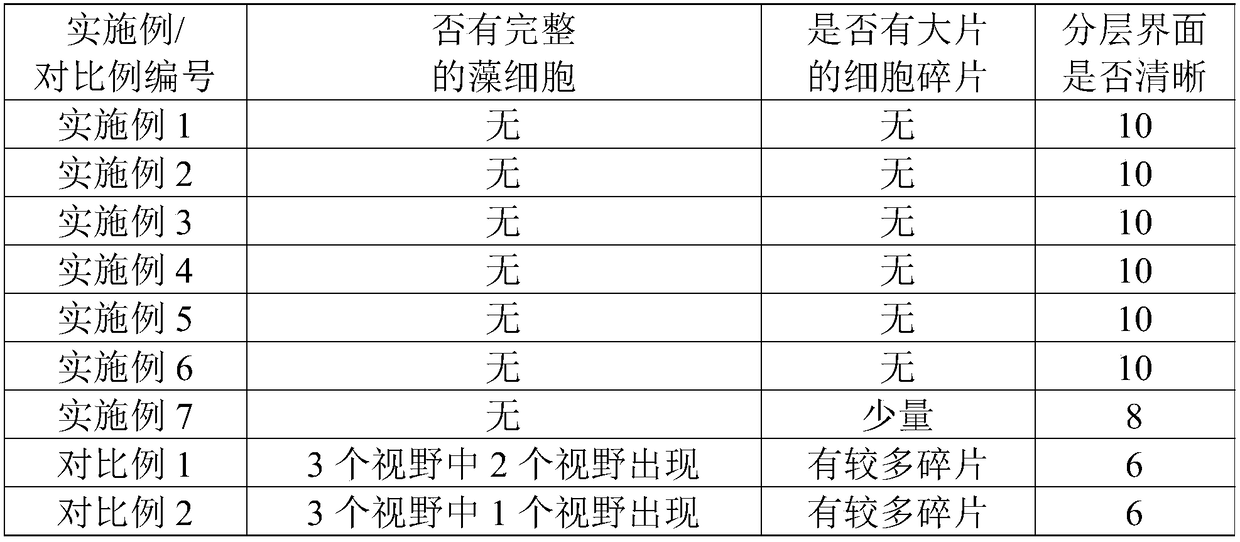

Examples

Embodiment approach

[0023] According to a preferred embodiment of the present invention, the cell wall lyase includes alkaline protease. In addition, preferably, the cell wall lyase may also include at least one of cellulase, hemicellulase, pectinase, helicase, chitinase and ligninase.

[0024] According to the present invention, the dosage of the cell wall lyase can be selected within a wide range, as long as the cell wall of the oleaginous microorganism can be fully lysed, so as to release the microbial oil. Preferably, the amount of the cell wall lyase is 1-5 g per liter of the fermentation broth.

[0025] According to the present invention, the conditions of the enzymatic hydrolysis can be the conditions conventionally used to crack the cell wall of oleaginous microorganisms by enzymatic hydrolysis, but the inventors of the present invention have found that by performing the enzymatic hydrolysis under aerobic conditions, it is possible to The enzymatic hydrolysis efficiency is further improv...

Embodiment 1

[0057] This embodiment is used to illustrate microbial grease provided by the present invention and preparation method thereof

[0058] (1) lye preparation: add 200L of demineralized water in the alkali tank, take food-grade NaOH according to the concentration of 20% by weight and put it into the alkali tank to fully dissolve it, and place the prepared lye in a pressure of 0.14MPa. Sterilize in saturated steam at 145°C for 1 hour, then pass sterile compressed air into the alkali tank to make the tank pressure of the alkali tank 0.02-0.05MPa, and pass cooling water into the jacket of the alkali tank to cool the alkali solution to 35-45℃, standby;

[0059] (2) Preparation of cell wall lysate: sterilize the series-connected secondary liquid sterile filtration system with a pressure of 0.14 MPa and a temperature of 145° C. with saturated steam for 1 h, and then use sterile compressed air to keep the pressure for standby; the sterile filtration The filter specification of the syst...

Embodiment 2

[0063] This embodiment is used to illustrate microbial grease provided by the present invention and preparation method thereof

[0064] (1) lye preparation: add the demineralized water of 200L in the alkali tank, take food-grade sodium carbonate according to the concentration of 15% by weight and drop into the alkali tank to fully dissolve, the prepared lye is placed in a pressure of 0.14MPa, Sterilize in saturated steam at 145°C for 1 hour, then pass sterile compressed air into the alkali tank to make the tank pressure of the alkali tank 0.02-0.05MPa, and pass cooling water into the jacket of the alkali tank to cool the alkali solution to 35-45°C, set aside;

[0065] (2) Preparation of cell wall lysate: sterilize the series-connected secondary liquid sterile filtration system with a pressure of 0.14 MPa and a temperature of 145° C. with saturated steam for 1 h, and then use sterile compressed air to keep the pressure for standby; the sterile filtration The filter specificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com