Preparation method of water-rich filling material for mine

A filling material and water-rich technology, which is applied in the field of mining filling materials, can solve the problems of reduced strength, poor weathering resistance and stability, and fast weathering water loss, and achieves improved strength, good water retention performance and strength. Adsorbent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

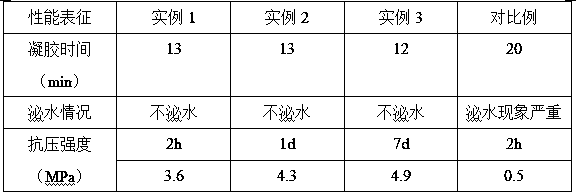

Examples

Embodiment Construction

[0019] In terms of parts by weight, weigh 60-80 parts of sulfoaluminate cement, 5-10 parts of retarder, 10-20 parts of phosphogypsum, 7-12 parts of slag, 1-6 parts of accelerator, 8- 12 parts of diatomite, 0.1-0.4 parts of polyacrylamide, 1-3 parts of polypropylene fiber, 0.1-1 part of alkaline activator, 0.1-1 part of foaming agent, 0.1-1 part of foam stabilizer, 80-100 1 part deionized water, mix sulfoaluminate cement and retarder evenly to obtain component A, mix phosphogypsum, slag, coagulant, diatomaceous earth, polyacrylamide, polypropylene fiber, alkaline activator, hair Mix the foam agent and the foam stabilizer, stir at a stirring rate of 1000-3000r / min and a temperature of 30-50°C for 2-4 hours, cool to room temperature to obtain a mixture, add deionized water and stir rapidly at room temperature for 3 minutes, and mix well to obtain B Components: Mix component A and component B uniformly at a mass ratio of 1:1, pump with a grouting pump, and pour into the filling ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com