Constructional binding material and construction material

A construction adhesive and material technology, applied in the field of construction cementitious materials and construction materials, can solve problems such as lack of active conditions, waste residue application restrictions, environmental pollution, etc., to improve the use strength and aging resistance, and prevent compression Decrease in strength or even cracking, low cost of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

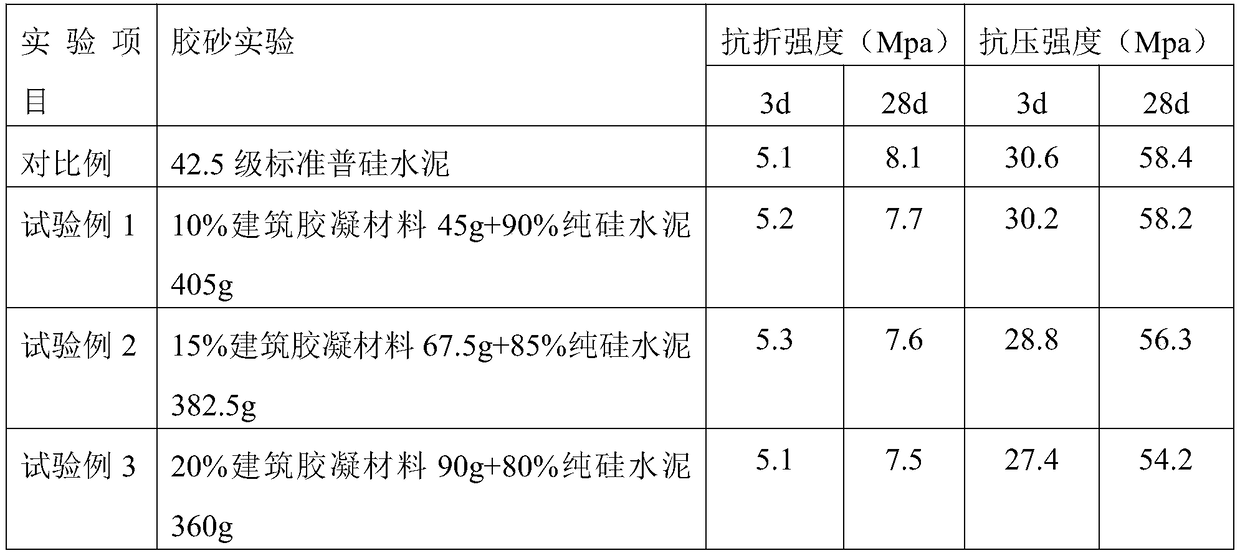

[0053] The following test examples are building materials made by blending the building cementitious material provided by the present invention with pure silicon cement according to the ratios of 1:9, 1.5:8.5, and 1:4 respectively. The test results of the performance parameters are shown in Table 1.

[0054] Among them, in the slag powder test, the 28d compressive strength of the standard ordinary silicate cement used in the comparative example is required to be 50-60Mpa. In this embodiment, the 28d compressive strength of the 42.5 grade ordinary silicate cement in the comparative example is 58.4Mpa .

[0055] In the test example, pure silica cement: its clinker (containing 5% gypsum) grinding specific surface area is 350m 2 / kg. Building cementitious material: It is made by mixing modified stainless steel refining steel slag and industrial waste slag. The grinding specific surface area of building cementitious material is 430m 2 / kg~550m 2 / kg. Wherein, in above-mention...

Embodiment 2

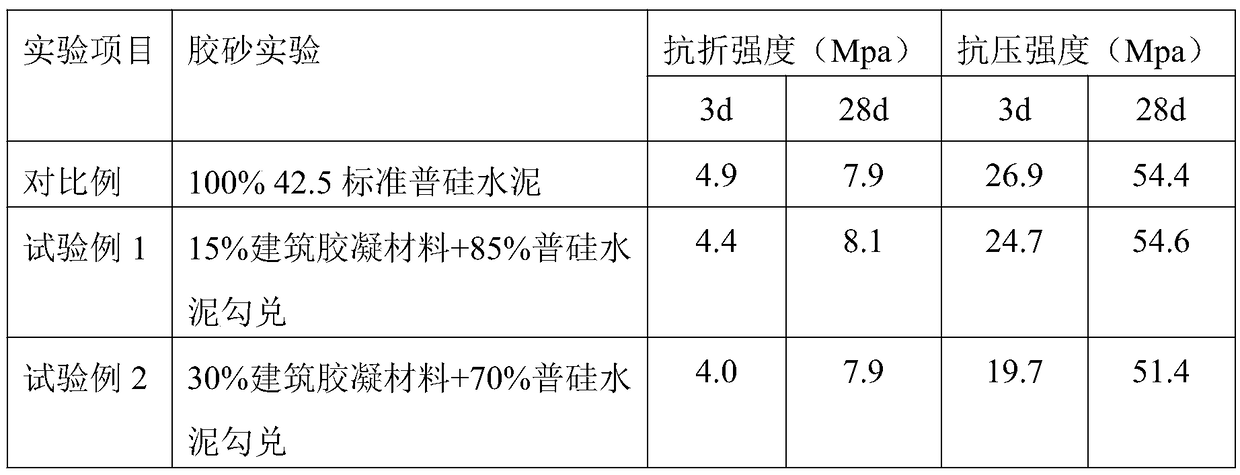

[0061] In the following test examples, the building materials made by blending 15%, 30% building cementitious material with 85%, 70% ordinary silicon 42.5 grade cement respectively, the test results of their performance parameters are shown in Table 2.

[0062] Wherein, in the comparative example, use 100% 42.5 grade standard ordinary silicate cement, its 28d compressive strength is 54.4Mpa; In the test example, 100% ordinary silicate cement: its clinker (containing 5% gypsum) grinding specific surface area is 350m 2 / kg. Building cementitious material: It is modified refined steel slag and other waste slag mixed and ground with a specific surface area of 430m 2 / kg~550m 2 / kg. Wherein, in above-mentioned test example 1-3, the specific surface area of building cementitious material is 500m 2 / kg.

[0063] Table 2

[0064]

[0065] Can see by above-mentioned test example and comparative example, use 30% construction cementitious material provided by the present inv...

Embodiment 3

[0068] The building material that is made by mixing the building cementitious material provided by the invention with concrete, the addition of the building cementitious material is 10%-15% of the total amount of cementitious material in the concrete; the 3d activity index of the building cementitious material is 77%-77.5%, and the fly ash usually used as the cementitious material of concrete, its national standard 28d activity index≧70%, that is to say, the activity index of the building cementitious material provided by the present invention is far greater than fly ash, It can be used as a substitute for some fly ash or all fly ash in concrete. It not only has a high activity index, but also can significantly improve the strength of concrete. At the same time, it has low cost of use. It can not only solve the problem of recycling steel slag, but also improve its utilization. Compared with the commonly used building material concrete, the performance of the made building mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com