Glass bracket for high-pressure kettle

A glass holder and autoclave technology, which is applied to glass/slag layered products, chemical instruments and methods, layered products, etc. Low efficiency and other problems, to achieve the effect of increasing glass loading, shortening processing time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

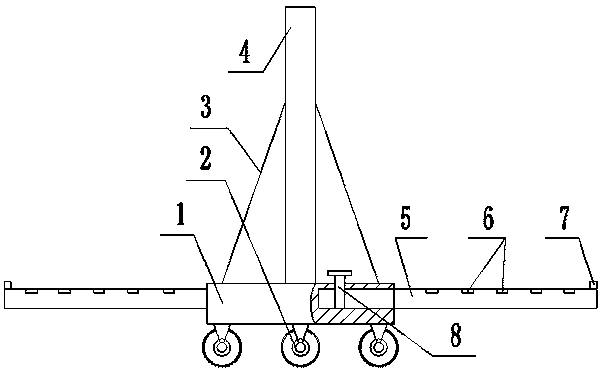

[0010] Such as figure 1 As shown, a glass bracket for an autoclave according to the present invention, the glass bracket includes a wheel 2 that matches the inner track of the autoclave and a base 1 arranged on the wheel 2, and the base 1 is provided with a vehicle frame 4, and between the vehicle frame 4 and the base 1 is also provided with a backrest slant plate 3, and the backrest slant plate 3 is provided with two, which are respectively arranged on both sides of the vehicle frame 4 in an inclined state. Support plates 5 are also provided on both sides of the base 1 , a plurality of U-shaped grooves 6 are provided on the support plates 5 , and stoppers 7 are provided at the ends of the support plates 5 .

[0011] Furthermore, in the glass bracket for autoclave according to the present invention, the support plate 5 is set as a telescopic multi-stage structure, and the plurality of U-shaped grooves 6 are equally spaced and longitudinally distributed on the support plate alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com