A kind of phenol cyanide wastewater treatment method

A wastewater treatment and phenol cyanide technology, which is applied in multi-stage water treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of unsuitability for large-scale industrialized treatment and high operating cost of phenol cyanide wastewater treatment process, and achieve a solution Severe backlog, reduced operating costs, and improved adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

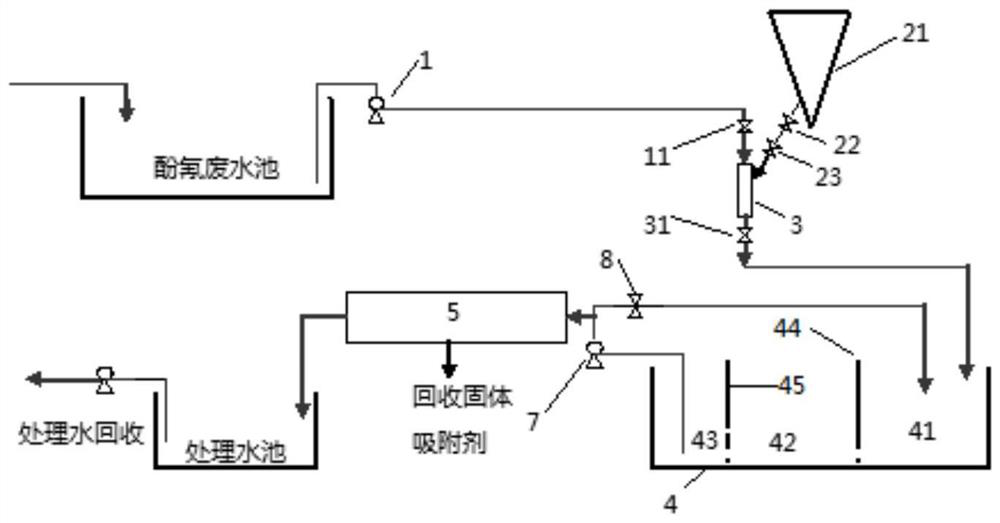

[0069] The present embodiment provides a kind of phenol cyanide wastewater treatment method, comprises the following steps:

[0070] 1. Adjust the pH of phenol cyanide wastewater to 5-7, take coke powder as a solid adsorbent, and then use 60m of phenol cyanide wastewater in a flowing state 3 The flow rate of / h flows into the ejector, and is mixed with the solid adsorbent at a flow rate of 30m / s in the ejector to obtain the first solid-liquid mixture.

[0071] Wherein, the addition of solid adsorbent accounts for 5% of the total weight of phenol cyanide wastewater.

[0072] The solid adsorbent has an average particle size of 1 mm and a porosity of 0.4.

[0073] 2. Adjust the flow rate of the first solid-liquid mixture to 0.8m / s, and flow into the adsorption pool naturally through the horizontal pipeline, and perform dynamic adsorption in the adsorption pool to obtain the second solid-liquid mixture;

[0074] A first partition and a second partition are longitudinally arrange...

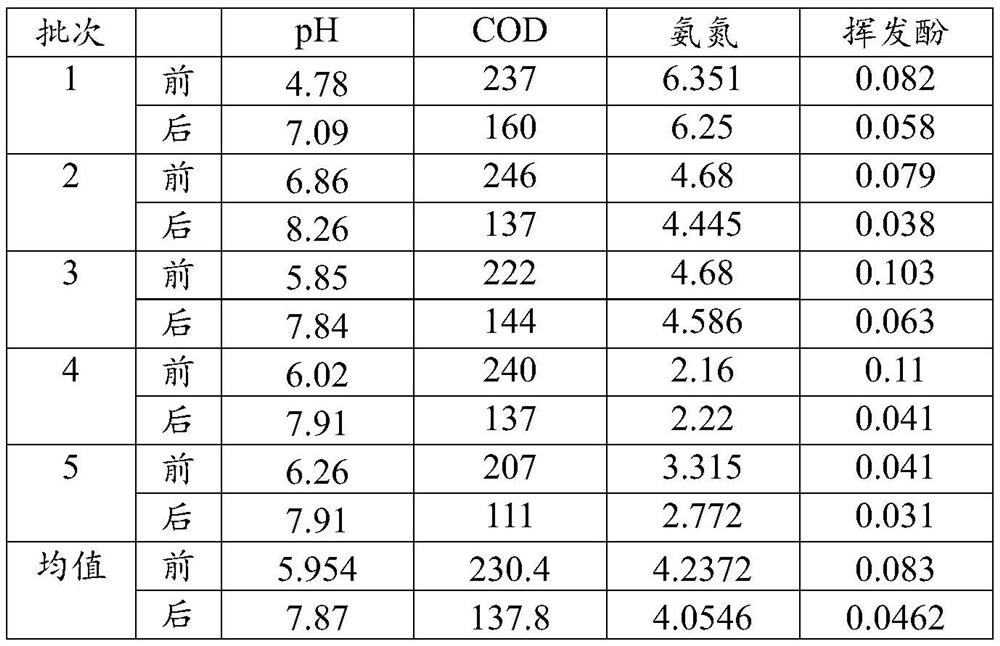

Embodiment 2

[0084] The present embodiment provides a kind of phenol cyanide wastewater treatment method, comprises the following steps:

[0085] 1. Adjust the pH of phenol cyanide wastewater to 5-7, take coke powder as a solid adsorbent, and then use 60m of phenol cyanide wastewater in a flowing state 3 The flow rate of / h flows into the ejector, and is mixed with the solid adsorbent at a flow rate of 30m / s in the ejector to obtain the first solid-liquid mixture.

[0086] Wherein, the addition of solid adsorbent accounts for 3% of the total weight of phenol cyanide wastewater.

[0087] The average particle size of the solid adsorbent is 0.48mm.

[0088] 2. Adjust the flow rate of the first solid-liquid mixture to 0.9m / s, and flow into the adsorption pool naturally through the horizontal pipeline, and perform dynamic adsorption in the adsorption pool to obtain the second solid-liquid mixture;

[0089] A first partition and a second partition are vertically arranged in the adsorption pool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com