A multifunctional grinding device

A multi-functional, grinding machine technology, applied in grinding machines, grinding slides, grinding racks, etc., to achieve the effect of simple structure, improved flexibility and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

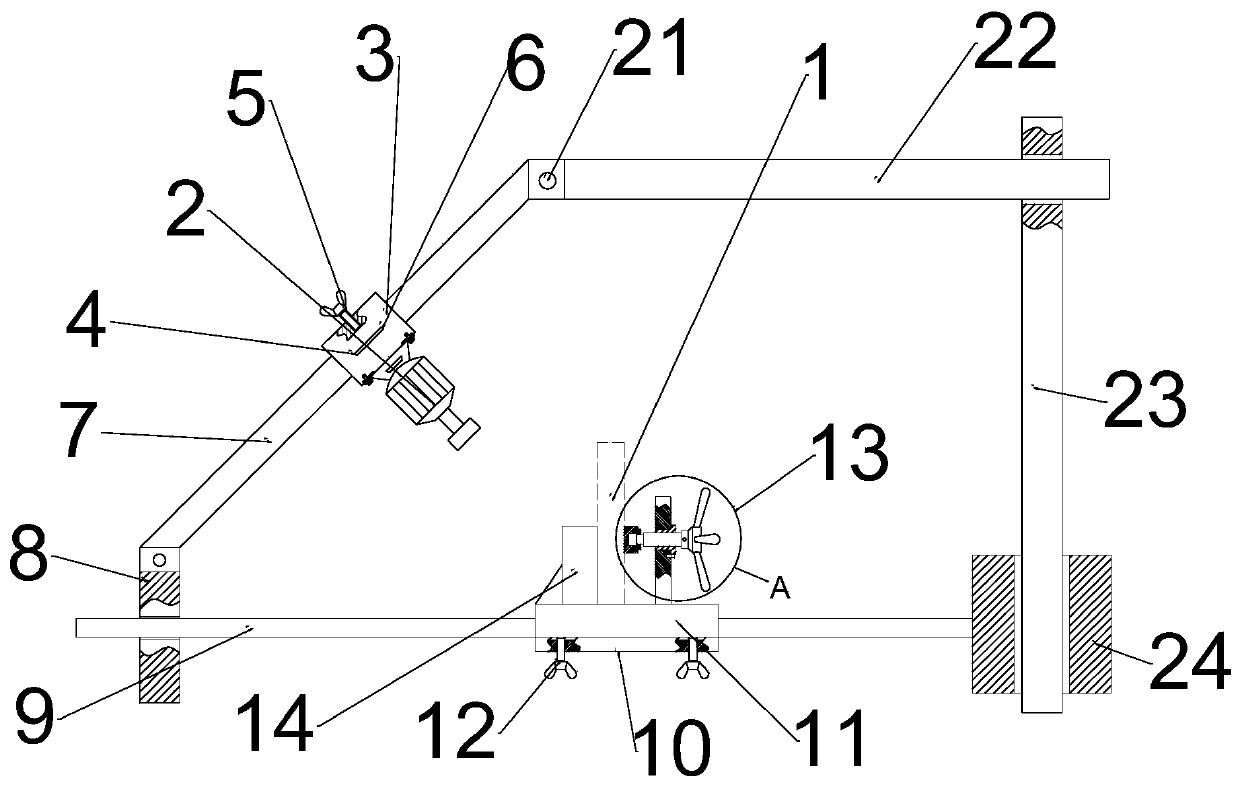

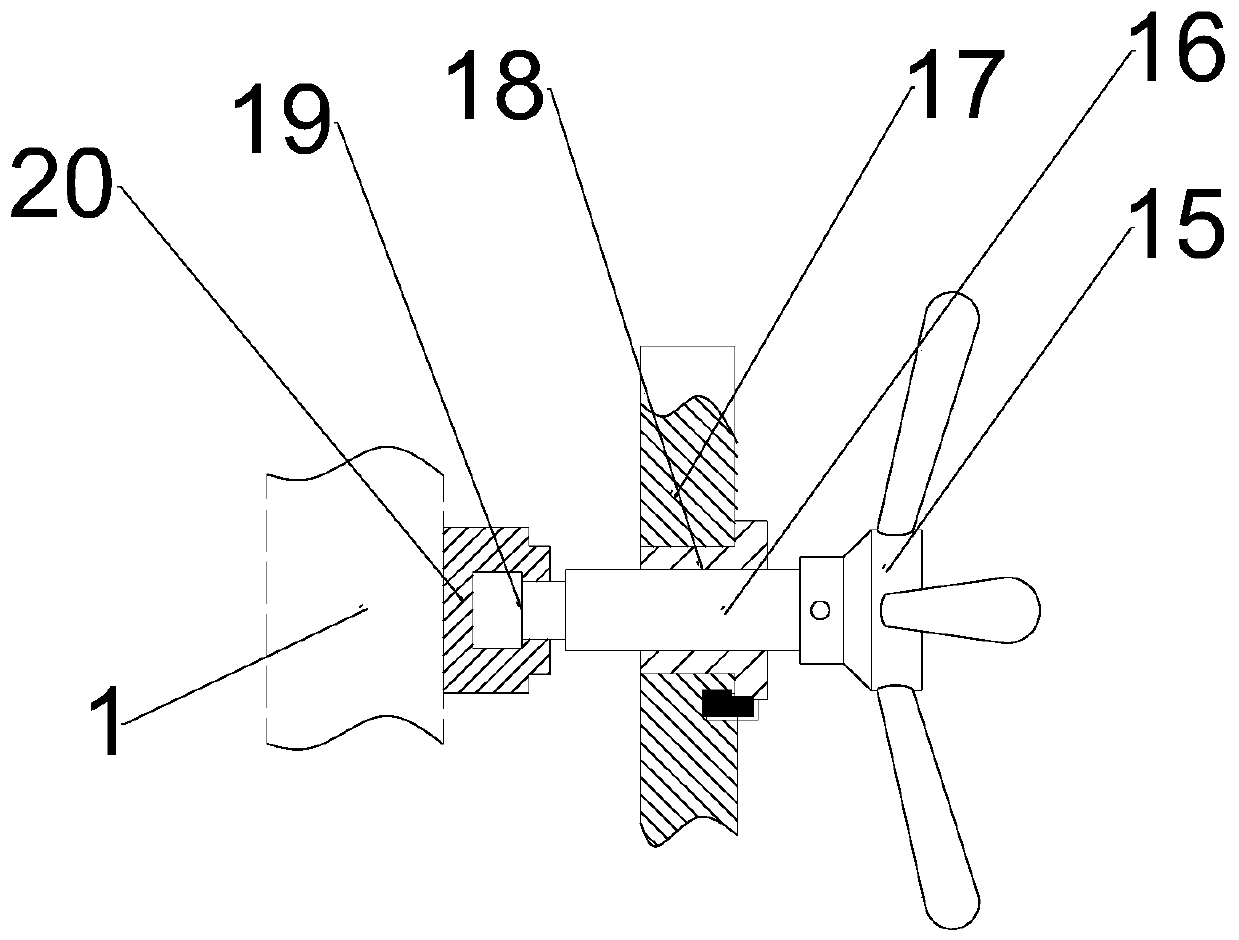

[0016] see figure 1 and figure 2 , a precise slotting device for mechanical parts, comprising a workpiece 1, a grinder 2 and a workpiece fastening mechanism 13, the grinder 2 is arranged above the workpiece 1, and the workpiece fastening mechanism 13 fastens the workpiece 1 Solid; the grinder 2 bolts are fixed on the grinder sliding mechanism 3, and the grinder slide mechanism 3 is slidably installed on the grinder slide rail 7, which can keep the grinder 2 at a certain inclination angle for grinding, and can perform chamfering Grinding operation, high grinding precision; the grinding machine sliding mechanism 3 includes a grinding machine mounting block 4, a grinding machine mounting block fastening bolt 5 and a handle 6, and the grinding machine 2 bolts are fixed on the grinding machine mounting block 4, The handle 6 is welded and fixed on the grinding machine mounting block 4, and the grinding machine mounting block fastening bolt 5 is also arranged on the grinding machin...

Embodiment 2

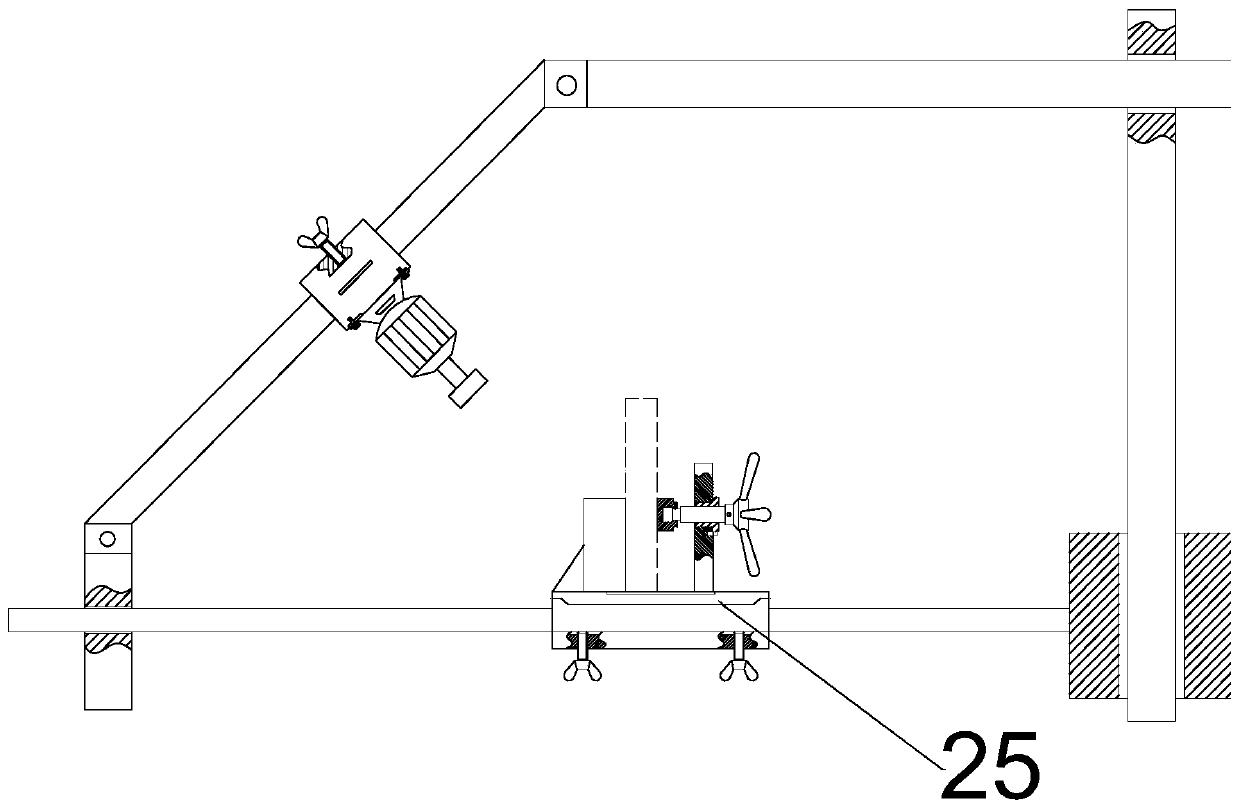

[0018] see image 3 Compared with Embodiment 1, the present embodiment 2 is only different in that the workpiece slider 11 includes the front and rear sliders 25, and the front and rear sliders 25 can make the workpiece fastening mechanism 13 slide back and forth, further improving the The flexibility of the grinding position of the grinding machine 2.

[0019] The working principle of the present invention is: adjust the grinding machine slide rail 7 to be fixed at any acute angle with the ground, then slide the grinding machine 2 on the grinding machine slide rail 7 to facilitate grinding at any angle, and simultaneously After the angle of the slide rail 7 of the grinding machine is fixed, the left and right positions of the grinding machine 2 can still be adjusted, which greatly improves the flexibility of the grinding position of the grinding machine 2; The fixed mechanism 13 can adjust the left and right positions of the workpiece 1, and further improve the flexibility o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com