Fenton-like catalytic material having double reactive active centers and preparation method thereof

A dual-reaction activity, catalytic material technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large reaction mass transfer resistance, low utilization rate of hydrogen peroxide, etc., to improve the utilization rate , Good catalytic activity, good stability, and the effect of wide pH response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

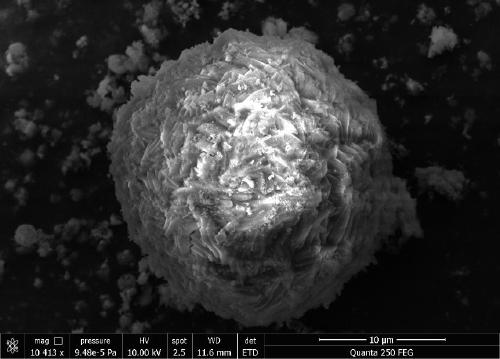

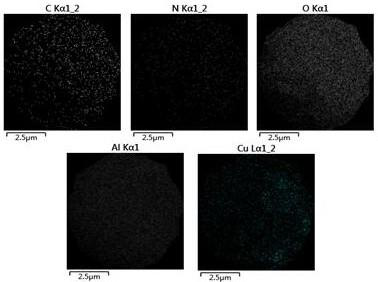

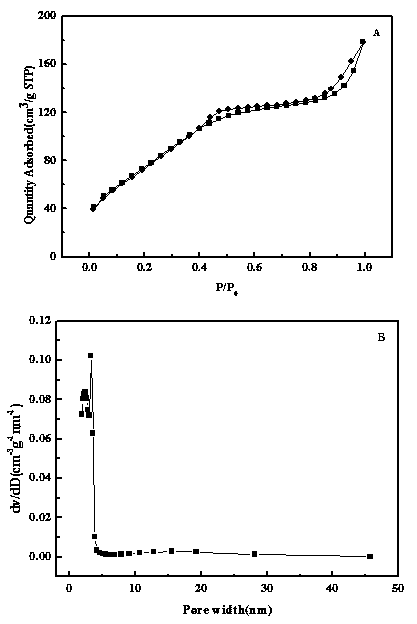

[0042] A preparation method of a Fenton-like catalytic material with double reactive active centers, comprising the steps of:

[0043] (1) Put 10g of urea into a corundum crucible, heat up to 550°C in a muffle furnace at a rate of 5°C / min for calcination, and keep it warm for 4 hours to obtain a powdery product carbon nitride A; then the product A Dissolve in deionized water and stir to form a suspension solution B; wherein the mass fraction of product A carbon nitride is 4.5%;

[0044] (2) Take 40mL of deionized water, add 6.0g aluminum nitrate nonahydrate, 0.18g copper nitrate trihydrate and 4.0g glucose, stir for 30min to form solution C;

[0045] (3) Add the suspension solution B prepared in step (1) dropwise to solution C, stir at a rate of 100r / min for 30min, then transfer it to a polytetrafluoroethylene reactor, and seal the water under the condition of 200°C After thermal reaction for 20 h, the product was washed with water, centrifuged and dried to obtain solid D;

...

Embodiment 2

[0049] A preparation method of a Fenton-like catalytic material with double reactive active centers, comprising the steps of:

[0050] (1) Put 12g of urea into a corundum crucible, heat up to 550°C in a muffle furnace at a rate of 5°C / min for calcination, and then keep it warm for 4 hours to obtain a powdery product carbon nitride A; then the product A Dissolve in deionized water and stir to form a suspension solution B; wherein the mass fraction of product A carbon nitride is 4.5%;

[0051] (2) Take 80mL of deionized water, add 6.5g of aluminum nitrate nonahydrate, 0.24g of copper nitrate trihydrate and 4.5g of glucose, and stir for 30min to form solution C;

[0052] (3) Add the suspension solution B prepared in step (1) dropwise to solution C, stir at a rate of 120r / min for 30min, then transfer it to a polytetrafluoroethylene reactor, and seal the water under the condition of 200°C After thermal reaction for 18 h, the product was washed with water, centrifuged and dried to ...

Embodiment 3

[0056] A preparation method of a Fenton-like catalytic material with double reactive active centers, comprising the steps of:

[0057] (1) Put 15g of urea into a corundum crucible, heat up to 550°C in a muffle furnace at a heating rate of 5°C / min, and then heat it for 4 hours to obtain a powdered product carbon nitride A; then the product A Dissolve in deionized water and stir to form a suspension solution B; wherein the mass fraction of product A carbon nitride is 3.0%;

[0058] (2) Take 60mL of deionized water, add 7.0g aluminum nitrate nonahydrate, 0.35g copper nitrate trihydrate and 5.0g glucose, stir for 30min to form solution C;

[0059](3) Add the suspension solution B prepared in step (1) dropwise to solution C, stir at a rate of 150r / min for 30min, then transfer it to a polytetrafluoroethylene reactor, and seal the water under the condition of 200°C After thermal reaction for 18 h, the product was washed with water, centrifuged and dried to obtain solid D;

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com