Water-cooled reactor for methanol synthesis

A methanol synthesis and reactor technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as project investment reduction, achieve the effects of reducing equipment investment, avoiding difficult control, and maintaining productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

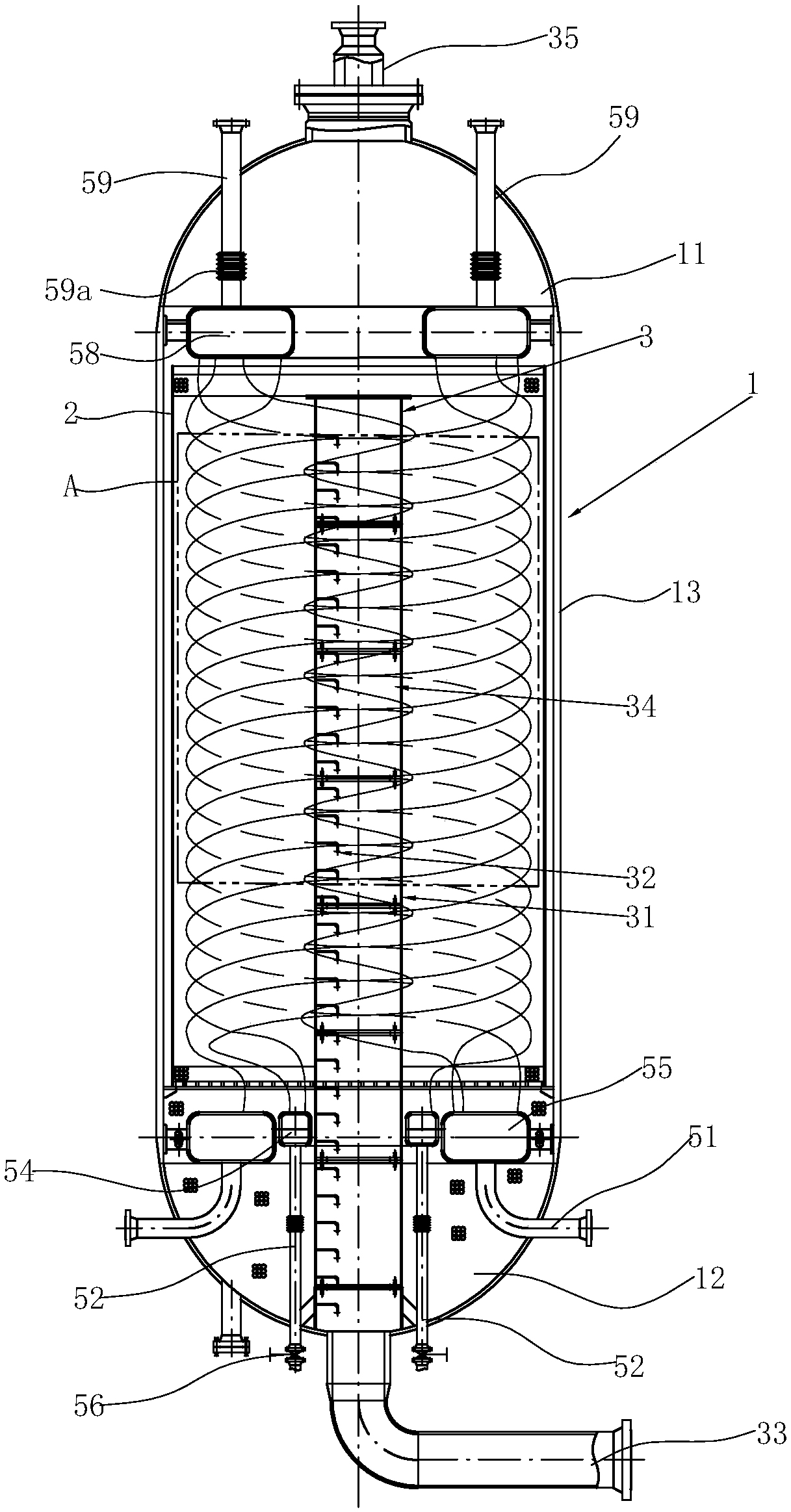

[0033] Such as Figure 1 to Figure 3 As shown, the water-cooled methanol synthesis reactor includes:

[0034] The furnace body 1 is a conventional structure, including an upper head 11 , a lower head 12 and a cylinder 13 connected between the upper head 11 and the lower head 12 .

[0035] The catalyst frame 2 is arranged in the cylinder body 13 . The catalyst frame 2 can be any one of the prior art according to the needs. This embodiment is a radial reactor, and the raw material gas enters the catalyst frame from the side wall of the catalyst frame 2 . The feed gas enters the synthesis gas collection pipe 3 after undergoing methanol synthesis catalytic reaction.

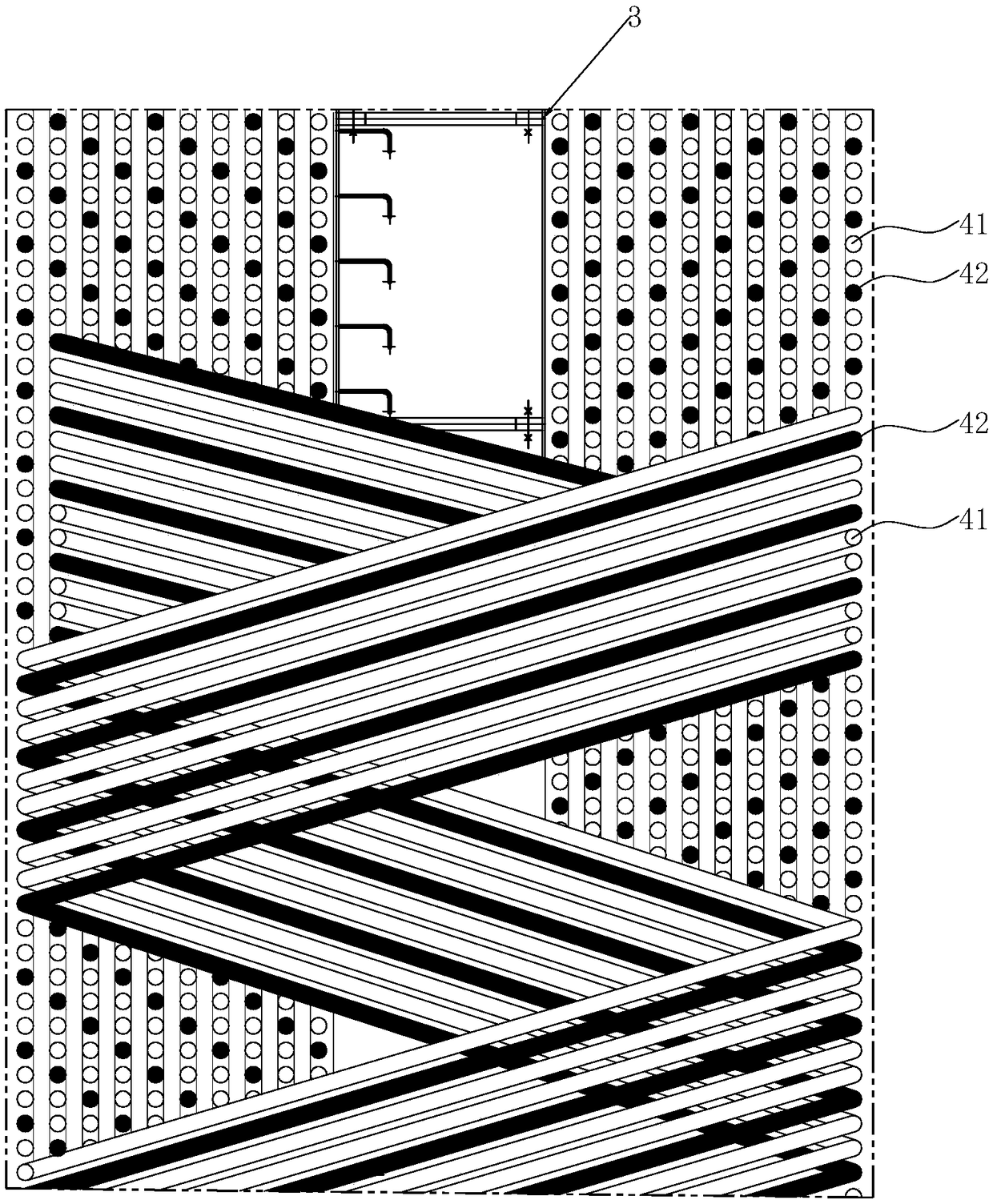

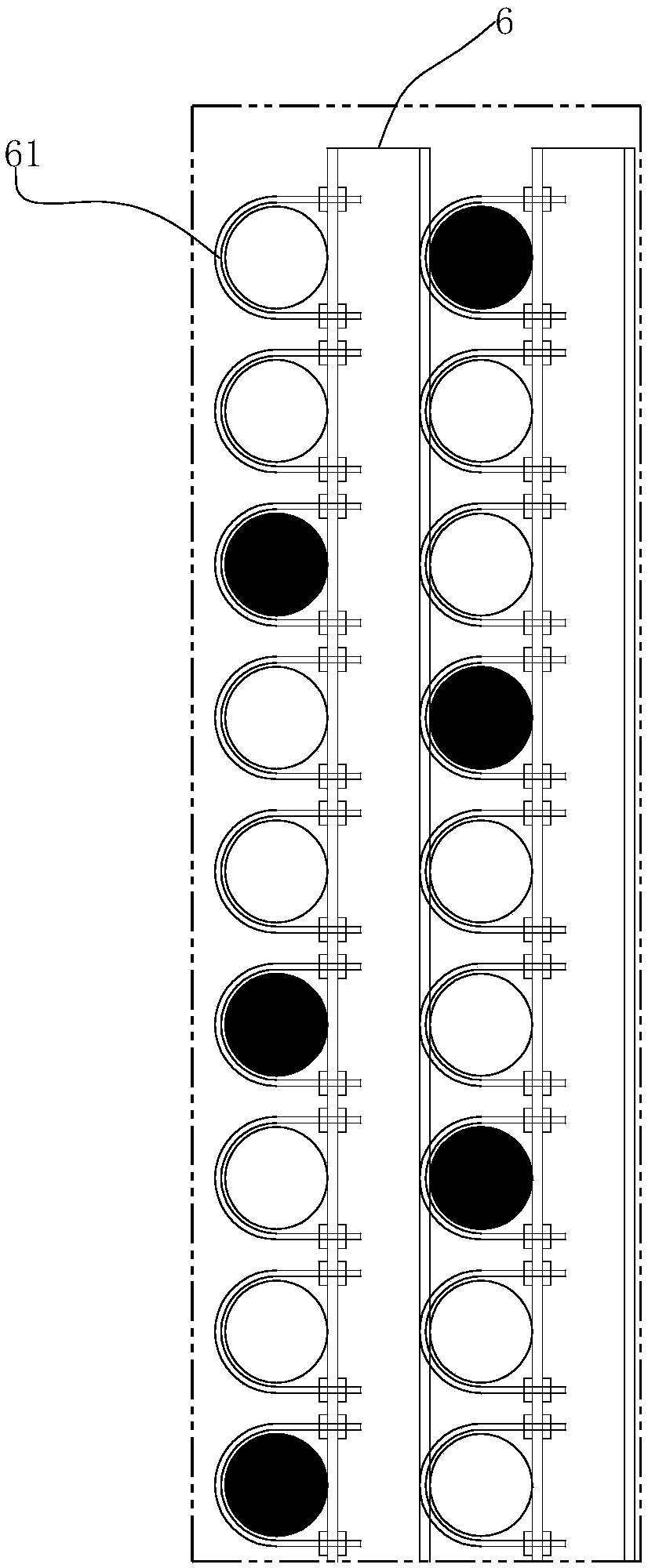

[0036] The synthesis gas collecting pipe 3 is used to collect the synthesis gas. It is arranged in the middle of the cavity of the catalyst frame 2 and is composed of multiple cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com